Why does it need to be so complicated ?

I would think that two Y fittings would do?

In all honesty, I agree with you. We are looking into a different way to do the lines. The way it is now I have no room left for the air ducting from the radiator to the hood, as this system takes up a lot of space.

- - - Updated - - -

It's been quite a long time since my last update... and a lot has happened.

First, we had the car on the dyno. We settled at 385hp @ 400nm after three hours on the dyno. It got quite hot, under normal temperatures the engine will probably delivery just over 400hp.

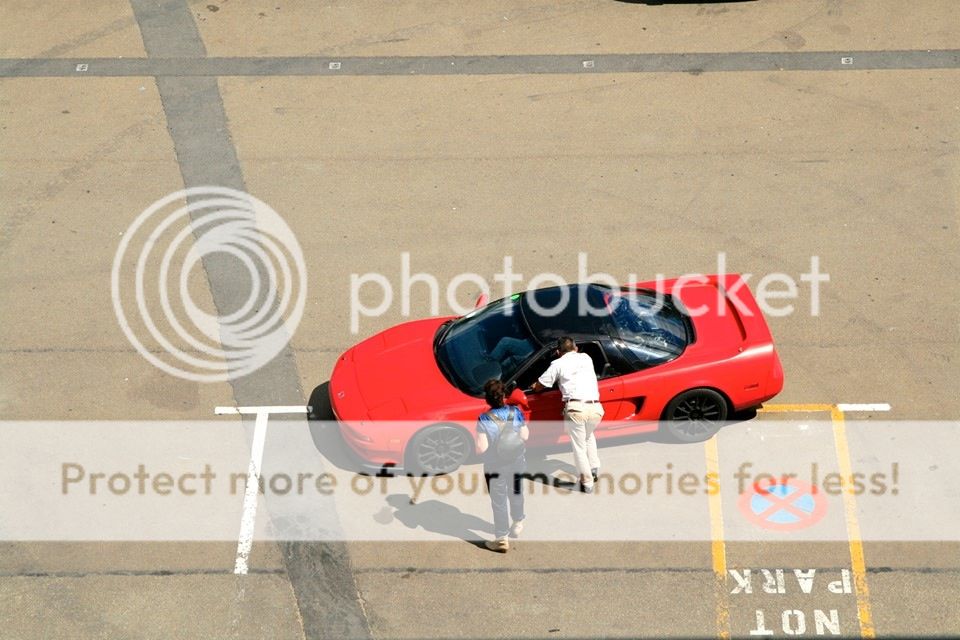

After the car was tuned properly it was time to make some pics:

Honda NSX

Honda NSX by

dimervansanten, on Flickr

Honda NSX

Honda NSX by

dimervansanten, on Flickr

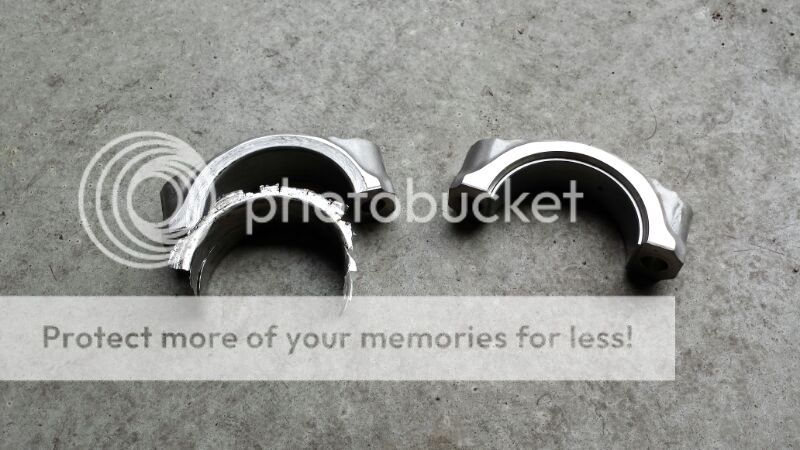

Unfortunately just after the shoot and only 50km after the tune (and 200km after the rebuild) disaster struck.. We heard a weird noise coming from the engine. A kind of rattling/tapping noise. Luckily we were very close to our garage so we headed back. After inspection with a stethoscope and lots of talk with experts we suspected it might be head related. But we couldn't find anything.. Cody advised us to get the car on a lift and take off the oil pan. This is what we found:

That sucked! Especially since this happened just before we would go to Le Mans to test the car on the track. We didn't want this to f*ck up our weekend, so we went anyway.

NSX Club Europe Le Mans 2013

NSX Club Europe Le Mans 2013 by

dimervansanten, on Flickr

NSX Club Europe Le Mans 2013

NSX Club Europe Le Mans 2013 by

dimervansanten, on Flickr

NSX Club Europe Le Mans 2013

NSX Club Europe Le Mans 2013 by

dimervansanten, on Flickr

NSX Club Europe Le Mans 2013

NSX Club Europe Le Mans 2013 by

dimervansanten, on Flickr

NSX Club Europe Le Mans 2013

NSX Club Europe Le Mans 2013 by

dimervansanten, on Flickr

NSX Club Europe Le Mans 2013

NSX Club Europe Le Mans 2013 by

dimervansanten, on Flickr

Luckily we also brought my dad's NSX, so I could do some laps in his car.

Through AS-Motorsport we have located a new engine. We will most probably swap the engines this week. This way we can still be ready for the next race while we can send the other engine to the engine builder to have it examined and fixed.

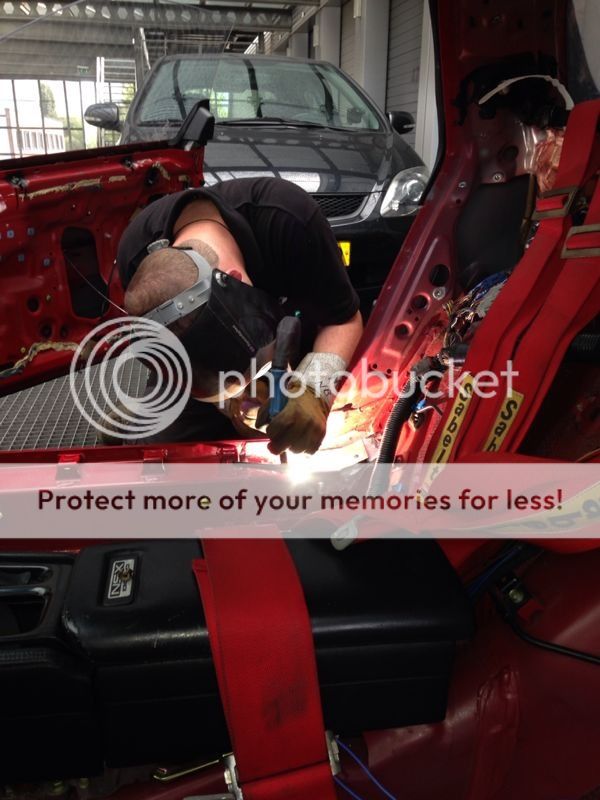

In the meanwhile we finally got the rollcage plates welded, a BIG thank you to Bas (R-Developments). We now have the cage fitted!

Also thanks to Bas (R-Developments) I got a new helmet: