I have had a rattle coming from under the NSX for a while and I recently tracked it down to a loos component. The frame that holds the shift linkage in place was missing a 14mm 10x30 bolt. I bought a replacement bolt and tried to install it, only to have the threaded hole rotate with the bolt. Is there a way to fix this?

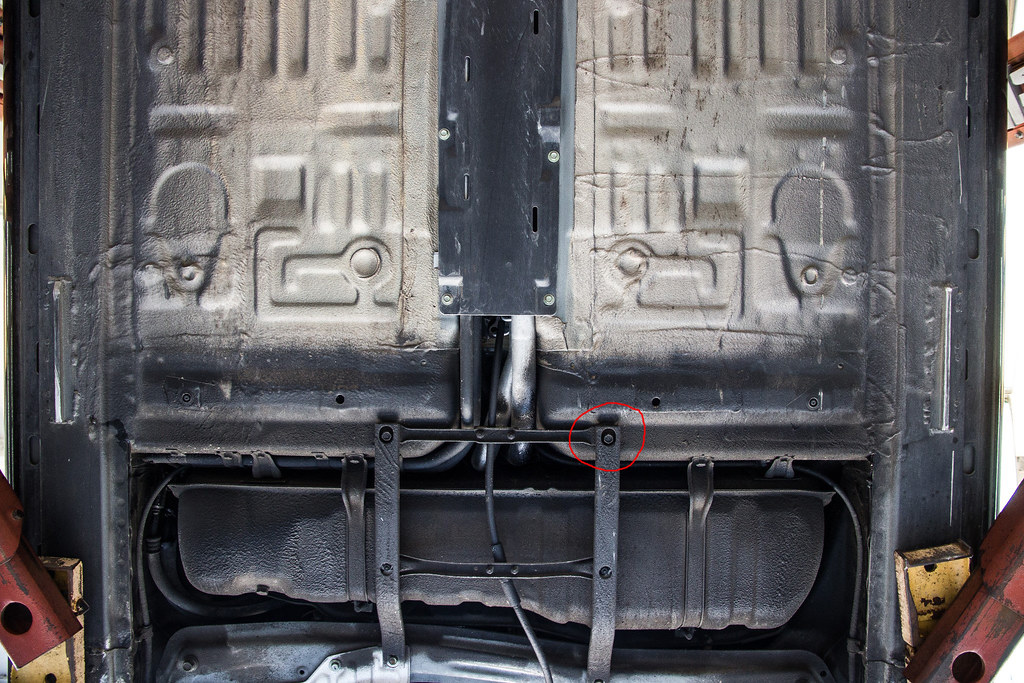

Frame with missing bolt:

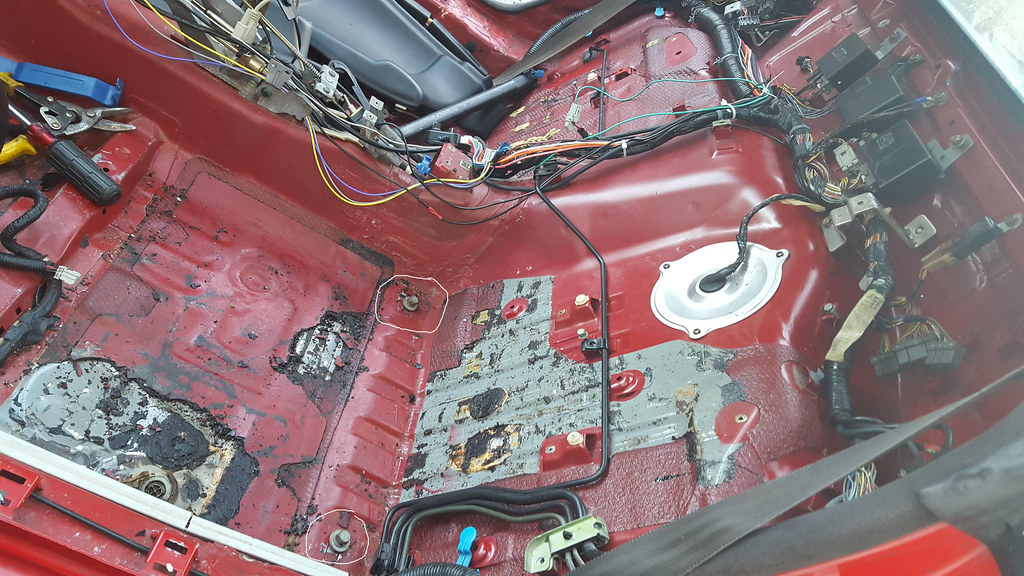

Threaded hole in body:

Frame with missing bolt:

Threaded hole in body: