Awesome, Just great.

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thanks everybody for following, it really helps.

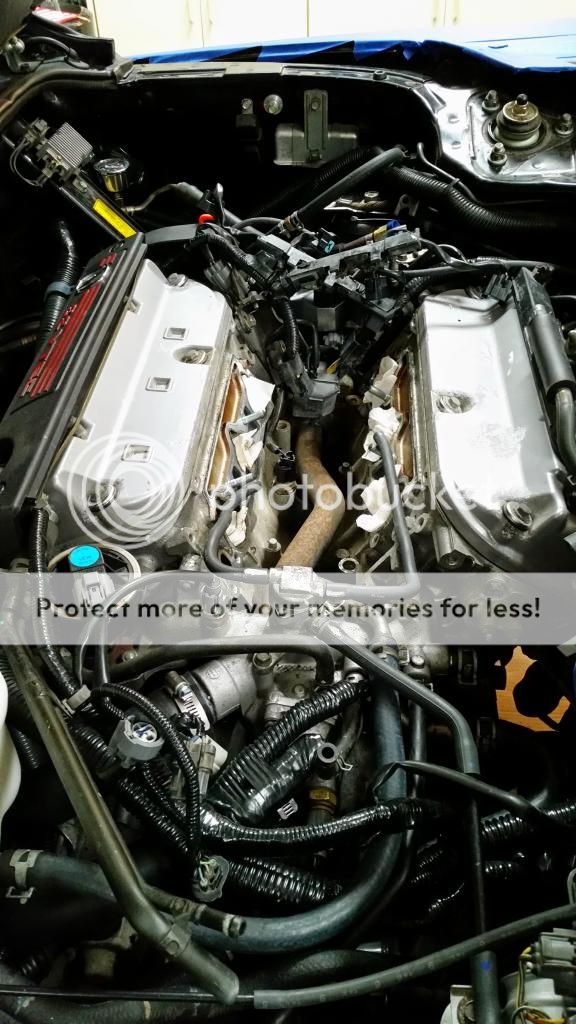

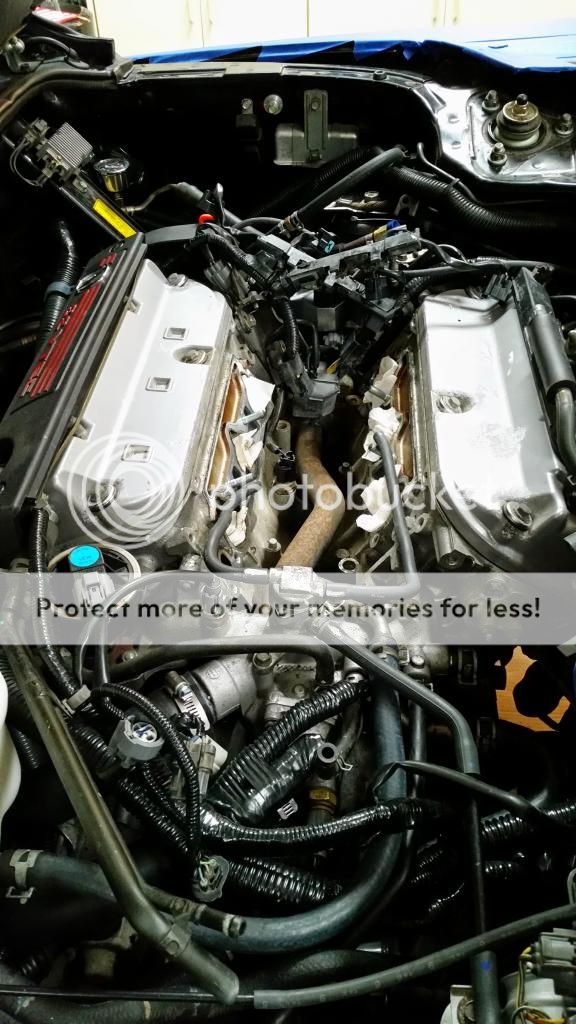

Well yesterday was one big step forward and today I got set back a few steps. I have a coolant leak that appears to be from the cross pipe in the valley of the engine that goes from the water pump to the thermostat manifold, the fuel line does not stay pressurized after I shut off the engine and there is quite a fuel vapor smell after the engine is off, I think it is a bad injector. But the worst news is that the passenger axle hits the axle bracket, actually not too big a deal for the DBC block, I can cut the bracket back and it will clear, but this bracket may not work for the DBW blocks. I will press on.

As for those of you planning on using a DBW J-series motor, this kit may not work for you. The front mount adapter and axle bracket may not work. That is not to say that it can't be done, I just don't know.

Well yesterday was one big step forward and today I got set back a few steps. I have a coolant leak that appears to be from the cross pipe in the valley of the engine that goes from the water pump to the thermostat manifold, the fuel line does not stay pressurized after I shut off the engine and there is quite a fuel vapor smell after the engine is off, I think it is a bad injector. But the worst news is that the passenger axle hits the axle bracket, actually not too big a deal for the DBC block, I can cut the bracket back and it will clear, but this bracket may not work for the DBW blocks. I will press on.

As for those of you planning on using a DBW J-series motor, this kit may not work for you. The front mount adapter and axle bracket may not work. That is not to say that it can't be done, I just don't know.

Great Job !!!! Congrats keep pushing!!!

This is valuable information. I was looking to see if something like this will fit with a transverse transmission.

I like where you're going with this. It's been on my mind for a while.

Congrats on the start up. Can't wait to see her on the road.

Here's the rest of your video:

Here's the rest of your video:

Congrats on the start up. Can't wait to see her on the road.

Here's the rest of your video:

LOL, Matt

In diagnosing the fuel and coolant leak I dug into the valley of the engine but did not find a coolant leak, which was good, but I did find a lot fuel. The coolant leak appears to have been coming from a faulty hose clamp.

The fuel leak was from the injectors leaking past the P2R fuel rails. I have tried all sorts of “fixes” but could not get the OEM injectors to seal in the P2R fuel rails. The P2R fuel rails allow the OEM injectors to push past the seal point of the rail and cause a massive fuel leak. The OEM fuel rails have a stop that won’t allow the injectors to push into the rail past the seal. I checked with P2R and they said that they have never had this problem on their race car, however I suspect they are not running OEM injectors. So, for now I picked up a set of 2000 Honda Odyssey fuel injector rails that are the flow through design and should not have the vapor lock / hot start problem that the TL fuel rails suffer from. Now, I just have to reverse the Odyssey rails and do some simple tweaking to get them to fit.

Since I had the injector bases out, I decided to go ahead and do a simple polish on them. Here is what the intake manifold runners look like, the injector bases were similar.

I polished the injector bases with 60, 80 then 120 grit. I don’t know if it will be much improvement, but they sure look better.

The fuel leak was from the injectors leaking past the P2R fuel rails. I have tried all sorts of “fixes” but could not get the OEM injectors to seal in the P2R fuel rails. The P2R fuel rails allow the OEM injectors to push past the seal point of the rail and cause a massive fuel leak. The OEM fuel rails have a stop that won’t allow the injectors to push into the rail past the seal. I checked with P2R and they said that they have never had this problem on their race car, however I suspect they are not running OEM injectors. So, for now I picked up a set of 2000 Honda Odyssey fuel injector rails that are the flow through design and should not have the vapor lock / hot start problem that the TL fuel rails suffer from. Now, I just have to reverse the Odyssey rails and do some simple tweaking to get them to fit.

Since I had the injector bases out, I decided to go ahead and do a simple polish on them. Here is what the intake manifold runners look like, the injector bases were similar.

I polished the injector bases with 60, 80 then 120 grit. I don’t know if it will be much improvement, but they sure look better.

Last edited:

I finished modifying and installing the Odyssey fuel rails and the fuel leak is gone.

Again, I would not recommend using the P2R fuel rails with OEM injectors. The 2000 Honda Odyssey fuel rails are easily modified, far safer and you can pick them up at a Pick-N-Pull for $28.

Since the intake manifold was off, I took an extra hour to check and adjust the valves on the J-series. All of the valves were way looser than spec but they are super easy to adjust. I picked up a Honda valve adjusting tool a long time ago and it makes adjusting the valves so much easier, I would recommend one even if you were only going to use it once.

How long does it take to adjust the valves on a C-motor?

That valve train has over 100,000 miles on it. Looks pretty clean to me!

Nice roller rockers!

My NSX is now officially J-powered!

That is my son's "Bug Eye" WRX in the background, he thinks he gets to pull into the garage now.

Again, I would not recommend using the P2R fuel rails with OEM injectors. The 2000 Honda Odyssey fuel rails are easily modified, far safer and you can pick them up at a Pick-N-Pull for $28.

Since the intake manifold was off, I took an extra hour to check and adjust the valves on the J-series. All of the valves were way looser than spec but they are super easy to adjust. I picked up a Honda valve adjusting tool a long time ago and it makes adjusting the valves so much easier, I would recommend one even if you were only going to use it once.

How long does it take to adjust the valves on a C-motor?

That valve train has over 100,000 miles on it. Looks pretty clean to me!

Nice roller rockers!

My NSX is now officially J-powered!

That is my son's "Bug Eye" WRX in the background, he thinks he gets to pull into the garage now.

Last edited:

Did you solve the axle bracket issue?

You sir, are a steely-eyed missile man.

Lucas

BTW the painter's tape is a great move.

Lucas

BTW the painter's tape is a great move.

That valve train has over 100,000 miles on it. Looks pretty clean to me!

No kidding; that's amazing!

Great to see that you finally completed the project. Congratulation's.

"Bug eye's" are great. My daily is just crossed over 200k miles with the stock turbo.

"Bug eye's" are great. My daily is just crossed over 200k miles with the stock turbo.

congrats on the j swap... looks amazing

Thanks everyone for all of your support. I got the car out for a drive around the block yesterday and it sure felt good to be back in the seat! It ran good and strong and sounded good. I do have some check engine codes that I am resolving, mostly due to the missing automatic transmission but I have already resolved most of them. Due to the codes, the engine will only rev to 5000 RPM. The engine coolant temperature gauge and the speedometer aren't working. I'll keep working on it.

- - - Updated - - -

Yes, for the DBC block, I had to grind off another 1/8". For the DBW block I will have to find a flat socket head bolt in M10x1.25 then adjust the bracket design.

- - - Updated - - -

Thanks Marc. I will try hard to get a meet/drive scheduled by the end of summer. I am anxious for some back to back comparisons and see what people think.

- - - Updated - - -

Did you solve the axle bracket issue?

Yes, for the DBC block, I had to grind off another 1/8". For the DBW block I will have to find a flat socket head bolt in M10x1.25 then adjust the bracket design.

- - - Updated - - -

Great job David. Make sure you setup some type of meet/drive with this running before the summers end.

Thanks Marc. I will try hard to get a meet/drive scheduled by the end of summer. I am anxious for some back to back comparisons and see what people think.

Last edited:

For the DBW block I will have to find a flat socket head bolt in M10x1.25 then adjust the bracket design.

You may be familiar already but this is always a good place to find such things:

http://www.mcmaster.com/#low-profile-head-socket-cap-screws-m10

You may be familiar already but this is always a good place to find such things:

http://www.mcmaster.com/#low-profile-head-socket-cap-screws-m10

Thanks you. Yes, I have used McMaster-Carr before and they are great. The trouble is finding an M10x1.25 (fine thread) flat head socket cap screw.

- - - Updated - - -

Amazing!!! Videos please sir!

Thank you. What kind of videos are you looking for?

Ah, I'm a doofus. Looks like those are tough to track down. There's an idea here to get a long M10x1.5 that is not fully threaded, cut off the threads, and use a fine-pitch die to thread the remainder. That seems like an awful lot of trouble.The trouble is finding an M10x1.25 (fine thread) flat head socket cap screw.

Shot man good to see, may have a spare couple of those lying around from when I got some made :/ will pm you. Hopefully can clear the rest of those fault codes easy enough. We'll done

Great progress man........... offers a great alternative to those who might want to venture that way........ and hey, the longer the new NSX keeps setting itself on fire, the longer we all still drive the only supercar Honda ever made !!

Similar threads

- Replies

- 11

- Views

- 685