Need advice on runner/plenum lengths/dimensions/volume and general advanced design details for 6000-7000 RPM max power goals.

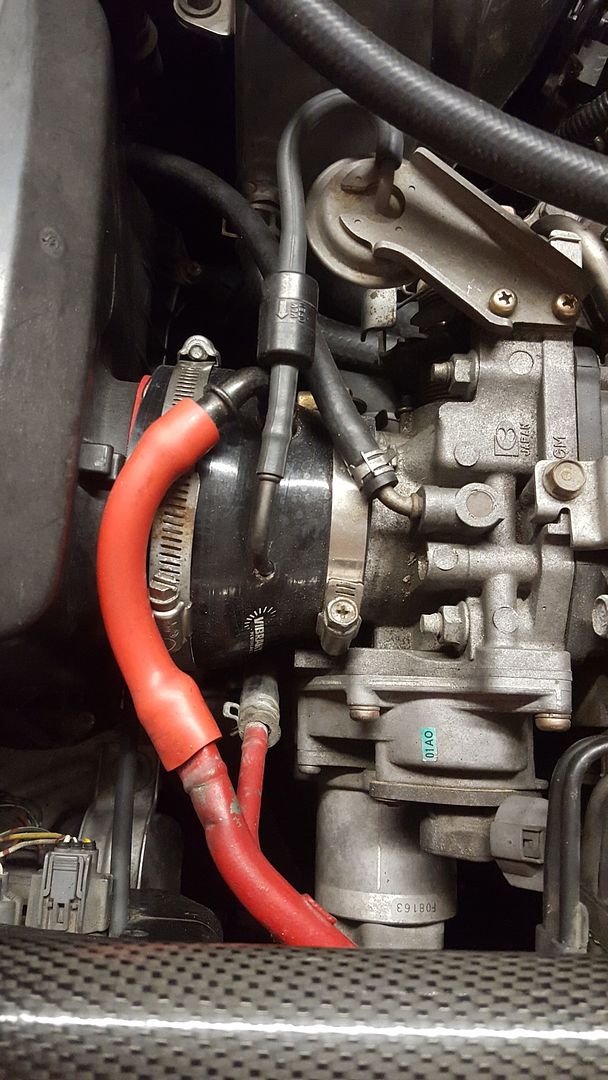

Ive been working on this experiment for a while.... and have modifed a spare OEM manifold to make a N/A custom Carbon fiber manifold and now plan on finishing this in next week or so.... The goal is to reduce 25lbs from the top most heavy section of the NSX, and hopefully gain 5-10whp in upper areas of power band through Reduced IAT's since fiberglass and/or CF have substantially lower thermal conductivity properties than aluminum and better mid-high RPM airflow design... Yes, the DMS manifold exists, it does not reduce thermal conductivity since its aluminum and it does not specifically focus on N/A power benefits.

using a skunks or blox 70-74MM billet throttle body and a pro-speed thermal intake gasket

debating on dual or single plenum, and/or to connect/round the end of the dual plenum to recirculate air

debating on focusing on mid to high RPM gain, but looking for more overall power "under the curve"

I'm willing to make 2-3 versions and test back to back on Dyno.

Some facts I've measured:

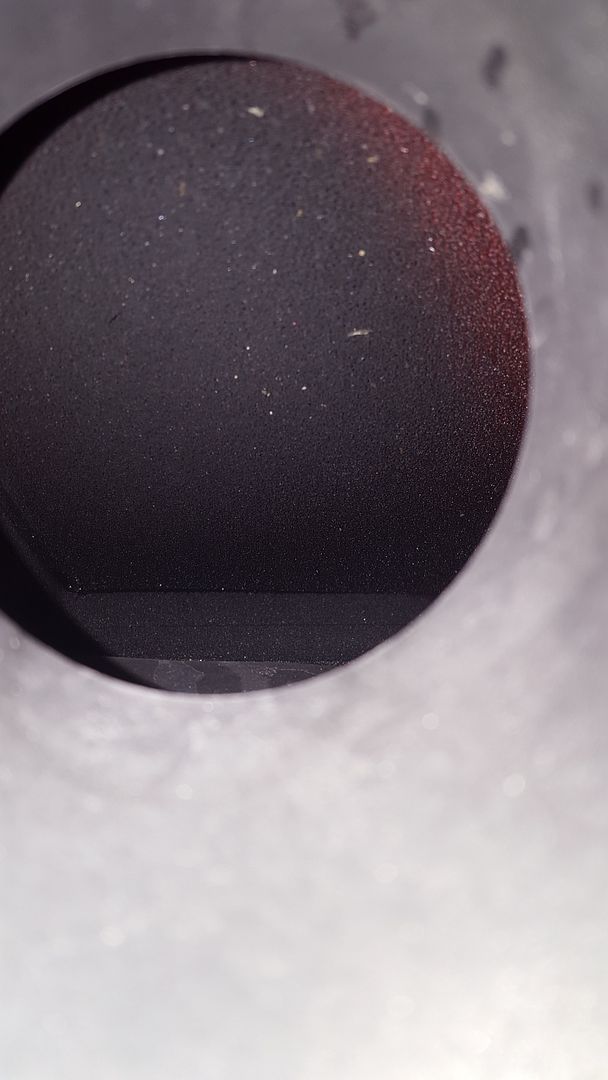

upper OEM manifold is about 130 ounces 3.8L

lower magnesium secondary manifold is 40 ounces 1.1L

(did not measure center butterflies section)

OEM manifold weighs about 23.5 lbs (see pic) with fuel rails and 21.5lbs without fuel rails

the OEM throttle body with all attachments is about an additional 10-11lbs

around 33-35lbs total

the finished assembly with throttle body goal is to weigh about 9lbs thus a 25lbs savings.

FYI. This not a business venture, not looking to produce these.

Yes my wife is pissed at me for working on this on the kitchen counter top and balcony.

examples of manifolds: https://www.google.com/search?q=por...h=829#tbm=isch&q=carbon+fiber+intake+manifold

Ive been working on this experiment for a while.... and have modifed a spare OEM manifold to make a N/A custom Carbon fiber manifold and now plan on finishing this in next week or so.... The goal is to reduce 25lbs from the top most heavy section of the NSX, and hopefully gain 5-10whp in upper areas of power band through Reduced IAT's since fiberglass and/or CF have substantially lower thermal conductivity properties than aluminum and better mid-high RPM airflow design... Yes, the DMS manifold exists, it does not reduce thermal conductivity since its aluminum and it does not specifically focus on N/A power benefits.

using a skunks or blox 70-74MM billet throttle body and a pro-speed thermal intake gasket

debating on dual or single plenum, and/or to connect/round the end of the dual plenum to recirculate air

debating on focusing on mid to high RPM gain, but looking for more overall power "under the curve"

I'm willing to make 2-3 versions and test back to back on Dyno.

Some facts I've measured:

upper OEM manifold is about 130 ounces 3.8L

lower magnesium secondary manifold is 40 ounces 1.1L

(did not measure center butterflies section)

OEM manifold weighs about 23.5 lbs (see pic) with fuel rails and 21.5lbs without fuel rails

the OEM throttle body with all attachments is about an additional 10-11lbs

around 33-35lbs total

the finished assembly with throttle body goal is to weigh about 9lbs thus a 25lbs savings.

FYI. This not a business venture, not looking to produce these.

Yes my wife is pissed at me for working on this on the kitchen counter top and balcony.

examples of manifolds: https://www.google.com/search?q=por...h=829#tbm=isch&q=carbon+fiber+intake+manifold

Last edited: