My first NSX ('91 silver) wasn't in the snap ring range but my current red '92 is. I bought it knowing the fact and accounted for that during the purchase. I've known an NSX at my local dealer for the last 15 years who's a personal friend of mine as well. He's inspected and replaced many transmission cases on affected cars. I had him check mine and going in through the inspection port, he was able to feel the lateral play the snap ring had. Mine had very little play and said I lucked out as he's checked play in many others that had much more and some of those wound up failing in the end later on. There is no guarantee but in his opinion I have an excellent chance of not experiencing this dreaded failure. I have close to 30K miles on the car currently. This goes right in what I have heard from many experienced NSX technicians that NOT ALL transmissions are prone to failure just because they are in the range. The snap ring groove varies in width during the manufacturing process so those with grooves cut too wide while will suffer failures. The ones with the widest cuts suffered them early on. There are some snap rings that will break due to wear and tear and I've read about several being those with very high miles.

Here's what I've learned from others about when the snap ring fails:

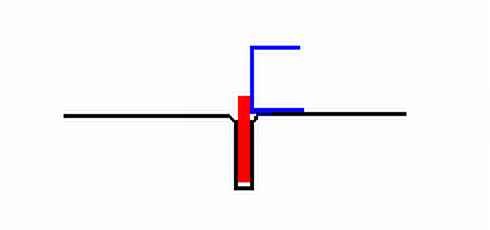

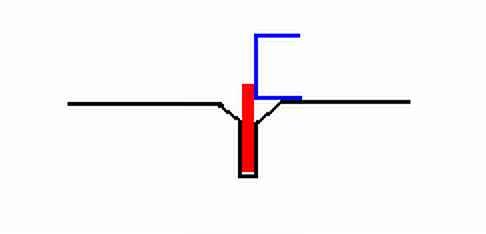

The giveaway for snap ring failure is the shifter moving fore and aft in first or second on deceleration or acceleration from slow speed. This happens because when the snap ring breaks (which holds the countershaft top bearing into the case) the whole countershaft moves back and forth in the case when the direction of load / torque changes. Since first and second selector are on the countershaft, and the selector hub hooks into the selector fork which hooks into the shifters. Most will experience a loud crunch or mechanical grinding sound as the shattered fragments of the broken snap ring grind around in the transmission. The sooner you stop driving while first noticing these symptoms, the less possible internal damage will be done.

Finally…

Mark Basch (perhaps the most experienced and knowledgeable NSX mechanic in the country) posted the following information about the snap ring failure on the NSX e-mail list. Bottom line as I see it from his write-up is this: (1) the preventive repair is often done wrong; (2) unless you’re opening up the tranny anyway, don’t bother with a preventive repair; (3) if your car is in the snap ring range and you DO experience any snap ring symptoms, don’t keep driving it, take it ASAP to a repair place and get it fixed, and it won’t cost any more than the preventive would have.

Here’s the write-up:

--------------

SNAP RINGS — THE FINAL (WE HOPE) CHAPTER.

I can't believe I am still getting these phone calls and emails. I had another one on Friday from an out of state customer who had his snap ring replaced, the third such call in a month. Not the upper tranny case, just the snap ring. This person was sold a snap ring replacement just because he was in range. He had no problem, just that it was in range. But the terrible thing here, IMO, is that he did not get a new case. He was told the snap ring was made of brittle metal and that the new ones are not. This is pure, unadulterated BS. Let me explain one more time, what the issue is here. This info was explained to me very clearly on several occasions, by several different Acura Factory employees, and one very smart AHM employee who is responsible for everything technical/service related, about the NSX. For the purpose of this writing, unless I say "IMO", it is pure fact. Also for the purpose of this writing, the word "tool" refers to a cutting "bit" used in a lathe or mill. Snap Ring Failure is referred to as „SRF".

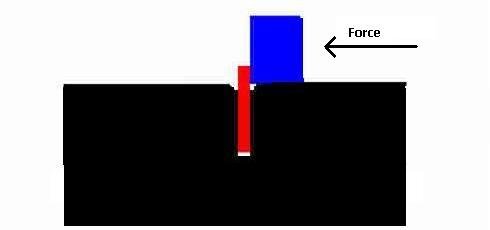

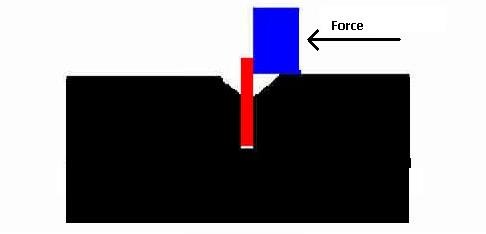

First, the actual failure: The snap ring in question here is the one that holds the top countershaft top bearing in the upper section of the tranny case. It keeps the countershaft from moving under load changes, i.e. on/off the throttle. Without this snap ring, the shaft has approx. 6 or 7mm's of movement. The snap ring fits into a groove machined into the very end of the upper tranny case. This groove is meant to have no more than .01 or .02 mm's clearance around the snap ring. (Note: there is no spec for this clearance available- that number is based on measurements I have taken with new case - new ring). The clearance serves no purpose in the operation of the tranny, as there is no movement here during normal use. The clearance is needed to aid assembly- if it were any tighter, assembly would be difficult / impossible.

The actual cause of SRF: The snap ring groove in some cases, as described in the "affected vehicles" section of the service bulletin that describes this problem, was improperly cut. The groove that holds the snap ring is actually cut with two angles. The groove itself, and a small chamfer that is there to aid in assembly. Without this chamfer, it would be almost impossible for the snap ring to enter the groove. In order to cut these two angles, two "tools" were bolted together to cut the two angles with one pass. If you make a fist, and fully extend your middle and pointer fingers, you will see exactly what these two tools look like bolted together. (The actual size is much smaller- the groove is about 1 mm wide and two mm's deep. The chamfer is about .3 mm's wide. In the "bad" cases, the relative position of the two tools was not constant, and the actual groove was cut too deep by the chamfer tool. With the groove too big, the snap ring was not fully supported, and therefore under heavy loads, the snap ring would actually shatter because it was not fully supported. IOW, since the snap ring only had the case in contact a fraction of its circumference, the (heavy) loads were distributed across a small portion of its surface, rather than fully supported. THIS is what causes the snap ring to fail.

Most important part: Why some affected case's fail, and some don't. IMO, the most important question is why some case's in the range fail and some don't. To understand this, you have to understand two things. First of all, the fix in production for this problem was to make the tool one piece instead of two. That eliminates the possibility of moving tools. (duh!) Second, is the basic practice of all machinist's and operators of automated mills and lathes, to spot check piece's as they are completed to make sure the tools are aligned properly. This spot check is performed every "X" number of finished case's. The actual number is unknown (to me), but for the purpose of this paper, we will use the number 25. It is probably a decent "guess" based on what we have seen, but IT IS only a guess. The actual number is irrelevant for the purpose of understanding what has happened here. So, we have a machine operator who is watching this automated cutting machine make the grooves and chamfers in the NSX transmission cases he is making that day. Every 25 cases he stops the machine and grabs the last case it made and measures the grooves and chamfers he just made, and compares these measurements to design spec. When he realizes that it is too big, he adjusts the tool accordingly, and resumes making cases. After 25 more cases, he does this again, and so on. If you are wondering, as I was when this was explained to me, why the cases were used knowing these grooves were too big, it is probably because it was not known how big was too big, until the snap rings started to fail. This is when the tool was switched to a one-piece tool.

SO - now you have 100 case's made in any given run. Case number one is perfect. If you assume that the shifting of the tools happened in an even speed, then case number two was 1/25th of the total oversize, too big. Case number three was 2/25ths too big, case number four was 3/25ths too big, and so on. By the time case number 25 was checked, it is the worst of the batch (these are probably the ones that failed at 2-3000 miles). Now the tool is adjusted, so case number 26 is PERFECT. Case number 27 is as bad as case number two; case number 28 is as bad as case number three, and so on. So out of 100 case's, 4 are perfect. 4 are perfect less 1/25th of the total oversize, 4 are 2/25ths of the total oversize, and so on. This is the reason you have such an odd pattern of failures. This is why there are cars that have 90k miles and no failure despite being in range (case number one, 26, 51, 76, etc) and cars that failed with 2 or 3 thousand miles on them (case's numbers 25, 50, 75, etc).

The snap ring material has never changed, they are made exactly the same way and from the same material today as 10 years ago. It is one of Honda's most ironclad rules that if a part is changed, even the least detail, it gets a new part number. If this change is made to address a failure problem, it gets a certain part number pre-fix, such as 06154. Without this changed number, it would be impossible to determine if a car was repaired with old or new part, therefore leading to multiple, and unnecessary repairs. i.e.- an NSX tranny has SRF and is repaired. Two years later the FTC rules that Honda must fix all NSX trannies with the potential to fail (wouldn't that be nice). IF they had a problem with the actual snap rings (which they didn't) and IF they had installed improved snap rings with the old number (which they hadn't), then they would have no way to know which car got improved parts and which didn't. Dates alone will not tell them this as dealers could have made a repair with parts out of stock, as opposed to spec order parts. Remember, when it comes to numbers, a system is either ABSOLUTE, or it is no system at all. Changing a part number for improved parts is the ONLY way to track which cars are updated and which are not and I suspect that recalls and other campaigns is the main reason for this ironclad rule.

Bottom line, a transmission that gets a new snap ring, installed in an old case, is the exact same tranny it was before, and just as likely to fail. A snap ring and case costs no more to replace after a failure as it does before unless you drive a long time that way. Additional damage is not automatic. I wish I could give a number of miles you can drive before causing more damage, but I can't. I can tell you I have taken apart trannies where the customer reports he drove it with the obvious signs of SRF for 300 or 400 miles, and there was no extra parts needed. I do not recommend replacing the case before a failure, unless you have the tranny apart anyway i.e. synchro replacement or short gear install. Definitely do it at this time, if you are in range. You may save the money on the case initially, but if you have to overhaul it twice the only person who comes out ahead is the person charging you labor twice. I hope I have not caused more questions than I have answered. If I have for you, please e-mail me for an explanation.

Happy Motoring,

Mark Basch

--------------

Vytas