RYU said:I'm caught up somewhat with this thread. I'm not sure I can help directly as I'm not modifying my factory ECU. I went straight to a HKS F-Con VPro which is quite frankly pretty old by today's standards but still quite good for our 30yr old car. I can share some of my findings that might help some of you on your tuning adventures.

Welcome to the party, Regan! First off, I'm SO pleased you decided to go back to NA for your car. It's the soul and drama of the NSX.

My main question: Why is there no talk of timing advance on the C motors here? Is this because it's common knowledge (which I'm not privy to) that added timing doesn't do much? Or is it because no one has tried? What are the current assumptions around this? Please share your opinions. I've heard here and there through general NSX chatter that this engine likes a lot of timing from tuners. I can verify some of that (see point 2 below)

I can add my information here for help. Hopefully others will chime in too. First, Mark Johnson told me many, many years ago that the NA1 NSX-R "hot chip" tune was identical to the regular NSX, but just with "a little more timing." While it might have yielded a few extra HP on that 100RON Japanese Super-Premium gas, it did nothing on US cars running US fuel. Chris W just dynoed a real R and found it identical to the US cars. Now that we have access to the factory tunes via TunerPro, we can check the NSX-R differences, but the SOS dyno test seems to validate the idea that adding timing on the NSX 3.0 liter doesn't translate to more power. Brian at Prospeed also advised me when I was considering a chip for my old 91 that adding timing does nothing for power- any gains are within the margin of error on a dyno. Finally, I follow the blogs of two serious NSX tuning houses (RFY and T3TEC) and, when discussing tuning timing, they leave it mostly stock, choosing to focus on fueling. Setting these points aside, it also seems that eating into the safety margin on timing isn't worth the small gains you get, if any. But, all of this advice is for a stock 3.0. Once you start changing the system (compression, RPM, cams, ITB, etc.) the old advice may not hold. In my opinion, once you change compression and/or cams, you're altering the fundamental nature of the fuel charge in the cylinder and timing might need to be addressed to restore ideal combustion.

* I'm using 1000cc Injector Dynamics (based off the Bosch EV14) with these ITBs and idle is not smooth at 800rpm but amazingly smooth at 1000-1100rpm. I'm considering trying RDX injectors but I find no need as i'm preparing for the 3.5L. Here's the eye opening part in terms of duty cycle... at idle i'm using 0.9% at redline WOT i'm at only 31%. 1000cc is too big for the 3.5L but it's the smallest Injector Dynamics sells these days. I bet that's because of the amazingly good low duty cycle performance.

I'd seriously consider moving to the RDX. They are going to deliver that low-rpm stability you get from Honda Genuine injectors and have more than enough headroom for safe duty cycles even with a 3.5 ITB car. Everyone on this thread is using them in their cars, so we will have a lot of field data as tuning gets underway. I would go with Brad's RDX fitment kit too.

* In regards to ignition timing advance. I've been lucky to be mentored by one of the best tuners to be involved in the NSX community. He was also an owner and was part of a team that set world records. Anyway, he shared with me his timing table. He's quite the conservative tuner and would gladly give up some power for added longevity and overall well being of the engine. Even on crap California gasoline at WOT redline his timing table is 9 degrees advance. I've personally used his map as a guideline and can go an added 3-5 degrees on top of that before noticing knock but added power is negligible so it's not worth being so close to the edge like that IMO. ITBs need to use Alpha N with MAP vacuum only useful as compensation during low load conditions so it's not quite appropriate to copy his map (nor the OEM for that matter) during the partial throttle cells.

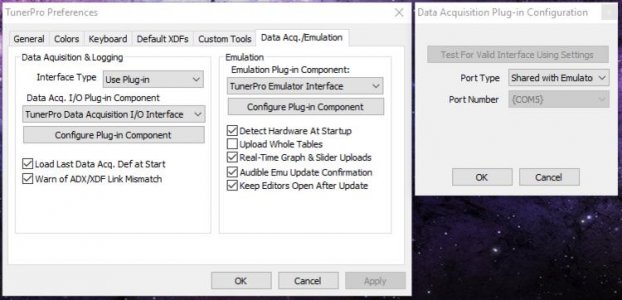

[MENTION=33247]MotorMouth93[/MENTION] is working on an Alpha-N tuning patch for the ECU that will permit stable ITB tuning. You should reach out to him. Since you are changing compression and cams, I'd mess around with timing a bit, but be careful. Based on the complicated knock routines in the OEM ECU, Honda was very, very concerned about knock in this engine. I'd probably start at stock timing on a dyno and then advance until either gains dropped off or I started to see knock. If I saw knock, I'd dial back by 10% just for safety margin. You'll find the sweet spot for your cams/pistons that way.

* I'm tuning WOT to 12.8. I like a little bit of cushion. Pretty much everywhere else in the map, from low load to medium load i'm anywhere from 15.5-13 AFR.

It looks like 12.7 to 13.0 is the sweet sport for WOT fuel on the 3.0. I'm street tuning to 12.9 myself, but will likely correct on the dyno if there is a small adjustment needed. I don't know if the HKS can run closed loop, but we're keeping it active for everyday cruising and linking it to throttle position (25% or less, for example).

* I've recently driven a Prospeed "custom tune" NSX. I have to admit.. I was quite impressed with the bottom end TQ. It was that noticeable. Because it was a "custom tune" I don't know which version of the chip it's closest to or is based off. I also recently drove a stock ECU NSX to compare to. What I was not impressed with the Prospeed was the roughness (for a lack of a better term). It was like comparing an 8bit to a 64bit, it was that rough.. even jerky in mid throttle low rpm parts of the map. The WOT TQ was impressive for just a reflash of sorts...

To be honest, now that we've had a chance to look at some of the various Prospeed tune versions, we weren't impressed. He never disabled or even changed closed loop operation, so the NSX ended up tuning out most of his fuel adjustments back to 14.7, except at WOT. The timing was not touched and the fuel changes were not smooth. We are aiming to be much more thorough. Now that we can control closed loop, there is a ton of torque to be unlocked in the midrange. One goal for this project is to have some really solid community tunes available based on hundreds of hours of tune time.

* Lastly, I also mentioned in the linked thread above... While I totally commend and support the research into the OEM ECU, I do believe a higher resolution tune from a modern ECU is worth it. Hell, i've been able to get ITBs to have driveability nearly like stock (98%'ish) - that's unheard of. It's actually noticeably smoother than the OEM ECU NSX I drove in many aspects like startup and high res control over AFR to name a couple. I know it's daunting to tune a fresh ECU (trust me.. I know) but if you have the time, it's worth it to have control over everything (tip in, decel, pressure compesators, speed compensators, barometer, nearly everything you can think of, even per cylinder AFR and timing if you want to get into the weeds). I know the cost might be prohibitive but I know some folks on here are spending mucho dinero on their cars and adding a standalone is not being considered... why?

My reason is that Honda spent more time and money than I will ever be able to muster getting the car starting and running smoothly in all conceivable driving conditions. All of that stability is baked into the programming and while we can tweak a lot of the parameters to dial in the car, there is a lot of stuff that is hard-coded into the ECU (the way that the ECU arrives at a final fuel pulsewidth, for example). I want to take advantage of that stability and just use my ECU to maximize the performance potential of the engine, which is about maybe 10% of the ECU definition.

EDIT: Something fun maybe you can helps me with. Let's assume I was able to dial in my fuel table with the 1000cc injectors on the stock 3.0L. As a baseline starting point for the 3.5L with higher lift cams and high CR on the same gas - might you add... say 15% more fuel globally as a starting point? I haven't thought of the math yet.. but eager to hear your suggestions. If cams are going in so will cam gears. That will be a whole other ball of wax...

My rule of thumb is the mathematical % increase plus another 5% for safety. It's better to be wrong rich than wrong lean.

EDIT 2: I was looking through the old Prospeed threads and found this interesting. I never looked into this before because I just wasn't interested. Have you seen his AFR plot? It's kind of all over the place, but what's more interesting is he's inheriting the OEM AFR curve. This lends me to believe he doesn't have control over the actual fuel map individual cells? I'm not quite sure honestly... but my question is.. why not try to flatten those peaks and valleys? That's probably why the car I drove had some roughness.

As noted above, the Prospeed tunes left a lot to be desired.

Last edited: