GOOD CHOICE!----I had a long talk with Racetec's owner at the PRI show last week. I found their seats to fit better than Sparco, OMP, Recaro, Cobra (even though I have been racing with a Cobra "Suzuka" for years), Kirkey, and I sat in ALL of them. Their newest C/F SFI seat costs $ 5700, but their fiberglass version of the same seat is $ 3300----the strange thing is the glass seat is almost 40% STRONGER than the C/F. You pay the extra $ 2400 for 22 lbs. of weight savings, & get a weaker seat! The owner was VERY straight-up & helpful---and I would definitely have bought their seat (right there at the show), IF I hadn't have visited the "fitter" at the Butler-Built display----all I can say is the difference in the way the BB "wrap-around" design feels is amazing. You won't have to wonder though, because of your height, you wouldnt be able to use a "lay-back" design without your feet being all jammed up in the foot box (which is very dangerous besides uncomfortable).

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Down Under Trackday NSX

- Thread starter f1racr

- Start date

Racetech seats are pretty good but they don't do a seat narrow enough.

Narrow enough for what ??

They will make seats to your specifications and they have some very narrow seats in their range, these are extra wide (too many pies) ones for me, so I'm not sure what you mean exactly.

They will make seats to your specifications and they have some very narrow seats in their range, these are extra wide (too many pies) ones for me, so I'm not sure what you mean exactly.

Too funny about the pies!---in my case that would be "Coronas". FYI to all;

The VERY great-fitting RACETECH seat I sat in at the PRI show (their latest generation) fit me SNUG, & it was their wide version! Turns out they consider a 16" seat wide---their "regular" seat is only 15" wide (for all you "racer boys" with 32" waists & under 180lbs). FWIW, I'm 200lbs with a 34-35" waist (depending on what time of the month it is)---ALSO, you can "electric-knife" (trim) the bottom seat cushion if you are on the tall side. I have raced in my COBRA Suzukas for years with the bottom cushion COMPLETELY removed, to mitigate helmet-to-roll cage clearance issues.

BTW, if you're really tall you can use after-market brake & clutch pedal assy's, & mount them HIGHER in the foot box, & build a "sub-floor" in the foot well which positions your heel closer to the "firewall"---good for 1.5"!

The VERY great-fitting RACETECH seat I sat in at the PRI show (their latest generation) fit me SNUG, & it was their wide version! Turns out they consider a 16" seat wide---their "regular" seat is only 15" wide (for all you "racer boys" with 32" waists & under 180lbs). FWIW, I'm 200lbs with a 34-35" waist (depending on what time of the month it is)---ALSO, you can "electric-knife" (trim) the bottom seat cushion if you are on the tall side. I have raced in my COBRA Suzukas for years with the bottom cushion COMPLETELY removed, to mitigate helmet-to-roll cage clearance issues.

BTW, if you're really tall you can use after-market brake & clutch pedal assy's, & mount them HIGHER in the foot box, & build a "sub-floor" in the foot well which positions your heel closer to the "firewall"---good for 1.5"!

Well a little more progress today............ well actually, not sure removing stuff is counted as progress, but you know what I mean !!

Finally got around to cutting the floor out today on the drivers side as we need to put in a new floor to give me the maximum amount of headroom since it's all a bit tight. Took the seat shell that Racetech made and once I'd cut the floor we just mocked up where we expect the new floor to be (flush with main sills) which will be about 1-2cm lower than the factory floor..........seems like a lot of effort, but it shouldn't be too hard and every cm counts as I want to give myself enough space to not only clear the bars, but ideally be far enough away from it in case of a large shunt........ I'll only get so much, but I think it's worth the effort.

Finally got around to cutting the floor out today on the drivers side as we need to put in a new floor to give me the maximum amount of headroom since it's all a bit tight. Took the seat shell that Racetech made and once I'd cut the floor we just mocked up where we expect the new floor to be (flush with main sills) which will be about 1-2cm lower than the factory floor..........seems like a lot of effort, but it shouldn't be too hard and every cm counts as I want to give myself enough space to not only clear the bars, but ideally be far enough away from it in case of a large shunt........ I'll only get so much, but I think it's worth the effort.

Well this is the last update for the year as I'm going to finish work tomorrow and then everything stops.......... I've not had any real holidays during the year as I work for myself so I'm saying sod it to everything and just going to stop for a couple of weeks and recharge. Even though my number one love is cars (after my fiancee in case she's reading LOL) it still can feel like work sometimes to try and keep things moving along so it'll be good to stop for a bit.

Racetech are also suppliers of Lifeline safety systems (from the UK) and so they've organised me a great little bundle of an electronic release - plumbed in fire extinguisher system for the car which will be wired up to emergency buttons which can be used inside the car for me or outside the car by marshalls after they pull the emergency lever in case I'm injured or whatever. Also got a handheld unit for mounting inside the car also in case I see some other poor soul in need on the track and then at least I can stop and help !

Racetech are also suppliers of Lifeline safety systems (from the UK) and so they've organised me a great little bundle of an electronic release - plumbed in fire extinguisher system for the car which will be wired up to emergency buttons which can be used inside the car for me or outside the car by marshalls after they pull the emergency lever in case I'm injured or whatever. Also got a handheld unit for mounting inside the car also in case I see some other poor soul in need on the track and then at least I can stop and help !

Well it's a new year and hopefully we'll be able to progress as well as we did last year. Hopefully by Xmas next year the car will be well finished and my only present would be a great day at the track !!  Still a lot to do.

Still a lot to do.

Got started by stripping down the brakes I purchased as 2 of them looked like they'd been hand painted by a 5 year old and I wanted them all the same colour anyhow so needed to paint 2, so figured I'd strip them all and paint them again once I'd stripped them back.

Well needless to say, it was a whole load more awkward and time consuming than I'd given it credit for even with a sand blaster .........

There was a whole load of coats on the red Brembo F50's as they look like they'd been painted a couple of times over the top of the original finish and then there was the base coatings which I guess is some form of powdercoating. You'll see from the pics that I didn't get them 100% clean, but the area's where it shows some paint it's very smooth so won't cause issues with the repaint and I've also still got some finishing work to do with the dremel to get the little niggly bits, but most aren't going to cause any issues.

I've got some special VHT paint which is 3 layers (base, colour and clear) and says it will handle up to 900 degrees so I'm going to give that a try and see how it goes....... might be a waste of time, but VHT products seem to be pretty good so fingers crossed !!

I've stripped all of the seals, pistons and other parts from the brakes as we're going to purchase some new seals, dust covers and other bits to rebuild them and make sure they're tip top before I put them on.

I'll post more pics of progress as I get started recoating them.

In other news ..... I've managed to find a place to locate the car closer to home which is awesome and I'm just waiting to sign the lease and we can move the car down to the new workshop and get onto finishing the rollcage and making the seat mountings so I can get the new floor welded in. I've got my new pedals from Tilton on the way also so we'll need to get those mounted when they arrive as well as make the new steering column........

Got started by stripping down the brakes I purchased as 2 of them looked like they'd been hand painted by a 5 year old and I wanted them all the same colour anyhow so needed to paint 2, so figured I'd strip them all and paint them again once I'd stripped them back.

Well needless to say, it was a whole load more awkward and time consuming than I'd given it credit for even with a sand blaster .........

There was a whole load of coats on the red Brembo F50's as they look like they'd been painted a couple of times over the top of the original finish and then there was the base coatings which I guess is some form of powdercoating. You'll see from the pics that I didn't get them 100% clean, but the area's where it shows some paint it's very smooth so won't cause issues with the repaint and I've also still got some finishing work to do with the dremel to get the little niggly bits, but most aren't going to cause any issues.

I've got some special VHT paint which is 3 layers (base, colour and clear) and says it will handle up to 900 degrees so I'm going to give that a try and see how it goes....... might be a waste of time, but VHT products seem to be pretty good so fingers crossed !!

I've stripped all of the seals, pistons and other parts from the brakes as we're going to purchase some new seals, dust covers and other bits to rebuild them and make sure they're tip top before I put them on.

I'll post more pics of progress as I get started recoating them.

In other news ..... I've managed to find a place to locate the car closer to home which is awesome and I'm just waiting to sign the lease and we can move the car down to the new workshop and get onto finishing the rollcage and making the seat mountings so I can get the new floor welded in. I've got my new pedals from Tilton on the way also so we'll need to get those mounted when they arrive as well as make the new steering column........

good to see you back at it Fraser, was starting to miss your updates !

Are they what are referred to as "brembo lotus" calipers?

Are they what are referred to as "brembo lotus" calipers?

Last edited:

Well it's been a couple of long days at the electronic coalface (I work in I.T) but I've made time last night and this morning to get all of the piston holes and other threads all masked out so that I could paint them with a couple of coats of the base coat from VHT. My god what a time consuming mission it was to mask off around those seals...... seemed like a good idea to repaint these at the time !! LOL

Got chance to spray that on and let it set for it's official 3 hours and then I just used a bit of 1200 grade wet and dry sand paper to take out any high spots I could see and dryed again before just dusting over the first coat of the colour.......... will give it another coating tomorrow with some more sanding to try and get as nice a finish as possible and then I've got to put some clear on to finish them all off and then sand again.........

Got chance to spray that on and let it set for it's official 3 hours and then I just used a bit of 1200 grade wet and dry sand paper to take out any high spots I could see and dryed again before just dusting over the first coat of the colour.......... will give it another coating tomorrow with some more sanding to try and get as nice a finish as possible and then I've got to put some clear on to finish them all off and then sand again.........

Last edited:

Hi guys,

Sorry there hasn't been many updates recently, but finding a new home for the NSX has been a bit harder than expected, but I've got somewhere now and we'll hopefully move the car on Friday so next week we'll be able to get started and we plan on having a "blokes weekend" soon too, to really get some of the stuff finished like the front of the cage and other bits and then it's ready to get the new floor welded in and then we're getting close to getting all the carbon fibre interior and bits started !! Can't wait.

In the meantime I've got some more updates on the new brakes. I've been waiting on the Brembo masks to show up so I could finally get them painted...... so here's the pics....... they've come out really well I think and I've just got to put a couple of coats of clear on each one and they're ready to be rebuilt and put on the car.

My new wheels will be here soon I hope so we can get them fitted also, as once we've got these brakes on the car the factory wheels won't fit anymore.

Sorry there hasn't been many updates recently, but finding a new home for the NSX has been a bit harder than expected, but I've got somewhere now and we'll hopefully move the car on Friday so next week we'll be able to get started and we plan on having a "blokes weekend" soon too, to really get some of the stuff finished like the front of the cage and other bits and then it's ready to get the new floor welded in and then we're getting close to getting all the carbon fibre interior and bits started !! Can't wait.

In the meantime I've got some more updates on the new brakes. I've been waiting on the Brembo masks to show up so I could finally get them painted...... so here's the pics....... they've come out really well I think and I've just got to put a couple of coats of clear on each one and they're ready to be rebuilt and put on the car.

My new wheels will be here soon I hope so we can get them fitted also, as once we've got these brakes on the car the factory wheels won't fit anymore.

very professional look. But you didn't answer my question ... are they "brembo lotus" calipers ?

Oh sorry mate missed that part of your post.

No they're not Lotus calipers, these are Brembo F50 calipers, well the fronts are and the rears I thought were the same, but they're just very close and have the same mountings and parts etc, but are from a 2007 Dodge Viper... !! Well actually it's the other way around. Pics are of Dodge ones, but the other 2 (will post pics later) are Ferrari F50.

Pistons might end up being too big for the rear, but I've spent plenty of time on the phone with Tilton and we think the numbers work out.

Ideally I'm hoping to only use this setup for a little while and then I'd like to get the Performance Friction full setup as it looks the dogs danglies as far as I'm concerned, but the money is better spent elsewhere at the moment for me if I can get these to work OK for setup and basic running and then once I know all is well I'll start saving for the others and sell this setup as a known good combo.

No they're not Lotus calipers, these are Brembo F50 calipers, well the fronts are and the rears I thought were the same, but they're just very close and have the same mountings and parts etc, but are from a 2007 Dodge Viper... !! Well actually it's the other way around. Pics are of Dodge ones, but the other 2 (will post pics later) are Ferrari F50.

Pistons might end up being too big for the rear, but I've spent plenty of time on the phone with Tilton and we think the numbers work out.

Ideally I'm hoping to only use this setup for a little while and then I'd like to get the Performance Friction full setup as it looks the dogs danglies as far as I'm concerned, but the money is better spent elsewhere at the moment for me if I can get these to work OK for setup and basic running and then once I know all is well I'll start saving for the others and sell this setup as a known good combo.

Last edited:

Viper and F50 ! you're choosing from some mean machines there. I must have a look at performance friction, but I've learnt from experience it's tempting to fit bigger brakes than what's actually needed. In you case where the car is probably only going to be between 1100 - 1200 kg I'd be looking for modest sized brakes with good pedigree, rather than huge. For example my 2002 Boxster S had the stock 328 x 28 x-drilled rotors on a car weighing around 1300kg, and those brakes (porsche use brembo calipers) would do 50 laps flat out on a tough braking circuit no fade whatsoever. One of the secrets is the superior design of the brembos with different sized pistons to balance the pad on the rotor under force, and the quality of the porsche rotors. Of course the big win from modest sized brakes is lower unsprung weight = tyre follows road better.

Sorry I'm probably telling you how to suck eggs, but it's one of my hobby horses

Sorry I'm probably telling you how to suck eggs, but it's one of my hobby horses

Last edited:

Yeah don't fear, I've got a fair amount of knowledge on the brake front and I feel it's the most important part of the car along with the suspension...... you've got to feel confident when you're doing well over 200kph into corners and need to slow down and the brakes and suspension are going to give you that confidence so if it's not good I'll just have to find a way to get the PF kit earlier, but I'm sure we can make these go OK.

As mentioned, I've chatted with Tilton quite a bit to make sure we get a good pedal and master cylinder combo and I've got a good race brake supplier here also who's going to help with pad compounds so we can find a good balance.

As mentioned, I've chatted with Tilton quite a bit to make sure we get a good pedal and master cylinder combo and I've got a good race brake supplier here also who's going to help with pad compounds so we can find a good balance.

So I promise this will be the last brake picture for a while till I get them on the car

I had a bit of a disaster yesterday when I was painting the final 2 coats of high temp clear........ they were all painted and looking great....... better than I'd hoped and so I left them outside to dry in the hot sun for a few hours when an hour later I heard some very heavy metal objects hit concrete....... !!!!

Yep you guessed it, the metal corded line I had hung them on to paint had snapped and they were all on the ground !! luckily for me because of the way I'd hung them they fell onto their bottoms and they had taken paint off back to the base, but not too bad and so I had to sand back those area's and repaint the red and clear in those area's even though no one will see them, I wanted them to be perfect.

luckily for me because of the way I'd hung them they fell onto their bottoms and they had taken paint off back to the base, but not too bad and so I had to sand back those area's and repaint the red and clear in those area's even though no one will see them, I wanted them to be perfect.

After all painting was done, I baked them as per the instructions for 1 hour at 230F

I had a bit of a disaster yesterday when I was painting the final 2 coats of high temp clear........ they were all painted and looking great....... better than I'd hoped and so I left them outside to dry in the hot sun for a few hours when an hour later I heard some very heavy metal objects hit concrete....... !!!!

Yep you guessed it, the metal corded line I had hung them on to paint had snapped and they were all on the ground !!

After all painting was done, I baked them as per the instructions for 1 hour at 230F

Last edited:

So the new workshop is still a bloody tip, but we're getting there and I had an e-mail from the guys from SSR to say my new wheels are made, but they've just realised that they didn't get measurements for my brakes !

So I've had to mock up the new calipers and rotors in place to measure up about 15 different measurements for them before they ship them, but if everything works out OK it means they'll leave on Wednesday and will take about 3 weeks to get here after 3 months of waiting for them to be made, I bloody hope it's all good !

They said the rears have a 95mm dish

Cooooool I think they're going to look awesome.

Cooooool I think they're going to look awesome.

So I've got some average pics as I didn't have my proper camera with me so it's just from my phone, but gives you a rough idea of what we've got...... will take some more when it's not raining.

This picture gives you a good idea of the new rotors vs the factory wheels !!

And now compared to the old rotor on top...... !!!

All mounted........ look awesome I think !

Mock up using base of new bonnet.

Hopefully tomorrow we're going to get some more roll cage tubing and then on the weekend we'll be getting into getting the rest of the cage finished and some other little bits and pieces sorted and it'll start really moving along again....... all gone a bit slow for the last few months for my liking !!

So I've had to mock up the new calipers and rotors in place to measure up about 15 different measurements for them before they ship them, but if everything works out OK it means they'll leave on Wednesday and will take about 3 weeks to get here after 3 months of waiting for them to be made, I bloody hope it's all good !

They said the rears have a 95mm dish

So I've got some average pics as I didn't have my proper camera with me so it's just from my phone, but gives you a rough idea of what we've got...... will take some more when it's not raining.

This picture gives you a good idea of the new rotors vs the factory wheels !!

And now compared to the old rotor on top...... !!!

All mounted........ look awesome I think !

Mock up using base of new bonnet.

Hopefully tomorrow we're going to get some more roll cage tubing and then on the weekend we'll be getting into getting the rest of the cage finished and some other little bits and pieces sorted and it'll start really moving along again....... all gone a bit slow for the last few months for my liking !!

Well as is the case with life, today was good but mostly bad. Had a bit of a disaster with SSR. After waiting 2.5 months for the wheels to be made SSR have realised that they won't fit over my brakes !!!  Gutted !

Gutted !

Luckily I don't have to pay for the ones they've made as they didn't check initially and said it would easily clear the brakes, but it's not even close !

So it's back to the drawing board and is a real setback if we have to wait all that time again for SSR to make something else or some other brand........... we're just looking at options now to see what I can get that will fit.

Got the workshop nearly ready which is awesome. Steve's been working hard and nearly sent himself to the E.R a couple of times with cuts !!!

Luckily I don't have to pay for the ones they've made as they didn't check initially and said it would easily clear the brakes, but it's not even close !

So it's back to the drawing board and is a real setback if we have to wait all that time again for SSR to make something else or some other brand........... we're just looking at options now to see what I can get that will fit.

Got the workshop nearly ready which is awesome. Steve's been working hard and nearly sent himself to the E.R a couple of times with cuts !!!

Last edited:

Thats a real bummer ... mind you those brake discs look huge. What size are the SSR wheels (and by the way, who are SSR ?)

SSR is the wheel division of Tanabe.

http://www.ssr-wheels.com/ Quite famous Japanese wheel maker, been around for a long time and have created a lot of the innovations in wheel making over the years........

The wheels we had planned were

8.5x18" front with +0 offset

10.5x18" rear with +12 offset

Just not the best shape inside the wheel and so will clip the outside of the calipers

Still, there's other designs out there from other people so we'll see......

http://www.ssr-wheels.com/ Quite famous Japanese wheel maker, been around for a long time and have created a lot of the innovations in wheel making over the years........

The wheels we had planned were

8.5x18" front with +0 offset

10.5x18" rear with +12 offset

Just not the best shape inside the wheel and so will clip the outside of the calipers

Still, there's other designs out there from other people so we'll see......

Yeah, most of the stuff I've sourced for the car has come from your side of the world........ I'd have been nowhere with parts if it wasn't for Ross from STMPO, the guys at FXMD and Titanium Dave....... oh and a couple of other Prime members !!

In other news. Just to make sure we weren't going mad regarding the brake clearance we took one of the Work CR KAI wheels off my Civic which are 18x8.5 the same as I need for NSX, but are +35 offset to see if there was enough inside clearance to get over 355mm rotors and calipers and it's tight, but they cleared so I'm going to go back to SSR and find out why theirs are supposedly so far out !

In other news. Just to make sure we weren't going mad regarding the brake clearance we took one of the Work CR KAI wheels off my Civic which are 18x8.5 the same as I need for NSX, but are +35 offset to see if there was enough inside clearance to get over 355mm rotors and calipers and it's tight, but they cleared so I'm going to go back to SSR and find out why theirs are supposedly so far out !

Yeah it's been a bit of a hassle, but I'm sure we'll figure it out soon enough and get things back under way.....needless to say I'll post here once we've got a solution !

Well still no news from SSR about what's happening with the wheels, but I have pushed them, but they say they're still looking into it, so no idea if I'll have to change or not yet........ soon hopefully I'll have an answer.

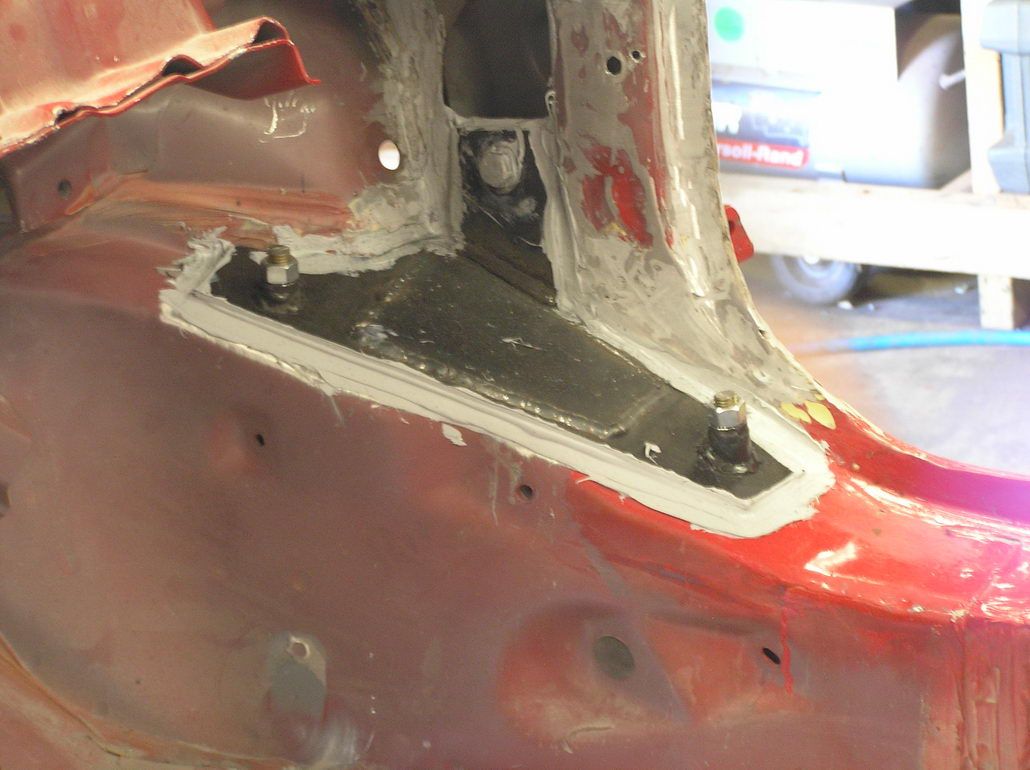

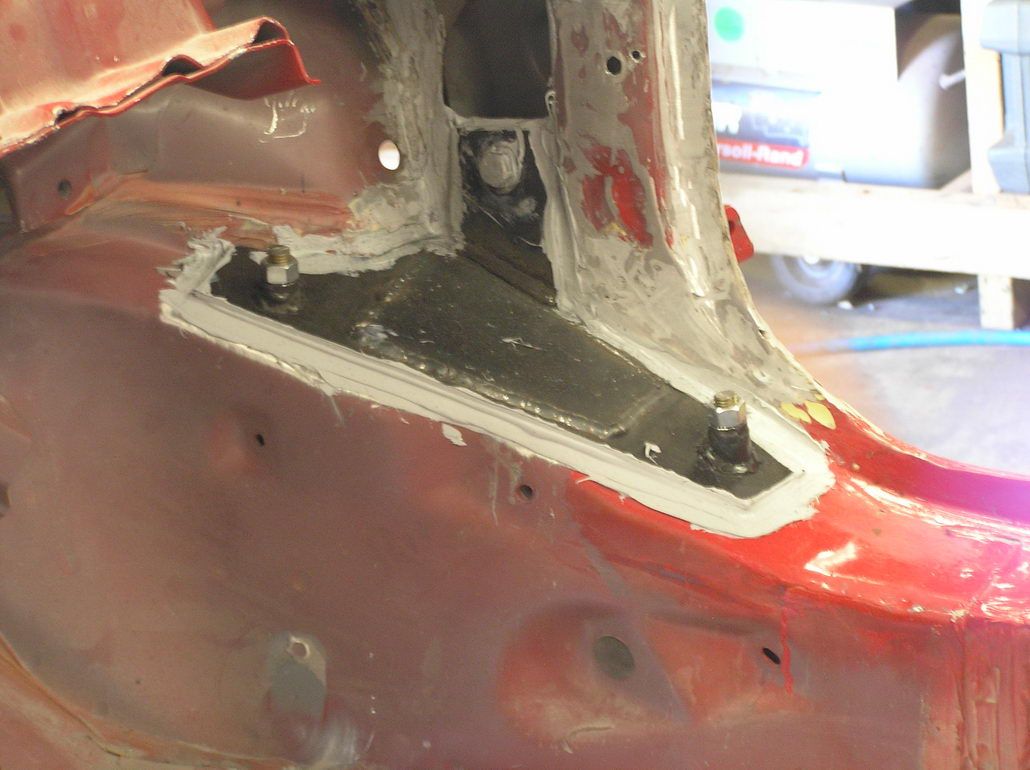

In other news, we've been working very hard (both Steve from Frost Motorsport and myself) to get the front footplates made, some rather long holes drilled through all the skins of the main chassis rails so we can bolt them in right through the shell of the car, making the mounting brackets for the headlights (what a bloody mission)......... and then remaking them as I realised I'd mounted them too far back !! Doh !

So today, about 2 weeks of hard work came together and we finally got the front footplates bolted and bonded in place which is awesome as its another major milestone to getting the front of the cage finished. We've mapped out the plan for the rest of the bars and now it's really up to Steve to get the bars bent as I can't really help there, but I'll be doing what I can to make life easier for him.

We're also going to extend the cage into the cage to have bars for the seats to mount on so that the seats are physically attached to the cage......

In other news, we've been working very hard (both Steve from Frost Motorsport and myself) to get the front footplates made, some rather long holes drilled through all the skins of the main chassis rails so we can bolt them in right through the shell of the car, making the mounting brackets for the headlights (what a bloody mission)......... and then remaking them as I realised I'd mounted them too far back !! Doh !

So today, about 2 weeks of hard work came together and we finally got the front footplates bolted and bonded in place which is awesome as its another major milestone to getting the front of the cage finished. We've mapped out the plan for the rest of the bars and now it's really up to Steve to get the bars bent as I can't really help there, but I'll be doing what I can to make life easier for him.

We're also going to extend the cage into the cage to have bars for the seats to mount on so that the seats are physically attached to the cage......

Similar threads

- Replies

- 0

- Views

- 206

- Replies

- 1

- Views

- 287