One pot is for calibration of the speedo, the other for calibration of the tach. The electronic circuit in the tach is a moderately accurate pulse frequency to voltage converter (the tach meter being in effect a voltmeter). Because of the rather loose tolerances that go into the components, the circuit is provided with the calibration pot which is adjusted to provide a reasonable degree of accuracy. With the exception of the idle reading, your test results suggest that the dash tach is reading consistently low which you may be able to fix with the calibration pot. I really don't know what is up with the idle reading (other than the observation that your car seems to be idling really fast - normal warm idle on a manual shift is kind of 800- 900 RPM; but, that is a separate issue). So, you may be able to bring the tach into a reasonable degree of agreement with 'true' RPM with the calibration setting.

But, heed jwmelvin's advise. The tach's calibration has changed for a reason and that reason is likely drifting / failing capacitors. If you manage to get it back into calibration with the pot, you may find that in a few months or so that the calibration is changing again. At some point the capacitor problem may become bad enough that there is not enough adjustment available to compensate. I also notice that based upon your measurements, the tach does not have a consistent % error versus engine speed. It looks like the slope of the calibration line has changed. So, you may be able to calibrate the tach to give you an accurate reading at one RPM; but, the other RPM values may be in error. Go ahead and see if you can calibrate the tach; but, I have a feeling that you are going to be doing the capacitor thing at some point.

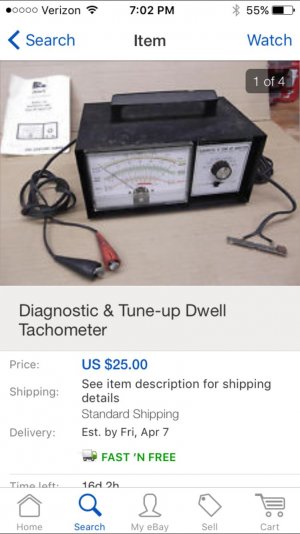

Final piece of advice. Before you mess up your cluster calibration, take your $30 tach and check its operation on another car. The fact that it is telling you that your car is idling at 950 - 1000 RPM makes me think that it may also be out of calibration.