This is phase two of the power steering rack rebuild. Here is a follow up from part one to get everyone caught up. Valhalla sent me his power steering rack all the way from California to Mississippi because we have become friends and he trusts me after seeing us work on my rack.

I will list pictures and show progress of the repairs in this thread. Part 3 will be Valhalla's reinstallation and his opinions about our service.

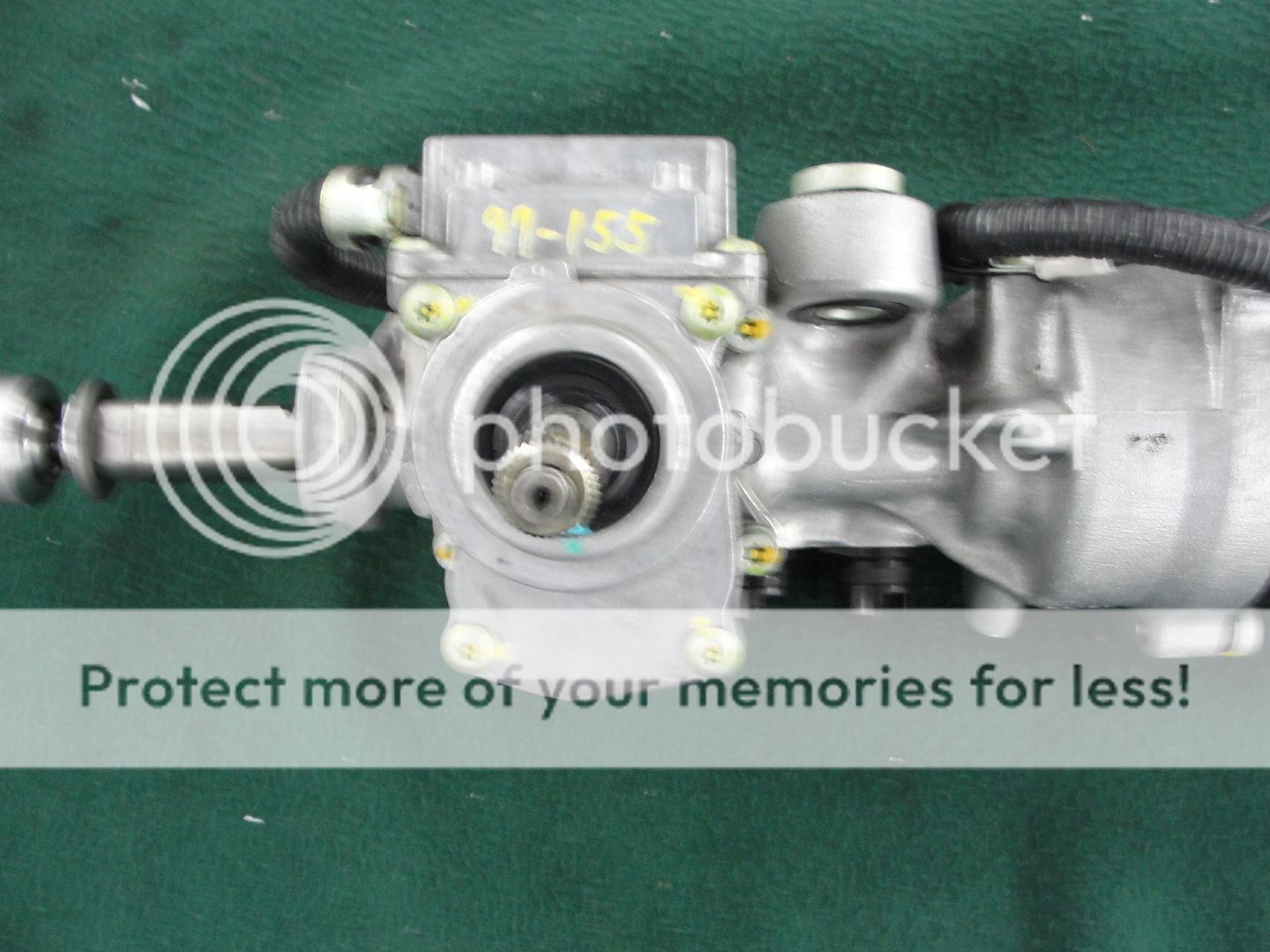

After a good cleaning....looks like were ready to get started. Thanks Valhalla for trusting me with this. I wont let you down.

before the cleaning

After (yes, I realized that I looked like I was getting into the Christmas spirit early....fixed)

Here we go

:biggrin:

:biggrin:

I will list pictures and show progress of the repairs in this thread. Part 3 will be Valhalla's reinstallation and his opinions about our service.

After a good cleaning....looks like were ready to get started. Thanks Valhalla for trusting me with this. I wont let you down.

before the cleaning

After (yes, I realized that I looked like I was getting into the Christmas spirit early....fixed)

Here we go