I took my LoveFab turbocharged NSX to a local tuning shop to measure it's power as I was suspecting the car was well below it's 400 rwhp target.

In fact the car pulls very well to about 5000 rpm and then the rush goes away until you reach redline.

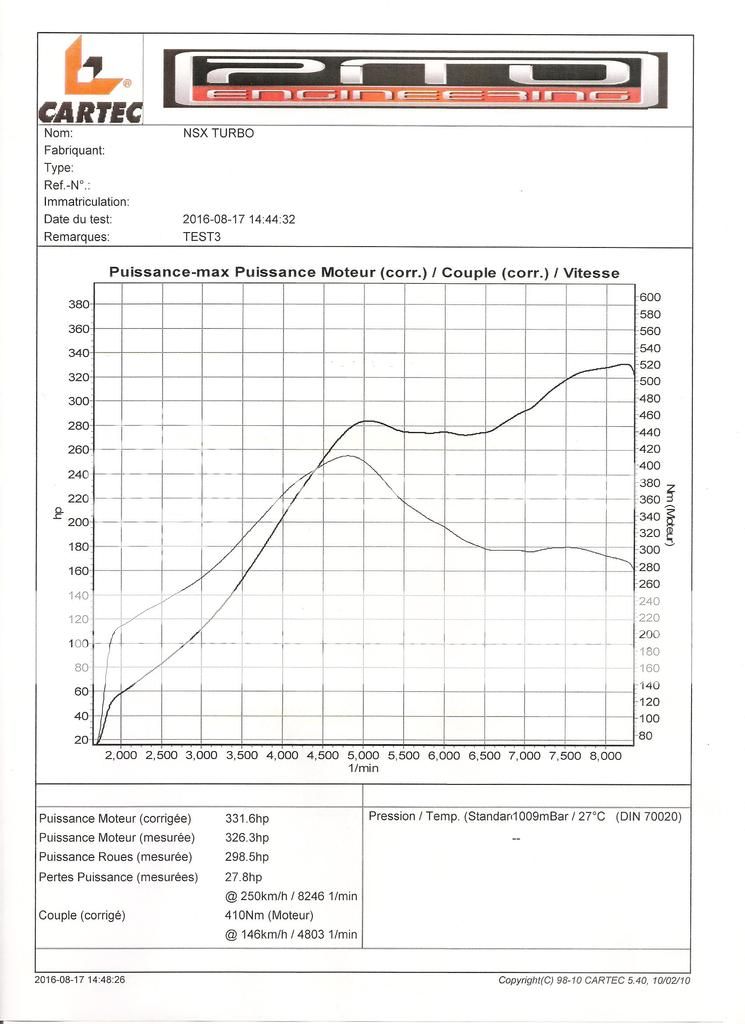

The graph below shows exactly what's happening:

280 hp at 5000 rpm followed by a dip to then slowly rise to 330 hp at 8250 rpm.

The torque is very generous at 410 Nm at 4800 rpm.

The engine is a 3 L model with stock internals and I'm running no more than 8 PSI of boost.

Fuel is 98 Octane.

What could the issue be?

Looking at the curve, I get the feeling that the VTEC is not working?

I'll look into the manual to determine if this could be the case?

I had a quick look at my AEM EMS calibration file and it looks OK to me?

The Vtec is programmed to come on at 4800 rpm and 60% TPS.