I recently began the process of taking the car out of Winter storage.

As I pulled the plugs to crank the engine over, I noticed that one of my aftermarket Goodridge fuel fittings had cracked. This wasn't the fitting per se, but the socket that threads the hose onto the fitting. It was a place I never thought a failure could occur.

It was a clean through-wall crack the length of the socket. The only seal against my ~60 psi of fuel would have been the Teflon/Kevlar braided hose threaded onto the fitting. Obviously not good.

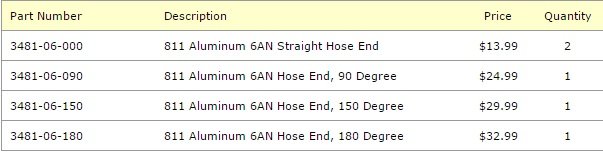

I googled and didn't come up with any other failures of this type. I was very careful when assembling these (only used aluminum clamps), and didn't nick these on the ends where they would have stress risers. The only thing I can think of is a bad batch of aluminum made it through QC and were made into the sockets. Goodridge is a relatively good name, and I used the expensive 910 Teflon-lined, Kevlar-braided fuel hose. One forged 6AN fitting is $25. I emailed Goodridge about three business days ago and have had no response.

I checked over all of my other 6AN fittings (fuel), 4AN fittings (brakes), and 12AN fittings (oil), and didn't observe any other defects. There is only one location I could not get access to (the fuel sending line out of the top of the tank). I'll need to borrow a boroscope from work to inspect that.

Just FYI - Always check the condition of your fuel, oil, and brake systems. Obviously, this is due to aftermarket problems and self-inflicted in my case, but those with OEM fuel hoses are getting old and cracked too.

Dave

View attachment 132993

As I pulled the plugs to crank the engine over, I noticed that one of my aftermarket Goodridge fuel fittings had cracked. This wasn't the fitting per se, but the socket that threads the hose onto the fitting. It was a place I never thought a failure could occur.

It was a clean through-wall crack the length of the socket. The only seal against my ~60 psi of fuel would have been the Teflon/Kevlar braided hose threaded onto the fitting. Obviously not good.

I googled and didn't come up with any other failures of this type. I was very careful when assembling these (only used aluminum clamps), and didn't nick these on the ends where they would have stress risers. The only thing I can think of is a bad batch of aluminum made it through QC and were made into the sockets. Goodridge is a relatively good name, and I used the expensive 910 Teflon-lined, Kevlar-braided fuel hose. One forged 6AN fitting is $25. I emailed Goodridge about three business days ago and have had no response.

I checked over all of my other 6AN fittings (fuel), 4AN fittings (brakes), and 12AN fittings (oil), and didn't observe any other defects. There is only one location I could not get access to (the fuel sending line out of the top of the tank). I'll need to borrow a boroscope from work to inspect that.

Just FYI - Always check the condition of your fuel, oil, and brake systems. Obviously, this is due to aftermarket problems and self-inflicted in my case, but those with OEM fuel hoses are getting old and cracked too.

Dave

View attachment 132993