More than likely most of you have seen this already, but I'm reposting it here just to make sure I'm not missing anyone.

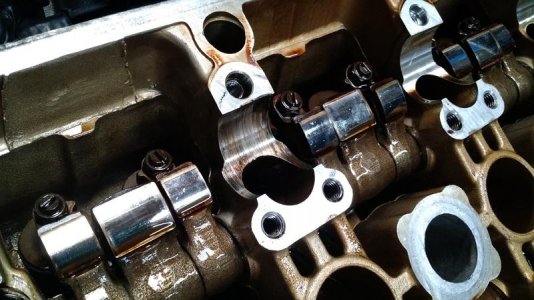

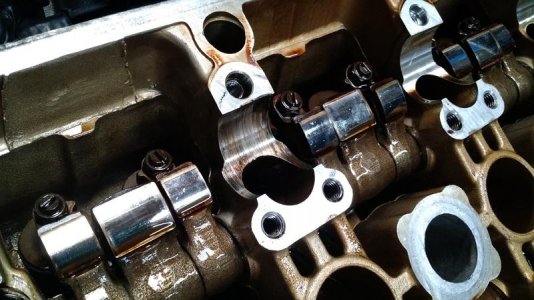

I recently had a front cyl head intake cam journal wipe out. The car has never been tracked, but it has sat in storage with only intermittent use over the past 15 years. Oil pressure is good. What I don't know is the type of oil that has been used in the car.

Apparently this is not an uncommon failure, but so far everyone appears to be guessing as to why its happening. Where I did my repairs there is another NSX with the same failure. The failure is always occurs on the front head exh cam. One thing to keep in mind is that this area is the last area to see oil pressure on startup.

In the hope of preventing it from happening again I am using only top for the line oil (Penzoil Ultra Synthetic 10w 30w) and I have installed a baffle in the oil pan. One more step I could take is going to a high efficiency oil pump and then using a 5w 30w oil.

Anyone other than the few I already know about have this problem, and what are your opinions on what caused it?

I recently had a front cyl head intake cam journal wipe out. The car has never been tracked, but it has sat in storage with only intermittent use over the past 15 years. Oil pressure is good. What I don't know is the type of oil that has been used in the car.

Apparently this is not an uncommon failure, but so far everyone appears to be guessing as to why its happening. Where I did my repairs there is another NSX with the same failure. The failure is always occurs on the front head exh cam. One thing to keep in mind is that this area is the last area to see oil pressure on startup.

In the hope of preventing it from happening again I am using only top for the line oil (Penzoil Ultra Synthetic 10w 30w) and I have installed a baffle in the oil pan. One more step I could take is going to a high efficiency oil pump and then using a 5w 30w oil.

Anyone other than the few I already know about have this problem, and what are your opinions on what caused it?

Last edited: