Wow, very old thread....

Any way, it’s not just the mileage that makes the classic LMA tired/sticky but also the time the engine is sitting without running.

You will notice much more spring rate imbalance between each LMA on the low annual mileage NSX than the regularly driven one.

This is because when you stop the engine, some of the valves are kept open.

This means that some of the LMA is also compressed.

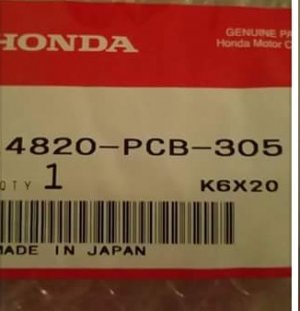

[Latest design LMA for pre-LEV engine at the top, Classic LMA at the bottom (this one is the 2nd gen, looks similar to the 1st gen but bit better against the sticking issue.]

The classic LMA had somewhat complicated design like two different spring rates enclosed in that small diameter cyl that if the car was kept in the storage for months, some of the LMA will lose spring tension more than others resulting in tappetty sound.

It’s the result of mid rocker arm not following the profile of mid cam robe and simply both are hitting each other making the mechanical noise.

This is the typical sound of tired LMA. The noise is always there from the beginning but suddenly disappears around 0:40 - 0:45 and 0:56 - 1:05.

This is what’s happening with the tired LMA. As you can see, the spring rate is different from one LMA to the other.

With the latest LMA design, it’s much simpler design with just the spring and with no cyl surrounding, the gauge diameter and spring body diameter are much larger than the classic one that the initial spring rate is much higher.

Should last for a long time.

The changeover happened at the time when LEV engine was introduced in 99 but depending on the market, it’s probably called as 00 model.

As the introduction timing depends on each market, best to enter the VIN in the online parts website based in one’s country.

If your engine is pre-LEV, the latest LMA is 14820-SL0-305.

You will see thin metal silver colour spacer and hat at both ends of the spring.

If your engine is LEV, you already have the latest LMA design from the factory and it can survive for a long time.

So far, I have never replaced the LMA on LEV engine.

The last 3 digits of the parts no. is -003 and it will have just the silver hat at the top

without the spacer at the base.

Again, if you see -003 for the LMA when you entered your VIN, your NSX already has the latest LMA design so unless you have a reason to do so, no need to replace.

Kaz.