Little bit of progress today......... got a new toy as well which has already done a good job cleaning the intake plenum from Steves R33 GTR.

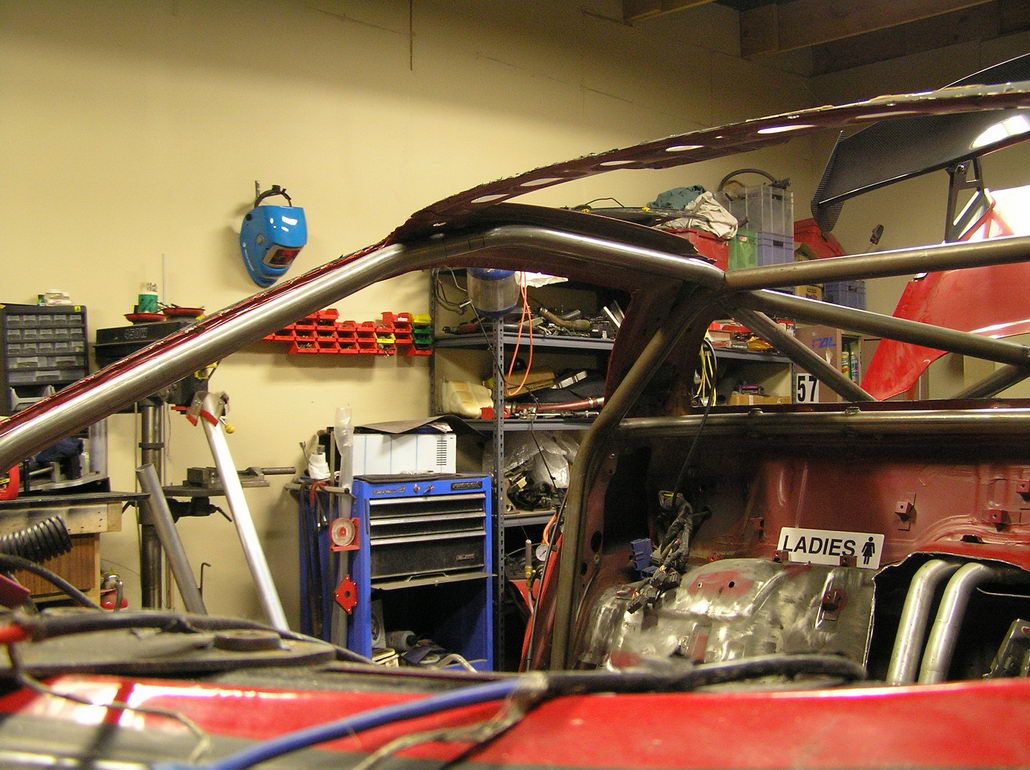

Also we got started on the cage extensions which will support the seat mounting and also Steve's been doing some thinking as well and we'll be able to tie this all into the front of the cage too so overally it will help strengthen things also which supporting the seats properly too.

This is a rough diagram (yes very rough) of what we're aiming to do in the couple of weeks.

The orange parts shown are some mountings that will be bolted to the floor of the car so the tube from the back part of the car has somewhere to mount to. The bars will continue along to the front of the car and will tie into the front of the cage as well.

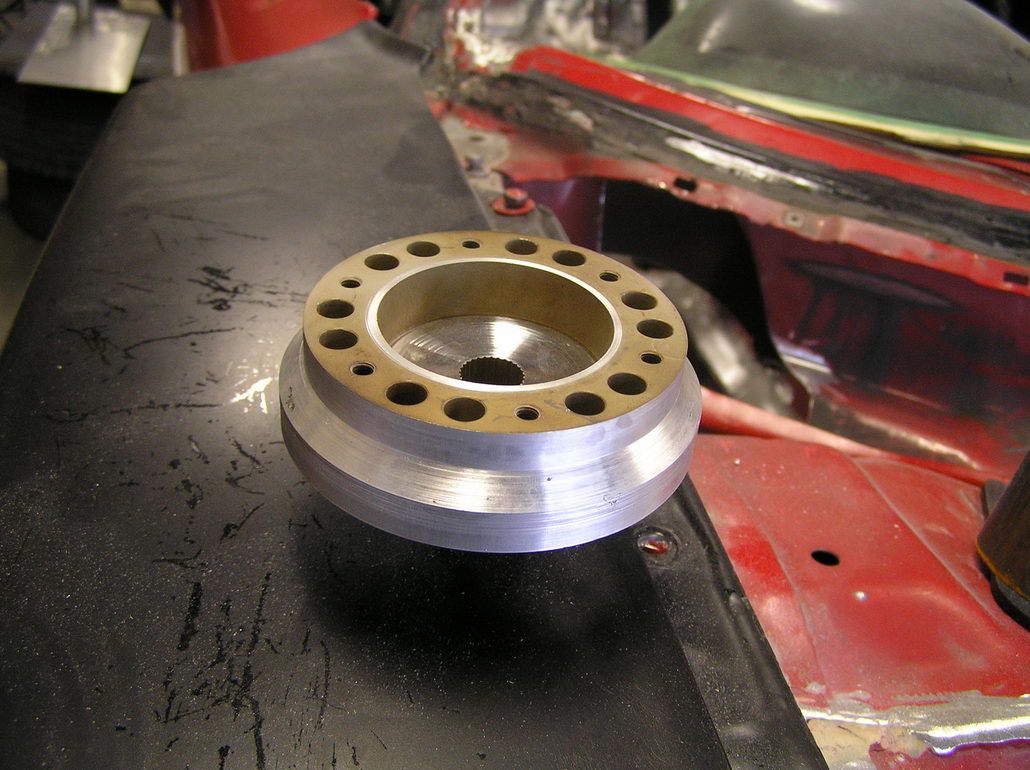

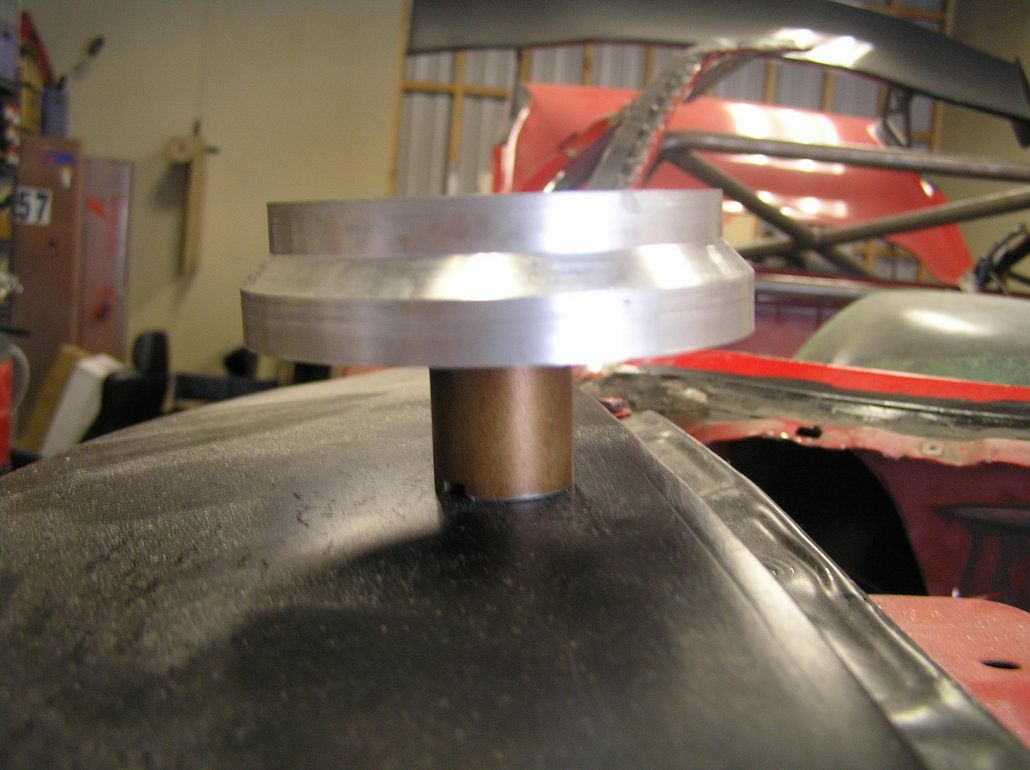

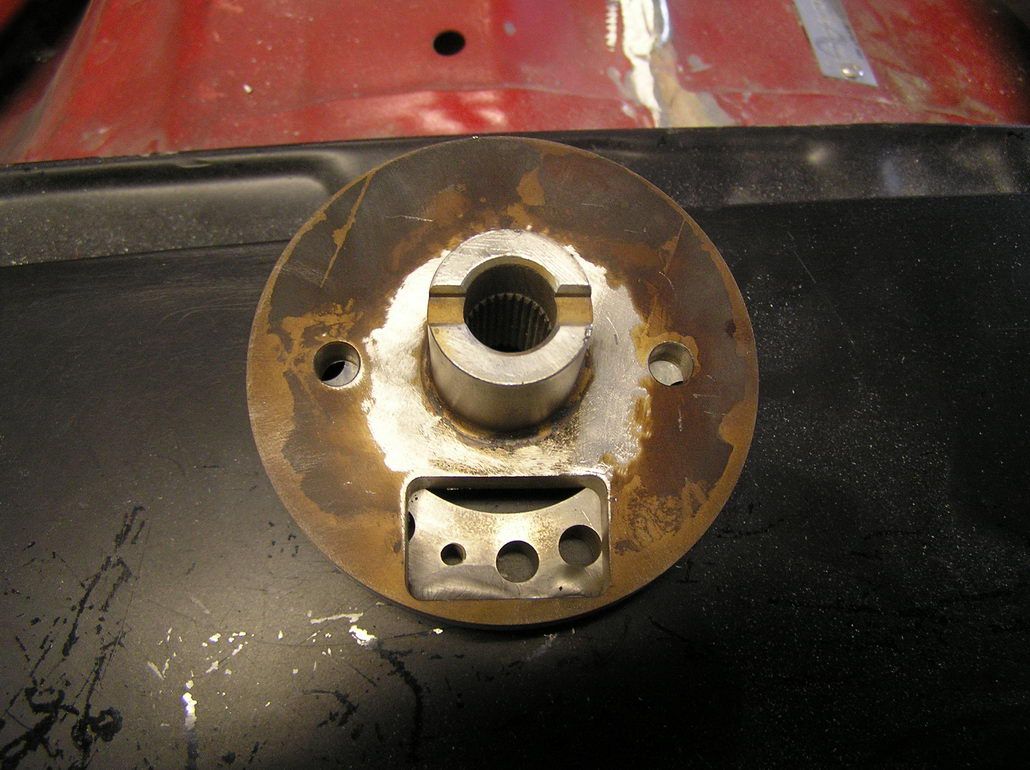

I also started on the mounting of the reserviors for the suspension too

Also we got started on the cage extensions which will support the seat mounting and also Steve's been doing some thinking as well and we'll be able to tie this all into the front of the cage too so overally it will help strengthen things also which supporting the seats properly too.

This is a rough diagram (yes very rough) of what we're aiming to do in the couple of weeks.

The orange parts shown are some mountings that will be bolted to the floor of the car so the tube from the back part of the car has somewhere to mount to. The bars will continue along to the front of the car and will tie into the front of the cage as well.

I also started on the mounting of the reserviors for the suspension too