Just to add to the wisdom here, I did not find it too difficult to do this in situ:

Remove the VTEC solenoids, and the overflow bottle, disconnect the 3 coolant hoses from the firewall before you get started

Parts (in addition to timing belt)

4 aluminum crush washers for the hex plugs 12209-PR3-000

4 rubber o rings for the banjo dowel pins that go into tubes (91306-PJ4-000)

An M5-0.8 bolt

like this to remove them. Also use a passenger side engine mount bolt to thread into the tubes themselves to pull out (free)

And 2 cam cap o rings (91308-PH9-000 aka 91302-GE0-000)

and 4 cam plugs (12513-PR7-A00)

and 4 cam seals (91213-PR7-A01)

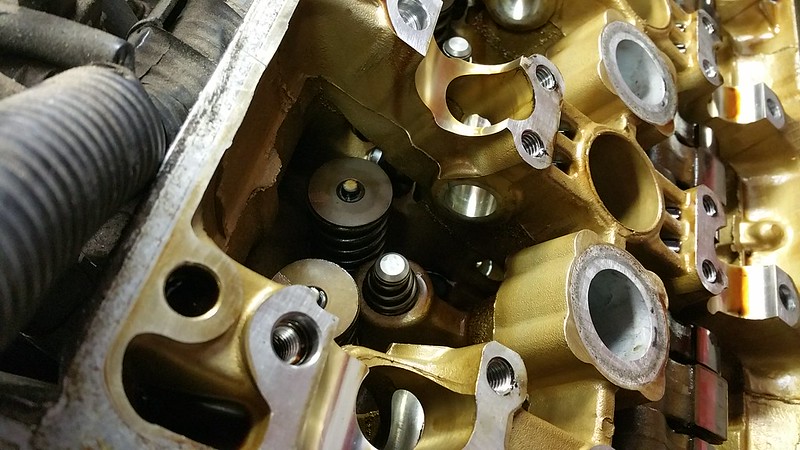

and 12 replacement LMAs (14820-PCB-305)

And VTEC solenoid seals (2 each of 36172-PR3-005, 15825-PR3-005)

Late edit: I did this preventatively on my 94. All the old hydraulic LMAs passed the finger spring test, but the engine idled a little more tappetey than I remember it doing years ago. Since I was doing the cam seals anyways, this seemed like a good 'while you are in there'. The engine does idle quieter and smoother than did before, so I wonder if the hydraulic LMAs were 'good' but perhaps not as good as they once were.