I though this might be interesting for those interested in manifold design and understanding there design and workings.

First of al chronological format of the C-Series engine:

C25A (1985)

C27A < introduces advance torque control manifold aka VISS

C20A

C20AT (variable turbo, also used in early prototype NSX)

C30A < NSX Engine

C32A < Legend G2 engine 3 main versions, Type-I base torque tune, Type-II rpm/sport tune, OBD-II TL (rare)

C35A A tall deck version of C32A interesting note, a balance shaft is used to eliminate vibrations due to '90 configuration

C32B < 97-05 NSX

Non production "street" engines that are noteworthy, (race engines are a different interesting topic)

C35"B" NSX/Legend hybrid first used in FS-X prototype sedan

C35"B" larger NSX engine displayed on the HSC prototype

Very novel approach in the first generations of the C engine is the use of SOHC with a push rod in the head to give DOHC valve angles.

Head layout then split in to two directions in the late eights

C30A/C32B went with a B-Series configuration

C32A/C35A went with a D-Series SOHC configuration

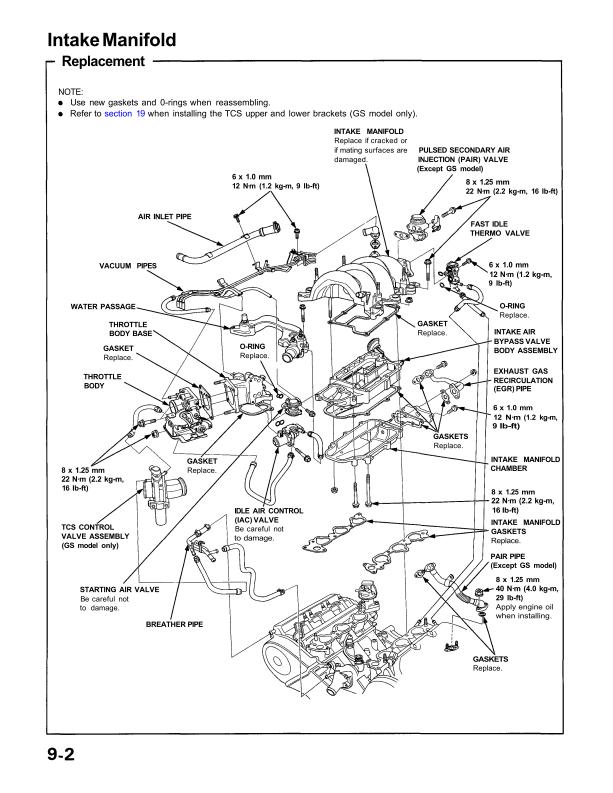

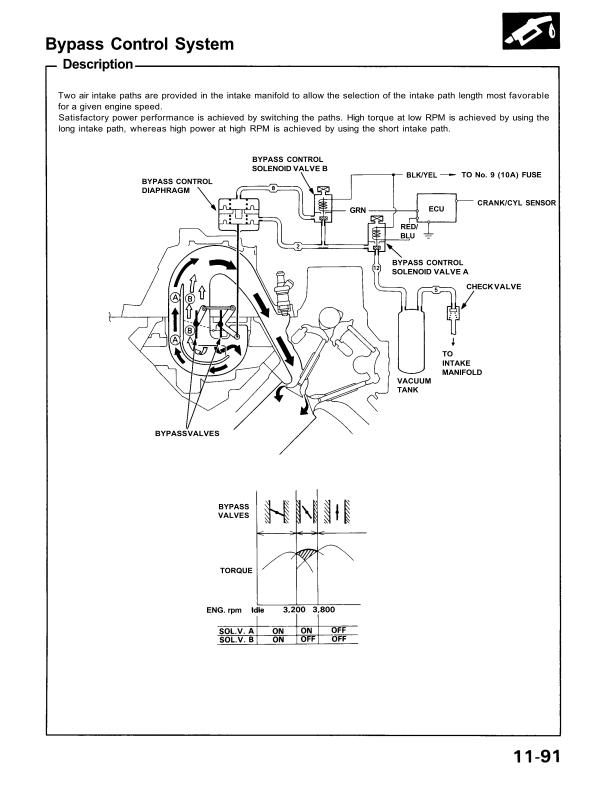

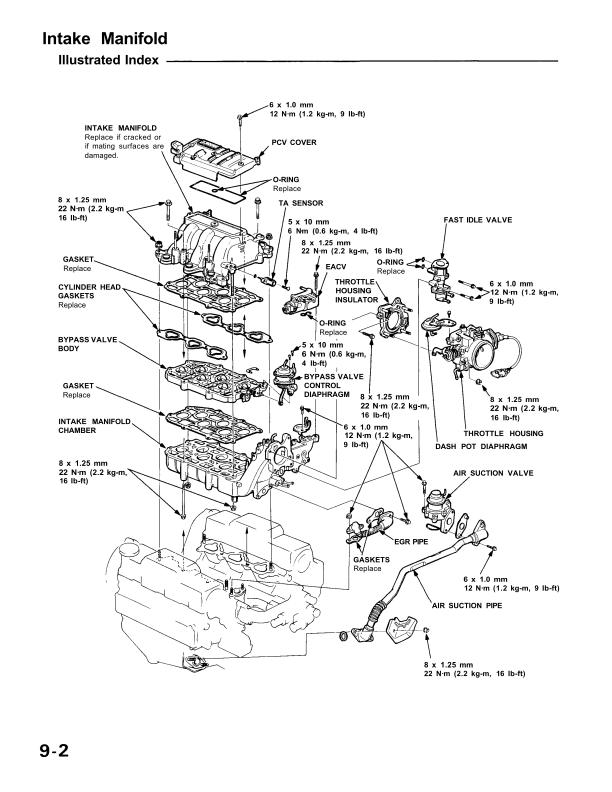

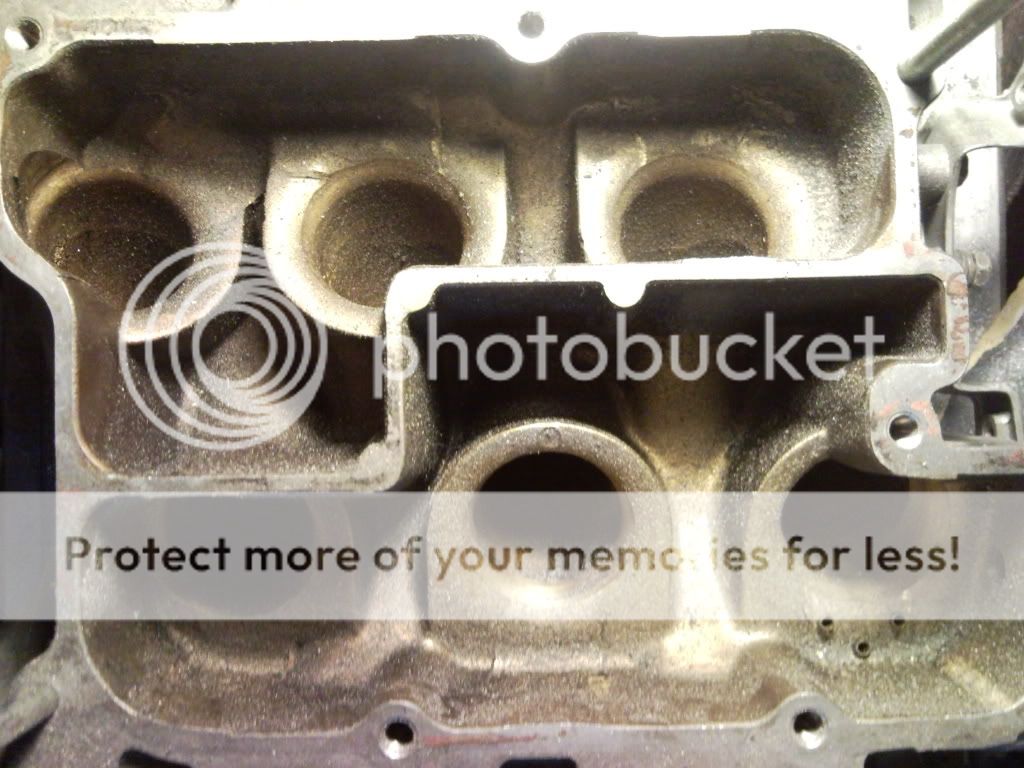

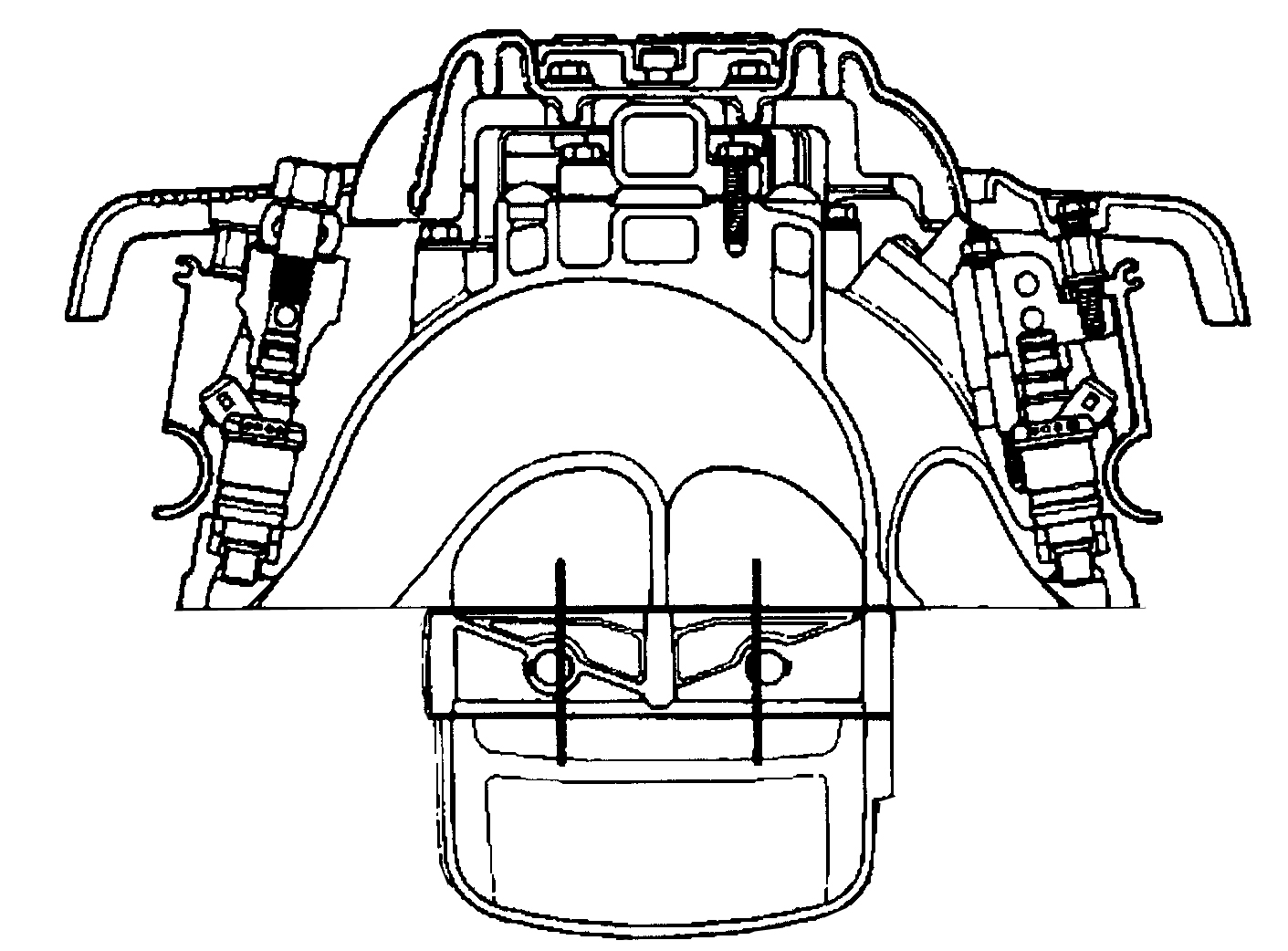

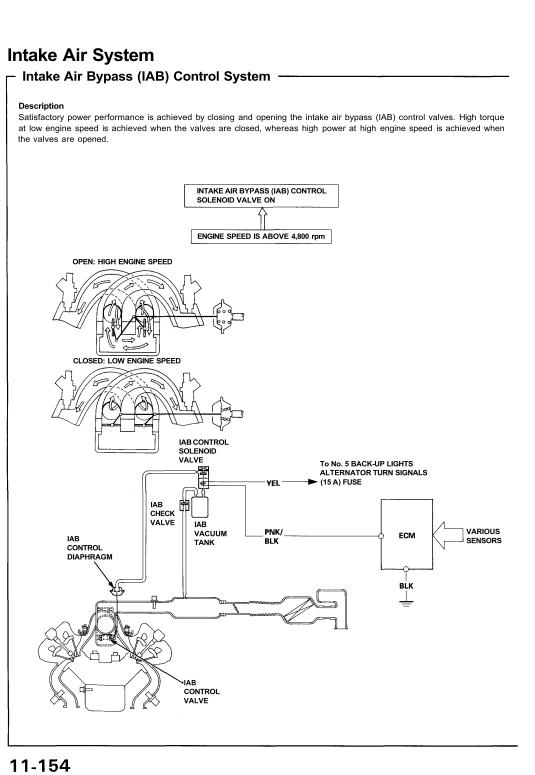

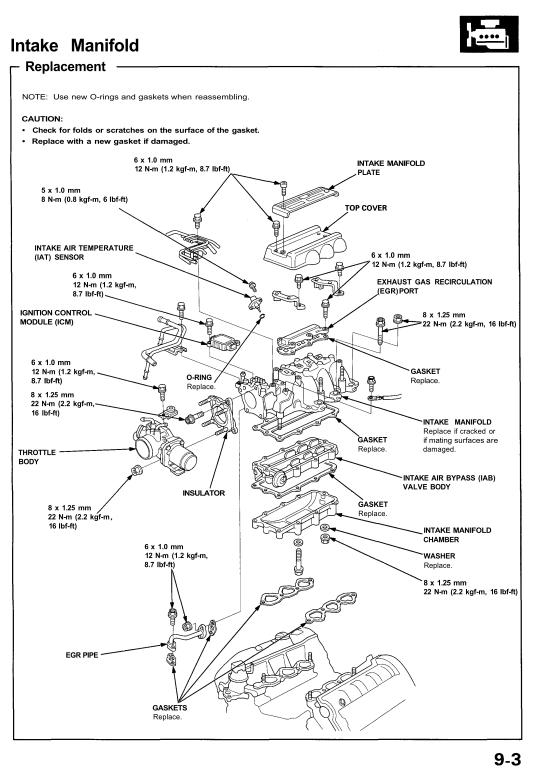

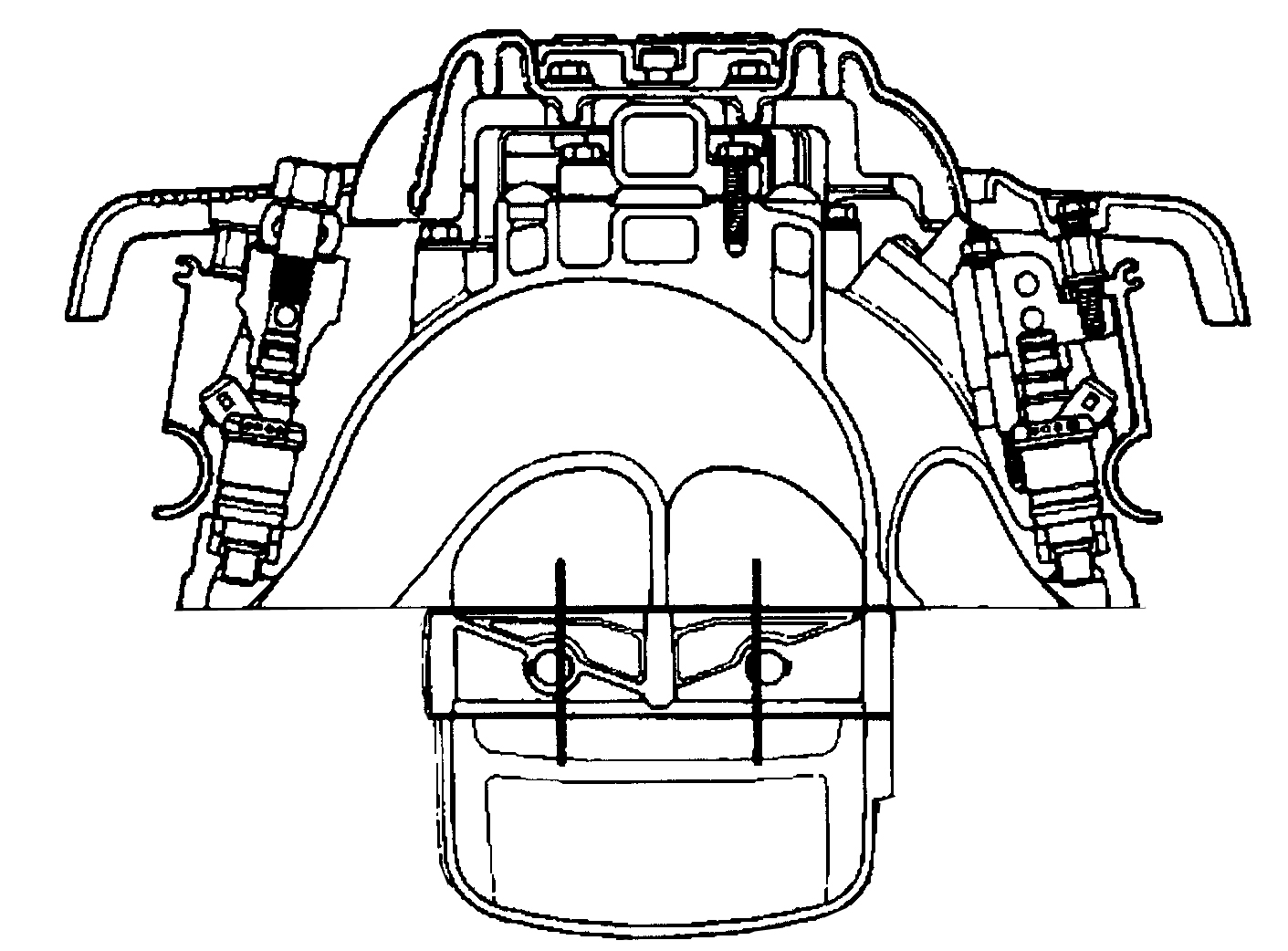

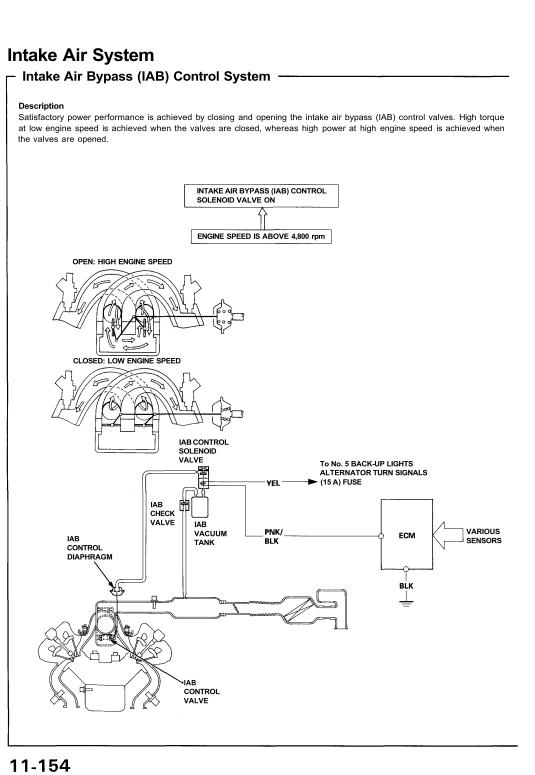

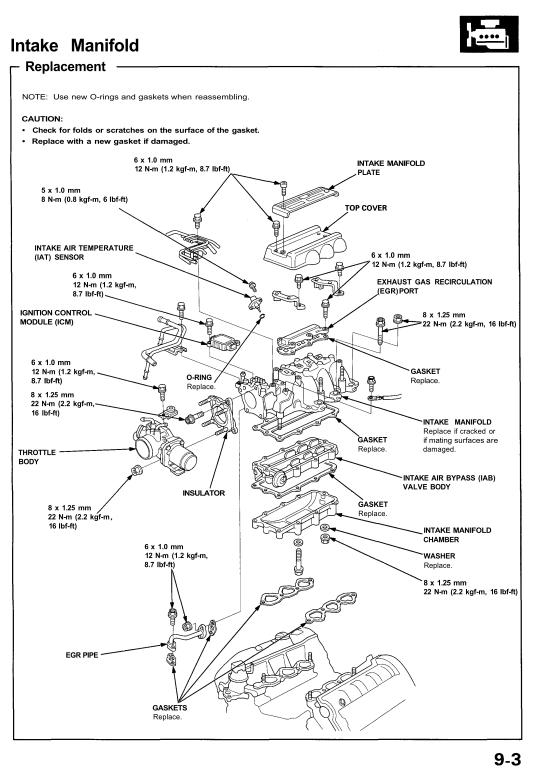

NSX Intake manifold (basically identical between 3.0L and 3.2L engines)

First of al chronological format of the C-Series engine:

C25A (1985)

C27A < introduces advance torque control manifold aka VISS

C20A

C20AT (variable turbo, also used in early prototype NSX)

C30A < NSX Engine

C32A < Legend G2 engine 3 main versions, Type-I base torque tune, Type-II rpm/sport tune, OBD-II TL (rare)

C35A A tall deck version of C32A interesting note, a balance shaft is used to eliminate vibrations due to '90 configuration

C32B < 97-05 NSX

Non production "street" engines that are noteworthy, (race engines are a different interesting topic)

C35"B" NSX/Legend hybrid first used in FS-X prototype sedan

C35"B" larger NSX engine displayed on the HSC prototype

Very novel approach in the first generations of the C engine is the use of SOHC with a push rod in the head to give DOHC valve angles.

Head layout then split in to two directions in the late eights

C30A/C32B went with a B-Series configuration

C32A/C35A went with a D-Series SOHC configuration

NSX Intake manifold (basically identical between 3.0L and 3.2L engines)

Last edited: