A small point to consider with the full throttle pressure seemingly less than before the oil change and the addition of the cooler (did I get that right?) is that the cooler may have a high pressure drop across it at high pump output which is proportional to RPM. I put a high quality (?) aircraft cooler on my WRC car at one point because it fit perfectly where I wanted it to go and I thought it was very efficient at BTU removal. Boy was I wrong! Size and efficiency were OK, but the thing had a huge pressure drop that caused me to lose amost 20 psi at high RPM. Reworked everything to fit larger normal race car type of cooler and pressure came back to normal. Don't mean to imply that SOS part is not good quality, but it might be worth asking for a flow/pressure drop graph if they have one.

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

oil pressure with 15w50

- Thread starter CL65 Captain

- Start date

I believe it is a un-badged B&M cooler. I guess I will have to buck up and get an oil pressure gauge. I'm think of the SPA dual gauge - oil pressure/temp.

Last edited:

A small point to consider with the full throttle pressure seemingly less than before the oil change and the addition of the cooler (did I get that right?) is that the cooler may have a high pressure drop across it at high pump output which is proportional to RPM. I put a high quality (?) aircraft cooler on my WRC car at one point because it fit perfectly where I wanted it to go and I thought it was very efficient at BTU removal. Boy was I wrong! Size and efficiency were OK, but the thing had a huge pressure drop that caused me to lose amost 20 psi at high RPM. Reworked everything to fit larger normal race car type of cooler and pressure came back to normal. Don't mean to imply that SOS part is not good quality, but it might be worth asking for a flow/pressure drop graph if they have one.

There is a balance between flow rate and core efficiency with any heat exchanger. For an air-to-water, I would have probably opted for a tube-fin design over a stacked-plate design, ideally one that was specifically designed for a hostile environment like motorsports competition. These tend to provide the highest BTU transfer rate, with the least amount of resistance to high volume flow which usually nets the best overall system efficiency. However, recognize that they only work so long as you can maintain the aero. From what I have been told- a water-to-air laminova wate-to-oil cooler is probably the most preferable design for the average track enthusiast at HPDE's, as the oil comes up to temp and then just stays there regardless to how they are driving the vehicle.

I believe it is a un-badged B&M cooler. I guess I will have to buck up and get an oil pressure gauge. I'm think of the SPA dual gauge - oil pressure/temp.

I might add that if budget is a concern, there is no need to spend four times as much on a fancy dancy digital. Just a basic Autometer gauge for like $40 is perfectly adequate. The stock sender can be undependable, and the gauge difficult to interpret- so all that really matters is you have one. You might find that everything is great, but you don't know until you know, and why speculate on how the motor is operating when you can know for certain?

Last edited:

Just switched the oil and filter to Royal Purple 10w40.

OEM gauge went back to reading pretty close to what it was before.

2 at idle 5.5 while accelerating.

It appears (and I say appears because I am using the OEM gauge) that the 15w50 was the culprit. How much, I have no idea because of the accuracy of the gauge. However, since the OATs for this weekend will be in the low 70s I feel more comfortable running the 10w40 with the oil cooler and accusump (8qt total) until I can get a pressure and temp gauge to see what is going on.

John - I figure if I am going to do it, I might as well do it right the first time. The SPA dual gauge will read oil pressure and temp on one gauge.

And I believe you can program the limits for the warning lights. And you know us pilots - we like warning lights, and knobs - lots of knobs.

Plus you can get them orange lit with black background.

OEM gauge went back to reading pretty close to what it was before.

2 at idle 5.5 while accelerating.

It appears (and I say appears because I am using the OEM gauge) that the 15w50 was the culprit. How much, I have no idea because of the accuracy of the gauge. However, since the OATs for this weekend will be in the low 70s I feel more comfortable running the 10w40 with the oil cooler and accusump (8qt total) until I can get a pressure and temp gauge to see what is going on.

John - I figure if I am going to do it, I might as well do it right the first time. The SPA dual gauge will read oil pressure and temp on one gauge.

And I believe you can program the limits for the warning lights. And you know us pilots - we like warning lights, and knobs - lots of knobs.

Plus you can get them orange lit with black background.

Last edited:

Just switched the oil and filter to Royal Purple 10w40.

OEM gauge went back to reading pretty close to what it was before.

2 at idle 5.5 while accelerating.

It appears (and I say appears because I am using the OEM gauge) that the 15w50 was the culprit.

Couple questions-

- Are you sure the fill levels were the same?

- Are you sure the oil is completely up to circuit temp when you are taking your reading, and if so how are you determining this without an oil temp gauge?

(i.e. did you run a track day today? You are not taking these readings on a residential street/highway warm at like 210 degrees, are you? I thought the discussion being had was on-track under severe load)

Last edited:

Couple questions-

- Are you sure the fill levels were the same?

- Are you sure the oil is completely up to circuit temp when you are taking your reading, and if so how are you doing this without an oil temp gauge.

(i.e. did you run a track day today? You are not taking this reading on a residential street/highway warm at like 220 degrees, are you? It seems logical to me that having the higher viscosity- the 50W is going to be relatively thicker/more resistant to flow under these conditions, and in turn would develop less pressure when it is not up to the proper operating temp for which it was intended)

Fill levels are identical. Just above the full hole.

I have a little secret test track near me - they lengthened one of the runways at the airport and had to buy out a whole neighborhood. The houses were torn down but the roads remained. :biggrin:

It was hot enough that my oil cooler fan was on after a 10 min drive home and shutting off the car ~ it stays on until the thermostat gets below 175. John, I have no way of knowing without a gauge, however it appears to be that the 10w40 is showing closer OEM gauge readings to what I had prior to the oil cooler and 15w50 change. Since the only thing that changed is the oil..... I can theorize that it was the oil, however until I can get empirical data, I don't know for sure.

As I said before with OATs of low 70 and the oil cooler, I think the 10w40 will be fine for this weekend until I can get a gauge. I use to fly for Penske Racing South, so I left a message for one of my old friends that still works for them and see what he thinks. He was in charge of the Mercedes Indy (actually it was built by Ilmor Engineering and Mercedes just payed to put their name on it) engine development before they outlawed it. I know it's apples and oranges - but he knows a thing or two about engines.

Attachments

Last edited:

Fill levels are identical. Just above the full hole.

I have a little secret test track near me - they lengthened one of the runways at the airport and had to buy out a whole neighborhood. The houses were torn down but the roads remained. :biggrin::biggrin:

It was hot enough that my oil cooler fan was on after a 10 min drive home and shutting off the car ~ it stays on until the thermostat gets below 175. John, I have no way of knowing without a gauge, however it appears to be that the 10w40 is showing closer OEM gauge readings to what I had prior to the oil cooler and 15w50 change. Since the only thing that changed is the oil..... I can theorize that it was the oil, however until I can get empirical data, I don't know for sure.

That makes sense to me. The thermostat for the fan trips at 175F per their product brochure. Per my math, at 175-210 degrees (i.e. 79C - 98C), the Viscosity of M1 15W50 would be somewhere between 38 and 19.1. A significant difference from the RP 10W40 of 27.7 - 14.4 all other things being equal. You reported going from 6 to 4 mark at WOT, assuming it is correct, a healthy percentage drop. Well, aknowledge that you are running a comparably thicker oil at that target temp.

In short, my best guess here is that you are just not getting it hot enough, long enough to warrant that weight- and the consequence is your really operating it "cold" when you think it is "hot". The significant variable- I would think your cooler would be good for a 30F drop, but I can't say for sure.

It's another instance, where the actual usage is key. As I mentioned in the other thread, I agree a quality 40W with a wider operating range is probably more appropriate for your usage and get you closer to the mnfg. intended operating viscosity, but even then you might fall on the high or low side of that. Let us know once you have the temp gauge installed and really push it on the track in typical conditions. That will end a lot of the speculation.

Last edited:

I would like to state that 265*F at the pan is significantly different than 265*F post oil cooler.My experience, 265 is not in anyway uncommon for a probe in a stock NSX pan. That is consistent with other people's experience. Even with the thicker oil for protection, you are going to be nestled at the upper allowable limit. If your cooling system is not performing ideally, if it creeps hotter, if you are nose to tail and not getting enough airflow across your radiator, if you are just slow and reving it up all the time, if you have FI- and you have thinned the hell out of a 30W... your charts are going to look a lot worse than mine, and 320F is possible at which point you are going to basically be running a 0 weight oil through your engine. That's what NA looks like.

A lot of the discussion is also relative to where the oil temperatures are being taken and if they are taken from a sandwhich adapter, are the temps being measured pre or post cooler?

Many race teams prefer to measure the oil temp post cooler that is going into the motor, and 265*F here would be much more of a concern than 265*F in the pan.

I would like to state that 265*F at the pan is significantly different than 265*F post oil cooler.

A lot of the discussion is also relative to where the oil temperatures are being taken and if they are taken from a sandwhich adapter, are the temps being measured pre or post cooler?

Many race teams prefer to measure the oil temp post cooler that is going into the motor, and 265*F here would be much more of a concern than 265*F in the pan.

Absolutely a relevant point. This is why I try to be specific/detailed, so people can make reasonable deductions.

I currently have my Bosch sender in my oil pan, I acknowledge others probably are using a fitting on a sandwich adapter below the stock doughnut cooler.

Here is the response from my friend...

Jim, first off get some gauges and an oil analysis done and send me the info. As an engineer, I don't like to make generalizations without having data in my hand. However, in the mean time run a 30w oil. You will do more harm running a 50w than the proper spec 30w even if it's running hot. I don't know where people have gotten the idea to run 50w oils in production cars on the track. The key is to control your oil temperatures, not to change oil viscosity to band aid the problem. This is treating the symptom instead of the problem. Even though a closed loop water/oil exchanger is more efficient, your oil cooler is a step in the right direction. I am not familiar with Honda's C32B, but I still have some contacts at Honda Performance Development from when I was working on the HI7R. Let's wait and see what the results are of your data and we can go from there.

Jim, first off get some gauges and an oil analysis done and send me the info. As an engineer, I don't like to make generalizations without having data in my hand. However, in the mean time run a 30w oil. You will do more harm running a 50w than the proper spec 30w even if it's running hot. I don't know where people have gotten the idea to run 50w oils in production cars on the track. The key is to control your oil temperatures, not to change oil viscosity to band aid the problem. This is treating the symptom instead of the problem. Even though a closed loop water/oil exchanger is more efficient, your oil cooler is a step in the right direction. I am not familiar with Honda's C32B, but I still have some contacts at Honda Performance Development from when I was working on the HI7R. Let's wait and see what the results are of your data and we can go from there.

Last edited:

Here is the response from my friend...

However, in the mean time run a 30w oil. You will do more harm running a 50w than the proper spec 30w even if it's running hot.

Hmm. I throughly disagree with that statement. I believe that the choice of viscosity should be based on your oil's hot track temp. All oil's viscosity drops exponentially as its temp increases.

Taking data straight from the manufacturer's websites, Mobil 1 5w30's viscosity is 64.8 cSt at 100F, 11.3 at 212F, and 3.09 at 300F. The engine was designed to operate near 212, and thus the recommended oil has a nominal viscosity of about 10-11 cSt at this temp. But, if on the track, your oil temp is significantly higher than 212F the nominal xw30 viscosity will be in turn be far lower.

From Mobil's website, their 15w50's viscosity is 131.2 at 100F, 18.1 at 212F, and 4.5 at 300F. Thus, the oil has a pretty high viscosity at 212F relative to the factory fill xw30. So, if your oil temp averages around 270F or so, its viscosity is much nearer the nominal 10-11 cst than that of a xw30.

Here

I don't know where people have gotten the idea to run 50w oils in production cars on the track.

Frankly, for the vast majority of "track enthusiasts" they could probably fill their car with baby oil and be ok. The format of HPDE's, coupled with the driver caliber frequently doesn't lend itself to the same degree of high sustained temps, and thus stresses as longer road races. Plus, many are still mostly street driving their cars.

Ask Phoenix what they use in their Nationally prepared T1 Corvette and they are going to hand you a bottle of M1 15W50 on GM's factory recommendation beause it's not uncommon for them to push 280F even with an oil cooler. Same with Bondurant. Ask American Honda if they use the same spec in their Civic SI's at run-offs that they give to soccer moms. I believe the short of it is that it comes from decades of motorsports experience, and a lot of spun bearings.

A rough rule of thumb is oil temp <240F, use xw30, oil temp 240-270F, use xw40, oil temp > 270F, use xw50.

The key is to control your oil temperatures, not to change oil viscosity to band aid the problem. This is treating the symptom instead of the problem.

I completely agree with that statement. While some limited race classes will not permit such modifications, for a track toy you are certainly permitted to change / re-engineer the car as you see fit. Adding the cooler was a good idea, and perhaps you got a 20-30-35F drop. I don't know- I think it would have been helpful to have a before/after picture of what your actual temps look like in similar conditions so you could gauge the effectiveness of the mod. Maybe Chris or Shawn can get tell you what they feels the cooler is good for? It doesn't say on the site so I wouldn't know.

I am not familiar with Honda's C32B, but I still have some contacts at Honda Performance Development from when I was working on the HI7R.

Fair enough. The HPD H17R V8 runs on ethanol as I recall. I would speculate in Indy that if they can achieve a little added fuel economy and pick up a 1/2mpg so not have to taken an extra pit, or achieve a higher output- then they probably are willing to do that with some special blend and oil conditioning. They probably have like 100 people working on it with 10000X the aveage HPDE enthusiast budget.

Let's wait and see what the results are of your data and we can go from there.

That's what both me and Billy said. Once you get some figures, let everyone know what they are, and we'll do our best to make sure you are running the right stuff. :smile:

Last edited:

Hey John, he won't tell me who is now working for but he said it will be a new manufacturer entry into AMLS. He said that everyone will be completely shocked when it is finally announced. I have no idea as he was mum about it, but a wild guess.... Hyundai????

If it's the car I was suppose to test, its a european manufacturer.

Since I hear it gets hot out at Willow Springs....and I have a 91 NSX NA with E/H/I and 125K miles....should I stick with 10/30 Mobil 1 Syn or should I go with 5/30 Mobil 1 Syn? And should I use the regular Mobil 1 Syn or the Mobil 1 Syn for engines with over 100K? Or does it matter?

Tony

Tony

That's a big (2+ year) bump there! :biggrin:

Brian

Brian

Right now the hotness around a lot of trackrat circles in affordable oils is Shell Rotella T6 5w40

Everything I've been read about it points to it being a pretty awesome oil, especially for what it costs. (usually can be found for around $20/gal)

I just switched my NSX to it this summer, it's only got one track day and about 1500 miles on it so far, I plan on getting UOA of it when it's time to change it and will be sure to share.

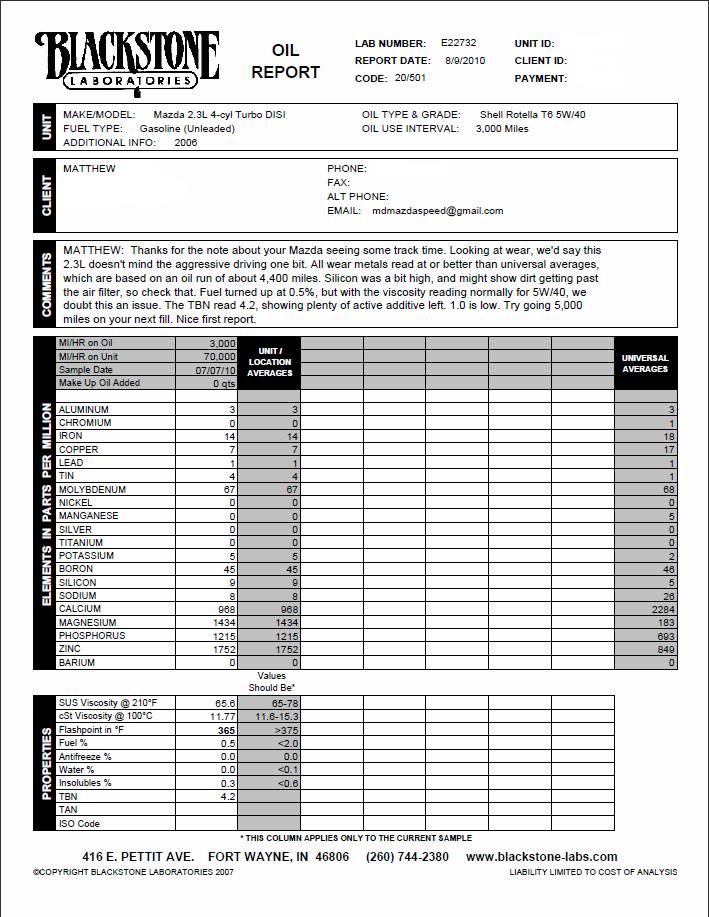

Here is a UOA of it from a Mazdaspeed6 after some decent abuse.

Look at that zinc and phosphorus!

And here is another from a turbo miata with 5hr+ of track time

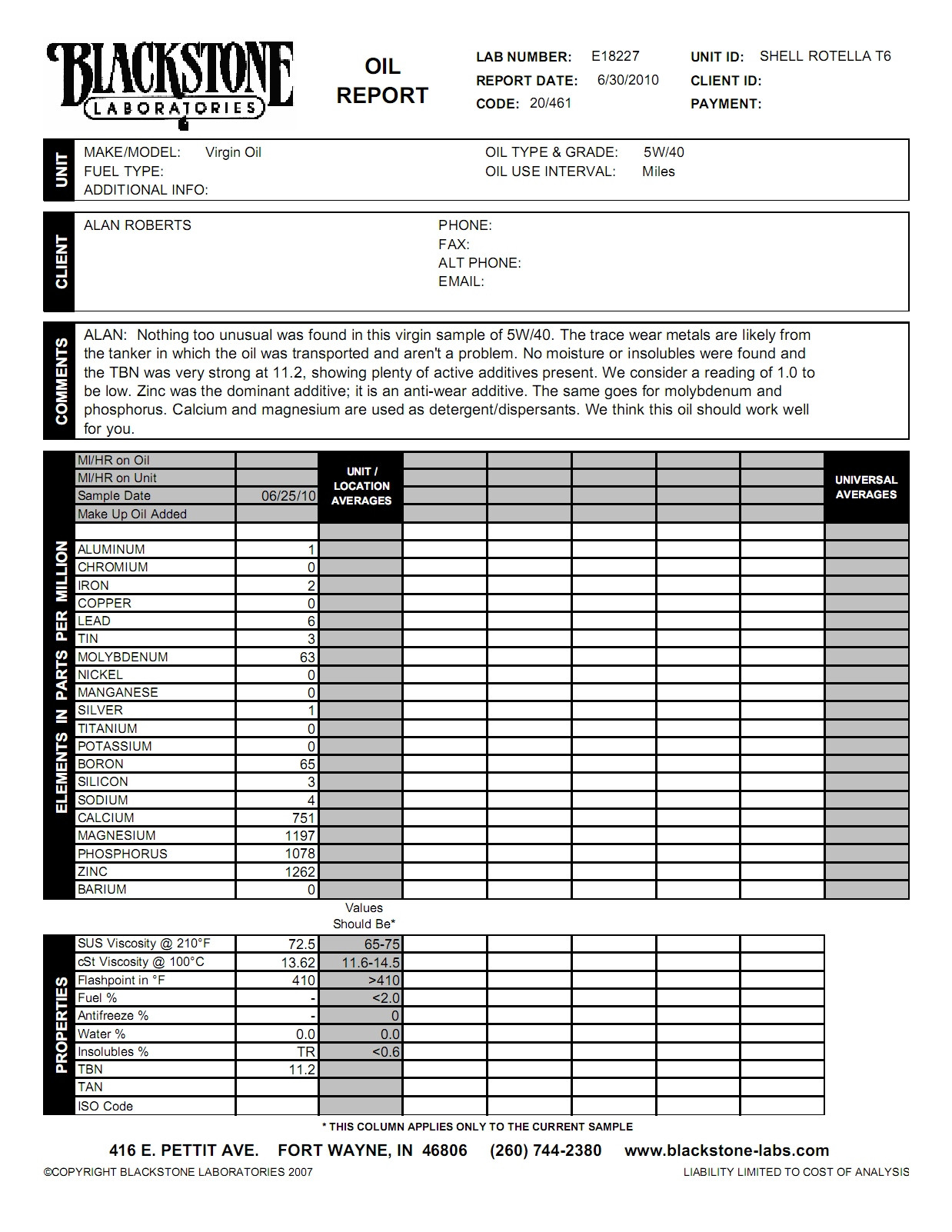

And here is a virgin OA for it.

Everything I've been read about it points to it being a pretty awesome oil, especially for what it costs. (usually can be found for around $20/gal)

I just switched my NSX to it this summer, it's only got one track day and about 1500 miles on it so far, I plan on getting UOA of it when it's time to change it and will be sure to share.

Here is a UOA of it from a Mazdaspeed6 after some decent abuse.

Look at that zinc and phosphorus!

Here's the UOA I had done of Shell Rotella T6 5W-40, after 3000 miles, and quite a bit of tracking.

Oil type with viscosity - Shell Rotella T6 5W-40 Fully Synthetic

Miles on the oil - 3000, 2 months, 150-200 track miles

Vehicle type/engine - 06 Mazdaspeed6, 2.3L turbo direct injection 70,000 miles

Driving conditions - normal/sprinted, 50/50 highway/city, summer temps 70-90F.

Track conditions - 1 day oil temps @ 260-275F for 1.5hrs, 1 day @ 250F for 1hr, ambient temps 70-90F

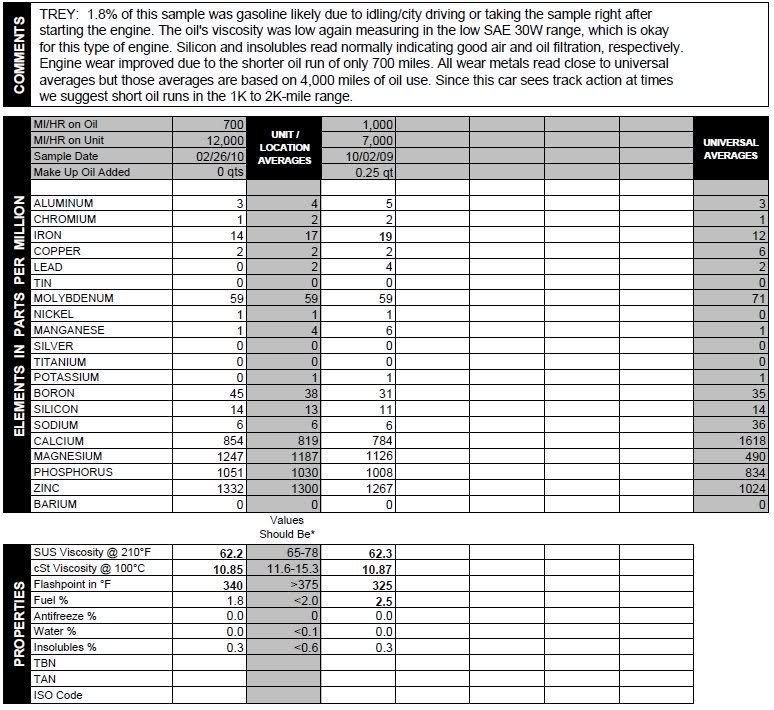

And here is another from a turbo miata with 5hr+ of track time

Here is 5-hours of track time on my turbo miata with 250* oil temps on Rotella T6 Synth

And here is a virgin OA for it.

That's what I use on my loosely built Corvette engine - NOT my NSX.

Keep us updated on how it works out for you!

Dave

Keep us updated on how it works out for you!

Dave

Is this safe to use for FI setups?

I added a SOS oil cooler and switched to 15w50 Mobil 1.

My OEM gauge usually reads 2 at idle, 4 cruising and 6 under full acceleration.

Now it reads 2 at idle, 4 cruising and 4 at full (on the track too).

Thinking about switching to Mobil 1 0w40 or RP 10w40 since the SOS oil cooler is doing a good job of keeping the temp in check.

Any thoughts????

AN10 Hose ..if you want to keep OIL flow same as OEM you need to drill

3 pieces 6 mm holes to adapter .

AN12.. 2 holes to adapter is needed to avoid OIL pump relief valve"problems"

If you dont ...you have very high presure on oil pump...this will put

lots of stress to stock oil pump ! And upper part of engine does not have presure what it should be.

Even with these "by-pass" holes there is still lots of oil flow tru oil cooler.

NSX HAS 17 mm ID oil lines so dont restrict your oil flow !

Agreed. OEM inner oil pump passageway diameters are 3/4", or 12AN.

The Honda engineers sized our oil pump gerotors, bypass spring, oil filter recommendation, and oil viscosity recommendation based on service temperature (in the service manual), and ultimately the engine bearing clearances and valvetrain requirements (VTEC, etc).

You can go with a "thinner" oil if you have tight tolerances (i.e. $$ in machining costs) and can ensure oil film thickness. The benefit is reduced pumping power. That's why race cars and OEM cars are going to thinner oils.

However, if you run on the "loose" end of clearances, you need to ensure sufficient oil film thickness to support the loads. That's why older cars run high viscosity oils, and it is easier for the occasional tracker to just dump in some higher viscosity oil instead of adding supplemental oil coolers while on a hot track.

Bottom line for our NSX's:

1) You need to know your oil temperature during normal and "spirited" driving.

2) If you are on the track and notice your oil temperatures increasing much above how Honda designed it, then look at the various data oil manufacturers publish on viscosity at elevated temps and consider switching to a higher viscosity oil. HOWEVER, switch back to 5 or 10W30 afterwards for the street.

Rebuilding an engine with clearances outside of OEM specs, or adding supplemental oil coolers changes everything. You should know what you are doing at that point.

For example, you need to know the following:

1) OEM oil pump and bypass puts out about 16GPM between 6k RPM until redline. It is a positive-displacement gerotor pump, so volumetric flow is determined based on engine speed.

2) The oil pump bypass obviously begins to open at about 6k RPM.

3) VTEC engages at ~5700 RPM and opens up another oil passageway that flows higher volume through the rockers. That's why there is a pressure drop when VTEC engages. Think the oil pump bypass engine RPM and VTEC engagement RPM are coincidental?

4) Keeping all other variables constant (i.e. clearances, operating temperature, etc), switching to a thicker oil or adding an oil cooler downstream of the pump bypasses oil earlier through the relief spring and plunger. This is because the oil pump is "seeing" a higher discharge pressure and will open up the plunger a bit earlier. Pressure (as measured at the heads in the OEM sender location) decreases, and flow volume decreases to the engine. If you do these things, you need to add a shim to the oil pump bypass spring to compensate.

However, shimming the oil pump bypass spring can also be bad. Why does the OEM pump bypass at 6k RPM? That is to reduce the potential for pump cavitation. That is the "magical" sintered metal oil pump gear harmonic that leads to them shattering when on the racetrack at sustained engine speeds. Reducing pump bypass flow to keep up your oil pressure will lead to more pump cavitation.

There is no perfect solution. It is all a major balancing game that the engineers played many years ago. Deviate too far from their input parameter assumptions and you better know what you are doing.

FYI - I'm not an expert, but I'm a physicist that enjoys tinkering. I use a semi-dry sump that utilizes the OEM oil pump with other tanks, but I've completely reworked the pump to optimize it (welded/smoothed passageways and peened gear). Also, I've completely ditched the OEM oil cooler and filter pedestal for a custom setup. BUT, I've rebuilt my engine with specific clearances, and have analyzed the rest of the oil supply system accordingly.

Dual air/oil ~80,000 Btu coolers with staggered thermostats to control the fans, Canton CM-45 filter, 12AN Russell ProFlex hose with their AnoTuff swivel fittings, and Mocal OT2 custom thermostat.

Seems to work OK, but I've yet to track it on a hot day with my ~500 WHP setup.

Dave

The Honda engineers sized our oil pump gerotors, bypass spring, oil filter recommendation, and oil viscosity recommendation based on service temperature (in the service manual), and ultimately the engine bearing clearances and valvetrain requirements (VTEC, etc).

You can go with a "thinner" oil if you have tight tolerances (i.e. $$ in machining costs) and can ensure oil film thickness. The benefit is reduced pumping power. That's why race cars and OEM cars are going to thinner oils.

However, if you run on the "loose" end of clearances, you need to ensure sufficient oil film thickness to support the loads. That's why older cars run high viscosity oils, and it is easier for the occasional tracker to just dump in some higher viscosity oil instead of adding supplemental oil coolers while on a hot track.

Bottom line for our NSX's:

1) You need to know your oil temperature during normal and "spirited" driving.

2) If you are on the track and notice your oil temperatures increasing much above how Honda designed it, then look at the various data oil manufacturers publish on viscosity at elevated temps and consider switching to a higher viscosity oil. HOWEVER, switch back to 5 or 10W30 afterwards for the street.

Rebuilding an engine with clearances outside of OEM specs, or adding supplemental oil coolers changes everything. You should know what you are doing at that point.

For example, you need to know the following:

1) OEM oil pump and bypass puts out about 16GPM between 6k RPM until redline. It is a positive-displacement gerotor pump, so volumetric flow is determined based on engine speed.

2) The oil pump bypass obviously begins to open at about 6k RPM.

3) VTEC engages at ~5700 RPM and opens up another oil passageway that flows higher volume through the rockers. That's why there is a pressure drop when VTEC engages. Think the oil pump bypass engine RPM and VTEC engagement RPM are coincidental?

4) Keeping all other variables constant (i.e. clearances, operating temperature, etc), switching to a thicker oil or adding an oil cooler downstream of the pump bypasses oil earlier through the relief spring and plunger. This is because the oil pump is "seeing" a higher discharge pressure and will open up the plunger a bit earlier. Pressure (as measured at the heads in the OEM sender location) decreases, and flow volume decreases to the engine. If you do these things, you need to add a shim to the oil pump bypass spring to compensate.

However, shimming the oil pump bypass spring can also be bad. Why does the OEM pump bypass at 6k RPM? That is to reduce the potential for pump cavitation. That is the "magical" sintered metal oil pump gear harmonic that leads to them shattering when on the racetrack at sustained engine speeds. Reducing pump bypass flow to keep up your oil pressure will lead to more pump cavitation.

There is no perfect solution. It is all a major balancing game that the engineers played many years ago. Deviate too far from their input parameter assumptions and you better know what you are doing.

FYI - I'm not an expert, but I'm a physicist that enjoys tinkering. I use a semi-dry sump that utilizes the OEM oil pump with other tanks, but I've completely reworked the pump to optimize it (welded/smoothed passageways and peened gear). Also, I've completely ditched the OEM oil cooler and filter pedestal for a custom setup. BUT, I've rebuilt my engine with specific clearances, and have analyzed the rest of the oil supply system accordingly.

Dual air/oil ~80,000 Btu coolers with staggered thermostats to control the fans, Canton CM-45 filter, 12AN Russell ProFlex hose with their AnoTuff swivel fittings, and Mocal OT2 custom thermostat.

Seems to work OK, but I've yet to track it on a hot day with my ~500 WHP setup.

Dave

Similar threads

- Replies

- 9

- Views

- 1K

- Replies

- 51

- Views

- 3K