R-134a A/C Conversion

I finished up my R-12 to R-134a A/C conversion this weekend so here's a walkthrough of my experience. It was my first time messing with A/C systems but this presumably should be in my wheelhouse as a chemE

. Long post but hopefully it can serve as a bit of a DIY guide for others.

First off, some references I pulled together:

-Kaz explanation of compressor choices (

http://www.nsxprime.com/forum/showt...ith-a-94-or-newer/page2?p=1996629#post1996629)

-Kaz NSXUK blog posts (

http://www.nsxcb.co.uk/entry.php?1318-Koyo-Rad-Cooling-Sys-Washer-motor-04&goto=next) and (

http://www.nsxcb.co.uk/entry.php?1837-AC-Refresh-02&goto=prev)

-Joe G's in-dash HVAC unit vid, I didn't mess with it yet (

https://www.youtube.com/watch?v=ga7aT63fkE4) and HVAC rebuild thread (

https://www.facebook.com/groups/7990613243/permalink/10156770275213244)

-Adam S's compressor replacement vid (

https://www.youtube.com/watch?v=967Q30N-Q-s)

-Low refrigerant symptoms (

http://www.nsxprime.com/forum/showt...at-the-same-time?p=48762&viewfull=1#post48762)

-More Prime reading (

http://www.nsxprime.com/forum/showthread.php/202120-AC-Overhaul-advice-needed!)

Parts used:

-Denso 471-1194 New Compressor with Clutch (need to re-use old clutch/pulley/field coil assy)

-Denso Retrofit Kit RTF-KIT-2 off Buyee Japan (for high-quality OEM retrofit fittings & labels)

-Four Seasons 26744 AND 26745 O-Ring & Gasket Air Conditioning System Seal Kits (26745 has mostly correct O-ring sizes)

-Four Seasons 33412 Filter Drier (slightly smaller than R-12 drier, still fits in bracket)

-FOUR UNCLES IRONCUBE AC Flush Kit

-Four Seasons 69994 Super Flush Solvent qty (2) (3 cans would be better)

-Chemours Brand Automotive Freon R134a Refrigerant - 12oz Can qty (3) (legit Freon-brand Freon)

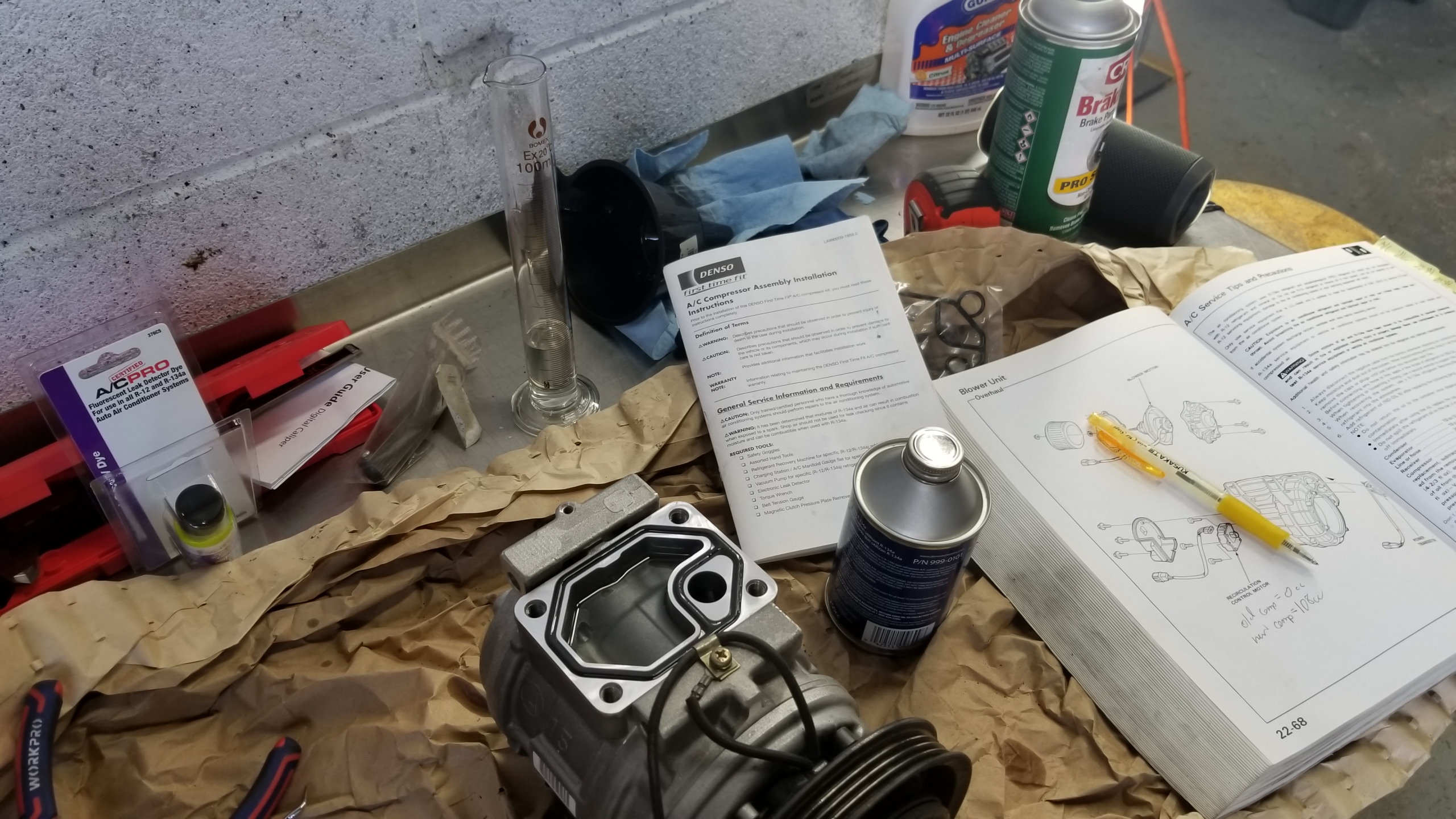

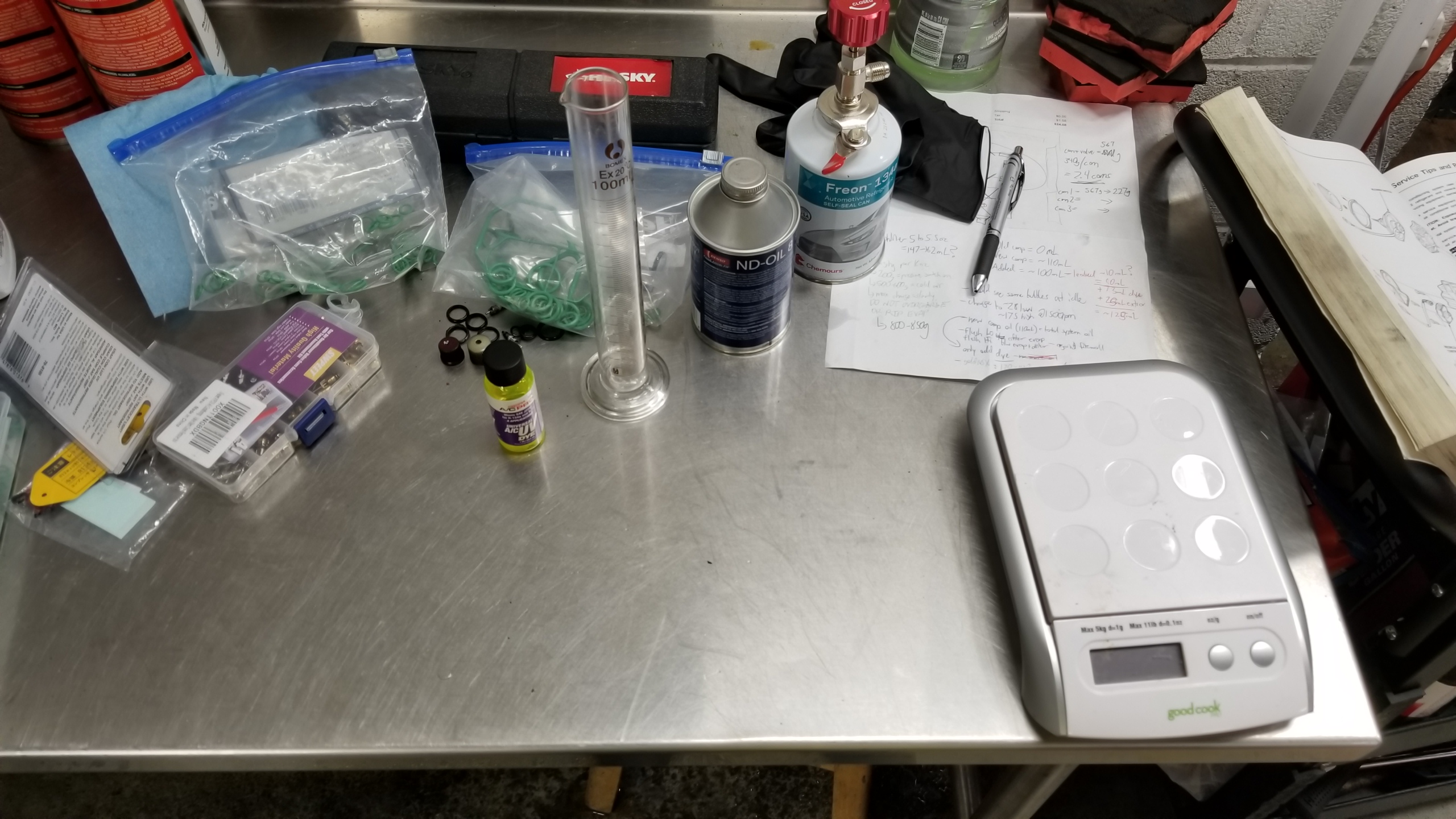

-Denso A/C Compressor Refrigerant Oil 999-0101 (ND-OIL 8)

-Amazon R12 / R134a AC Master Valve Core Repair Kit (need valve core removal tool)

-Amazon AURELIO TECH 2020 UPGRATE Version 4 Way A/C Manifold Gauge Set Kit

-Harbor Freight vacuum pump

-Front A/C condenser pipes A and C (80331-SL0-A02 and 80333-SL0-A03) from ATR Racing (same between LHD/RHD, not available in US)

-100mL graduated cylinder (cylinder with GED acceptable)

-UV flashlight

-UV dye

-tabletop digital scale

-compressed air source

Why did I undergo this process? Number 1, my A/C wasn't blowing much colder than ambient anymore, and was low on R-12 according to the drier sight glass and noticeable lack of colder air on the driver's side (see

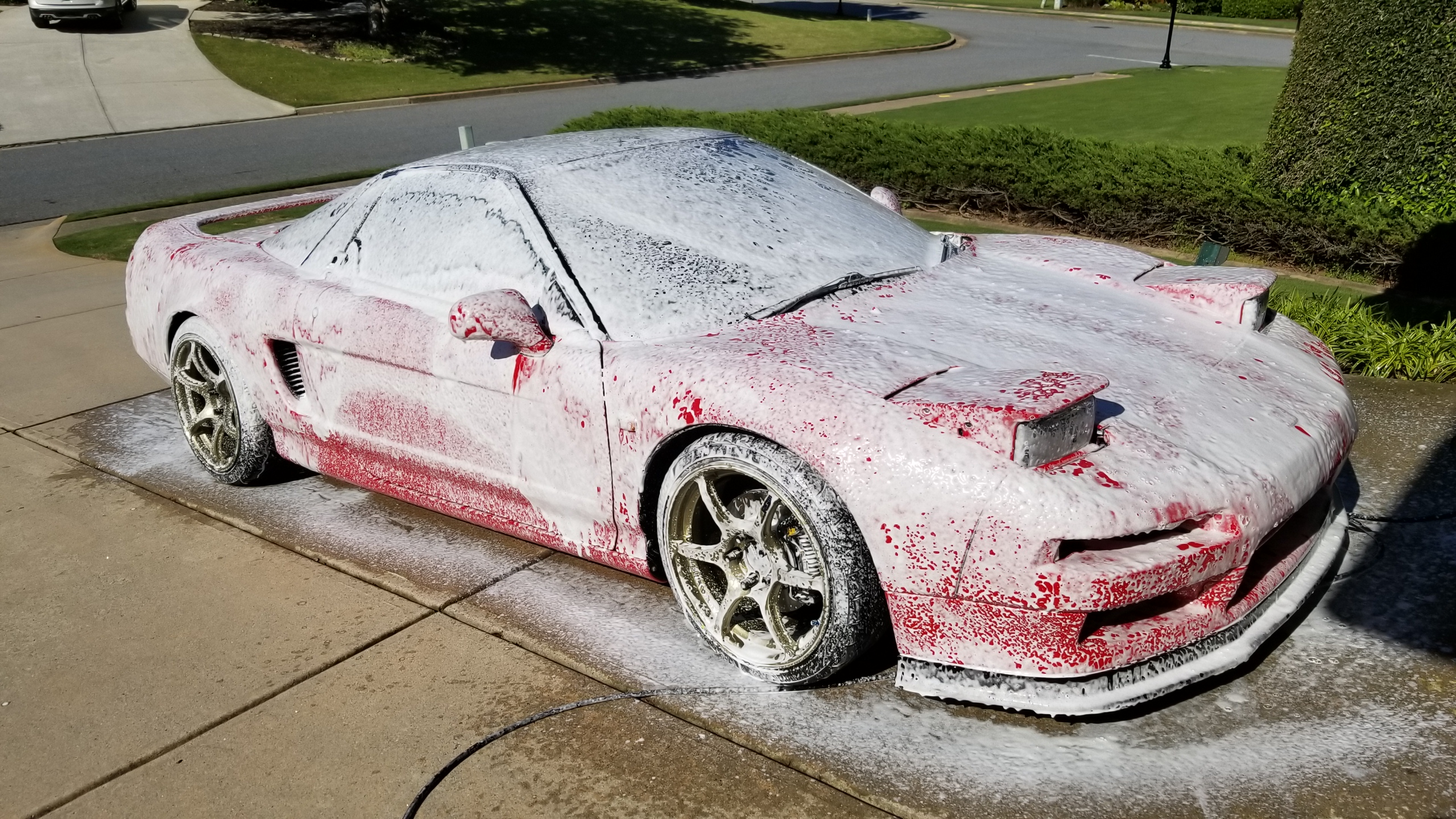

http://www.nsxprime.com/forum/showt...at-the-same-time?p=48762&viewfull=1#post48762). No one works on R-12 anymore, I didn't want to have R-12 anymore, R-12 parts are hard to find, and my A/C compressor was pretty loud with the clutch engaged. I wanted to do a complete flush of the system to make sure the compressor wasn't sending death particles throughout my condensers and evap.

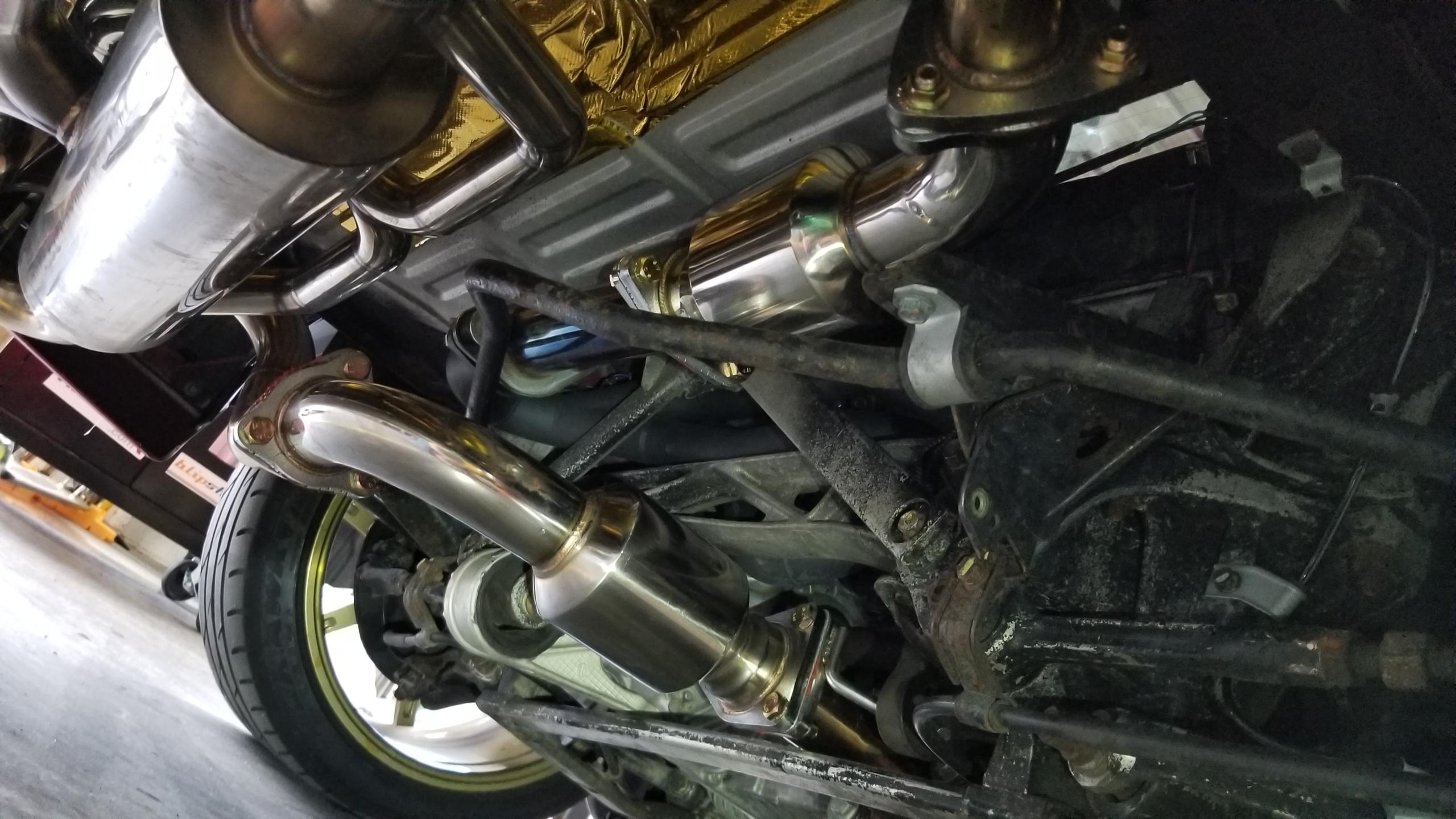

This time I used the 2-post lift for the first time. It takes a lot more positioning and setup to get right, but once I got everything lined up it was so nice being able to stand up and work underneath the car instead of sitting down. I debated a lot as to which direction to lift the car from but this orientation with the asymmetrical lift arms got the center of gravity closer to the middle of the lift.

Here's the new Denso 471-1194. There are a few choices for R-134a compressors from the Kaz thread above. This particular model has a pulley that's too big and will overdrive the compressor, especially with the slightly larger A/T crank pulley I have. This requires re-use of your old clutch set. I went with this model because it was much cheaper than the 471-1193 and did not require buying the updated OEM compressor bracket to shift the pulley over.

It's possible to re-use the old R-12 compressor which supposedly works fine for a while, but if you're doing this job then just pay the extra ~$200 for a brand-new compressor with the correct oil.

At this point it would be prudent to remove the A/C belt and the 10A fuse for the compressor clutch until you're ready to charge the system again so that the compressor doesn't automatically kick on when you have no or low refrigerant.

Obviously you have to remove the old compressor as well, which I didn't happen to get any pictures of. If you're familiar with the car you'd know that it involves dropping the front beam w/engine mount which involves a few steps of removing some underbody bracing, shift cables, A/C wiring connector, and the belt. As usual, the hardest part is getting the through-bolt and nut off the front mount and back on during reinstallation. Usually requires a creative combination of extensions and swivels.

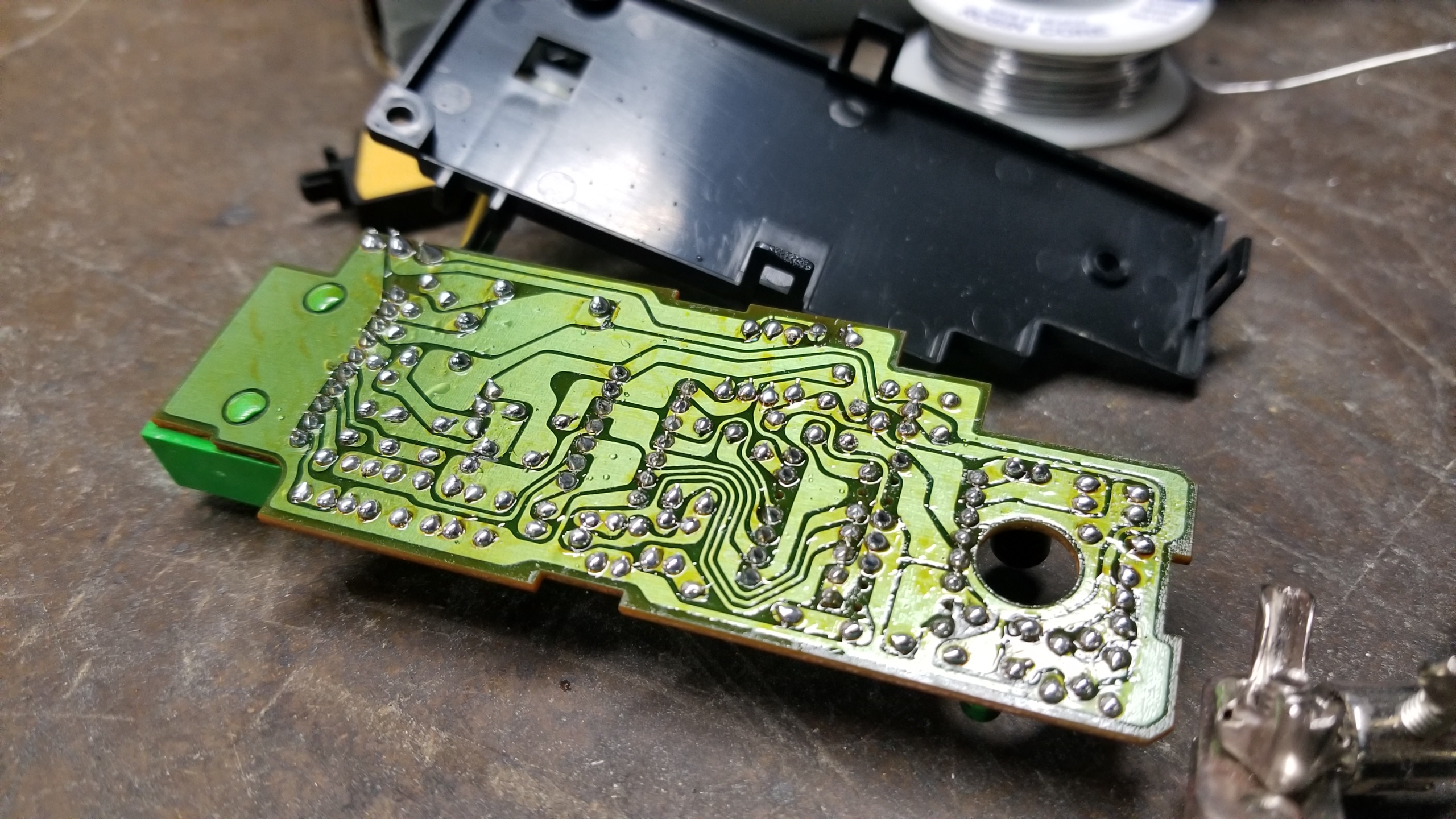

Here's what a new clutch set looks like. No special tools required for disassembly, but an impact for the 10mm center bolt is helpful.

Here's the clutch connector that's integrated into the field coil. This isn't the correct one for the car as shown further below.

Original A/C clutch connector on the engine wiring harness.

To get the new compressor to fit correctly, you need to transfer over your old pulley, clutch assy, and field coil, which also has the correct harness connector. You can't mix-and-match the coils and pulley as it won't fit right. The main downside was that I also re-used the old pulley bearing as I didn't have a new one on hand. I believe my R-12 compressor had been replaced at some point in the past, so my old bearing and clutch looked to be okay to re-use. If you want to try to replace the old bearing with the one staked into the new pulley, you'd have to be careful and probably use some heat to remove the bearing without pushing on the inner race. It wasn't designed to be removed without damaging the bearing since you can't push out by the outer race.

With the old clutch assy installed onto the new compressor, make sure the clutch gap is set according to the FSM. The old and new compressors should have shims to adjust the gap, verify it's within spec with feeler gauges and adjust as necessary before installing the compressor. Otherwise I'm assuming it won't work.

Transferring over the hoses to the new compressor. I drained about 110mL of oil from the new compressor and was only able to fill about 100mL back into the outlet side without spilling. This is a good opportunity to fill with the correct amount of system oil and UV dye, just not to the suction/inlet side of the compressor since I read somewhere that could hydrolock it.

According to the threads linked above, the compressor is loaded with about the right amount of oil for the system, assuming you've flushed out as much of the lines as you can. The only thing I didn't flush was the evaporator.

First use of the flushing kit. Why is it called Four Uncles? What did each uncle contribute? Many questions remain unanswered.

I was very pleased with these products. The flush gun connects with a quick-disconnect to a compressed air source, which you can then disconnect for a short burst of flushing solution or keep it connected to keep blasting. Just remember to close the shutoff valve before disconnecting the gun or you'll blow your eardrums.

The flush solution I used seemed to work well and evaporated quickly. You use way more than you expect though, so I'd get at least 3-4 cans next time. 2 was barely enough.

Results from flushing the hoses. The black spot in the middle is just leftover paint. Fortunately, the fluid came out very clean, the green tinge is from old UV dye.

New compressor installed and torqued. Not pictured but I tore off the Reflect-A-Gold off the back of my old compressor and glued it onto the new one to help reflect some heat away from the exhaust headers.

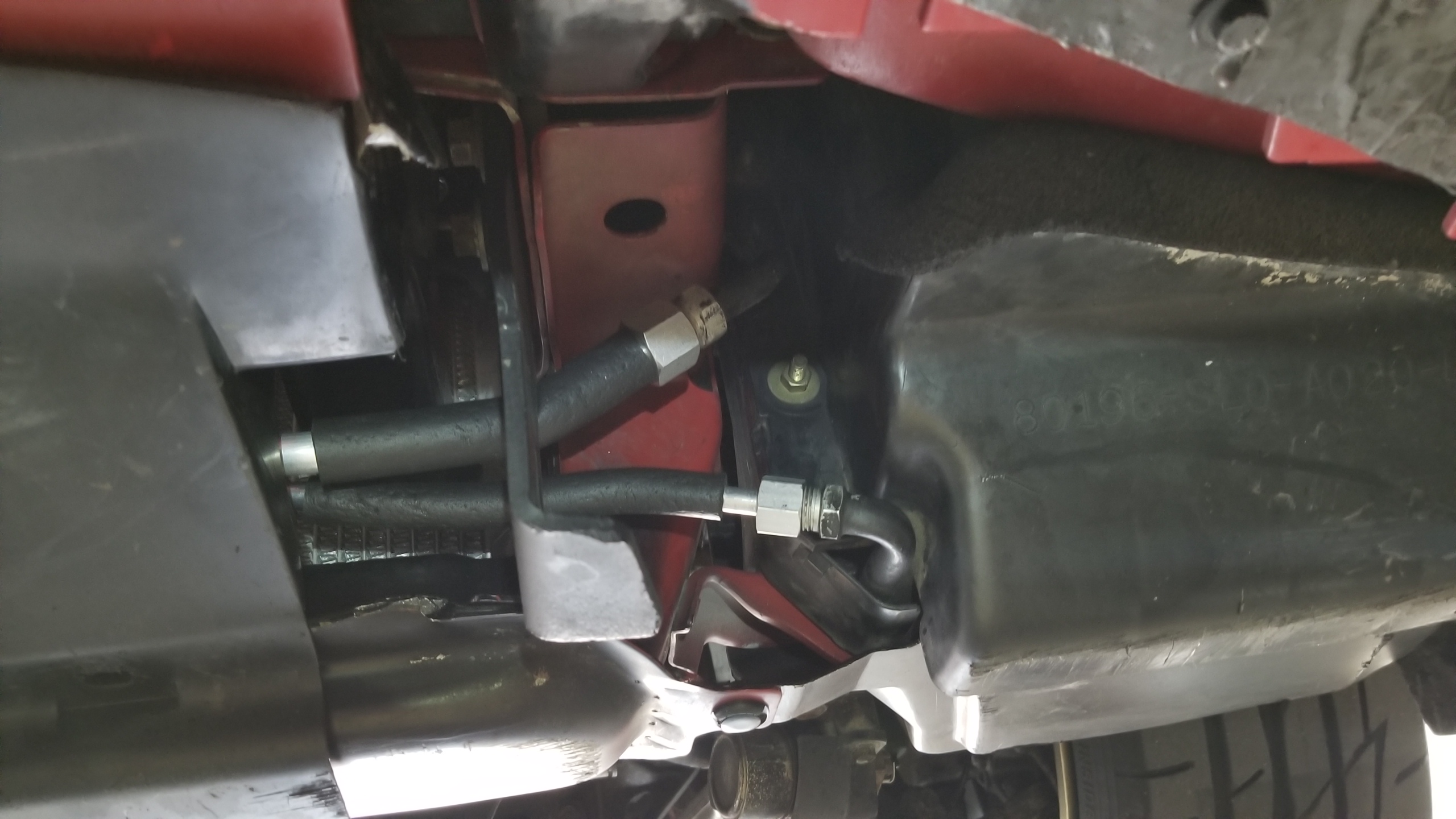

Here's where the compressor hoses connect to, next to the gas tank. Hopefully you caught on that removing these means that you're breaking a line into the A/C system and it needs to be discharged of refrigerant before performing this work.

FYI, it was impossible to find any A/C shops in ATL that still work with R-12. I called 7-8 places including a classic car-specific A/C shop, and none of them work with R-12 anymore let alone have the capability to recover it which legitimately surprised me. Maybe that wasn't the case 5-10 years ago but now I'm pretty confident that there's close to zero professionals that mess with R-12 anymore. I'll say my system was empty when I replaced the compressor and leave it at that. You should make every attempt to recover any refrigerant, R-12 was superseded to R-134a for a reason. Which then was superseded again recently to R-1234yf which is even less of a greenhouse gas, but if you have a newer Civic that uses it then you probably hate it already.

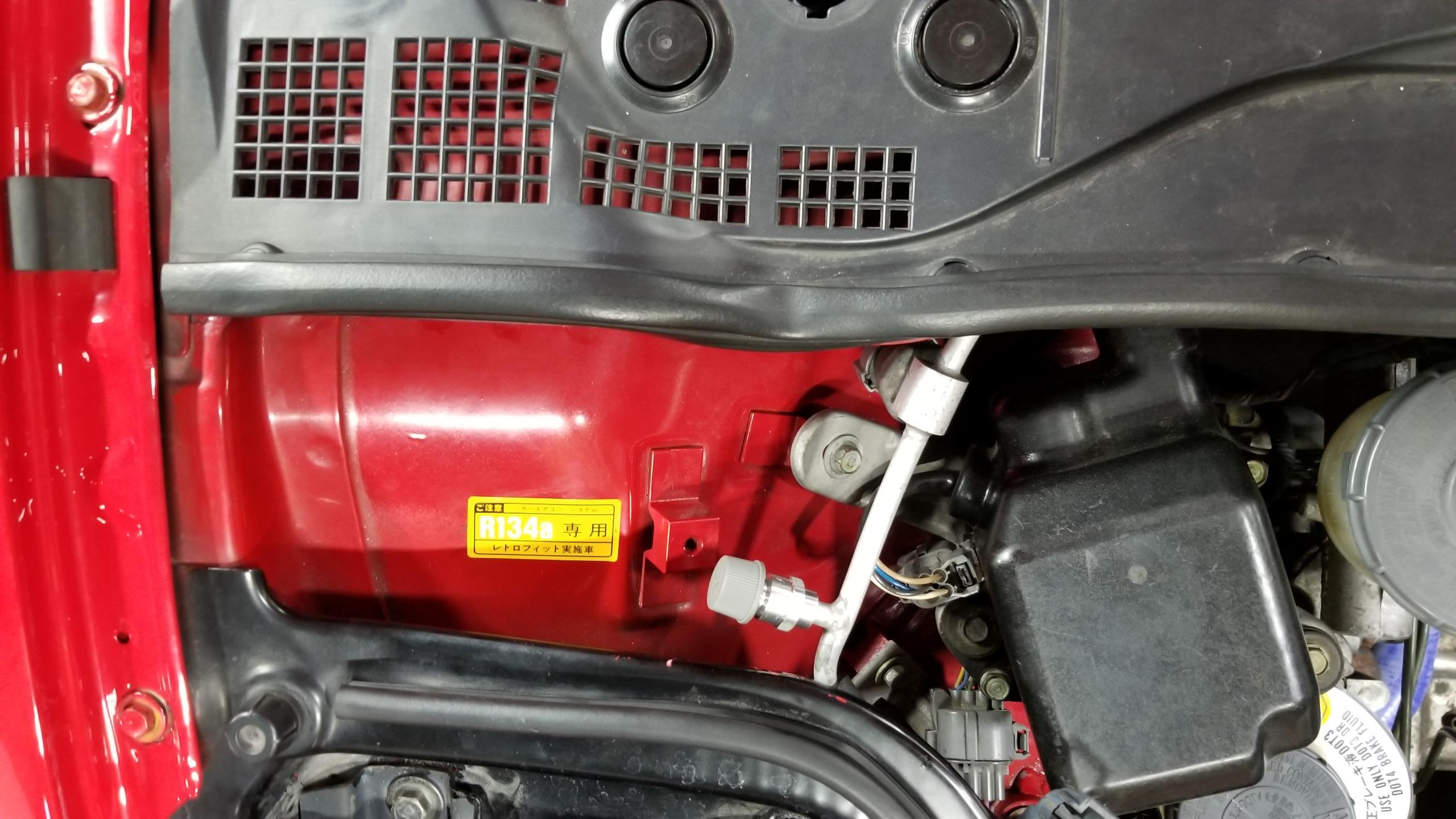

With the compressor replacement done (and the underbody parts put back together), I moved onto replacing the high/low fittings up front with new R-134a-spec ones. The R-12 fittings are externally threaded, R-134a fittings are quick-disconnects with internal threads for the caps. The Denso RTF-KIT-2 was expensive and I had it imported from Japan no less, but the fittings are high-quality and it includes the JDM conversion stickers which I'm a sucker for.

Of course, no A/C job is complete without a Swpeet(??)-brand valve core kit. Really, the only thing I ended up needing was the valve core remover tool, which I used to remove the R-12 valve cores from my existing fittings. This was necessary because the new fittings come with their own Schrader-type valves, so you don't want to double-up on those.

New high-side fitting installed. It just screws on to the old fitting once the old valve core is removed. Very easy, just don't over-torque it.

A bit further up is the pressure switch which you can also replace if necessary, I just left it alone.

Now's a good time to perform a system flush, so below are some pictures of the connection points to look for. Key points are the compressor hoses in back, one fitting under the center tunnel, two fittings at each front condenser, two fittings at the drier/accumulator, and two fittings at the evap front bulkhead.

The FSM climate control section does a good job of explaining the system layout, so study that for a bit and then you'll understand which pipes to flush and where. The 1991 manual is for R-12, but page 22-6 has a great system diagram and pg. 22-65 has all the oil and torque specs for the system fittings. I have a physical copy of the 1994 manual which is for R-134a instead, so keep in mind which one you're looking at especially for the oil and refrigerant charge amounts. The LHD/RHD layout isn't much different, though the evap is handed and some of the front hardlines are too.

For flushing: you'll go through solvent faster than you expect. Flush as many lines as possible, and find a way to capture the dirty fluid on the other side. It would be best to have some polytube to divert dirty fluid to a container, I relied solely on rags to absorb the fluid but that was a bad idea. The velocity that the flush travels ends up splashing it everywhere, and if your system had UV dye in it already it will get on absolutely everything. This added a few hours to my work efforts for cleanup of spilled dye so that I can tell if my new system is actually leaking. Blow out each line with compressed air for a minute or so to remove any leftover fluid. Rubber-tipped nozzles for air guns are necessary.

For O-rings: replace any O-rings with new ones from the kits above, make sure you use the old O-ring and match the size and thickness as closely as possible. Usually the new rings are green, but that's not necessarily true since the new lines & compressor I got have black rings and seals for R-134a. Use a small amount of new ND-8 oil to lube the rings before installation, as usual.

Here's where the drier/accumulator goes. Two fittings, one inlet from the 2nd condenser and one outlet to the evap unit. The bracket has a 10mm clamping bolt that is a bit too big for the new 134 receiver, but you can make it fit. I stuck a small piece of foam between the drier and clamp to make it snug. The R-12 accumulator being larger also allows for more margin of error for the total refrigerant charge, so you might be able to use either one.

New drier part number. This is cheap and should be replaced as well as a consumable item. It comes with new O-rings as well. Don't open up the new drier until you're ready to pull a vacuum on the system so you don't ruin the desiccant with moisture in the air.

Two fittings on the front-right condenser. This is the first condenser that receives the hot/high pressure gas from the compressor and starts turning it into a hot/high pressure liquid.

You should be very careful with these fittings since they sit at the front and take some abuse from debris and corrosion. Everything's aluminum and easy to strip. The larger lines have 22mm fittings and 19mm fittings if I remember right. If you can't get a fitting loose, try some penetrating fluid and/or heat and try again. If you still can't get it loose, it's probably best to leave it alone and let the old O-ring do its job. If you end up kinking or breaking a line to the condenser, you'll have to get a new one and pull the front bumper off to replace it which isn't fun. My front condensers are likely original and fairly beat-up already, but they're still kicking so I'm keeping them as long as possible. Fortunately, I believe LHD/RHD cars share the same part so it should be a bit easier to find a replacement if necessary in the future.

Flushing the condensers take a ton of solvent before any comes out the other side. The first condenser contained a ton of old oil, the second condenser started out much cleaner. Save extra solvent for these and blow out thoroughly.

Same side reconnected after flushing, with new O-rings and a new front hardline between the two condensers.

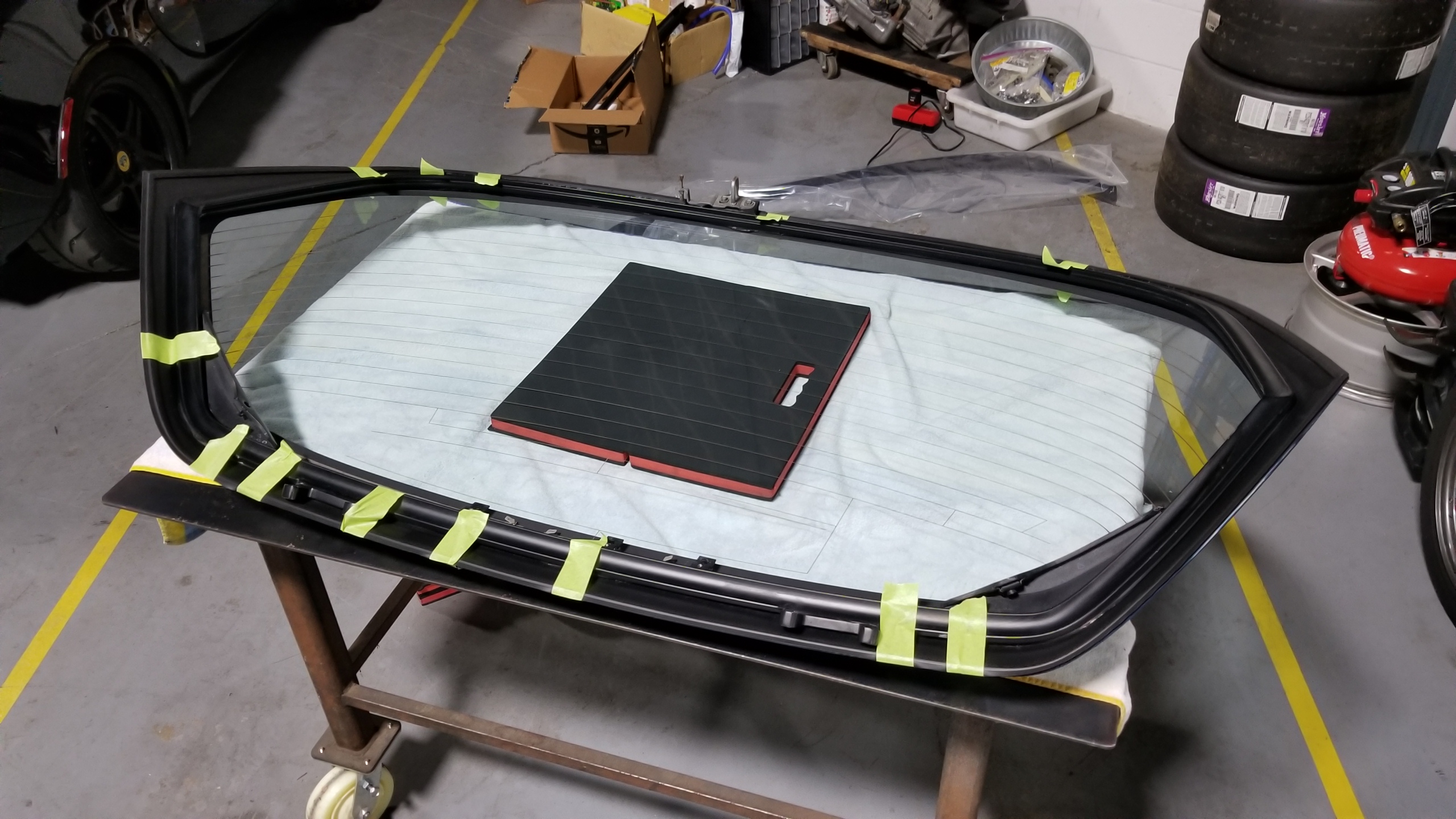

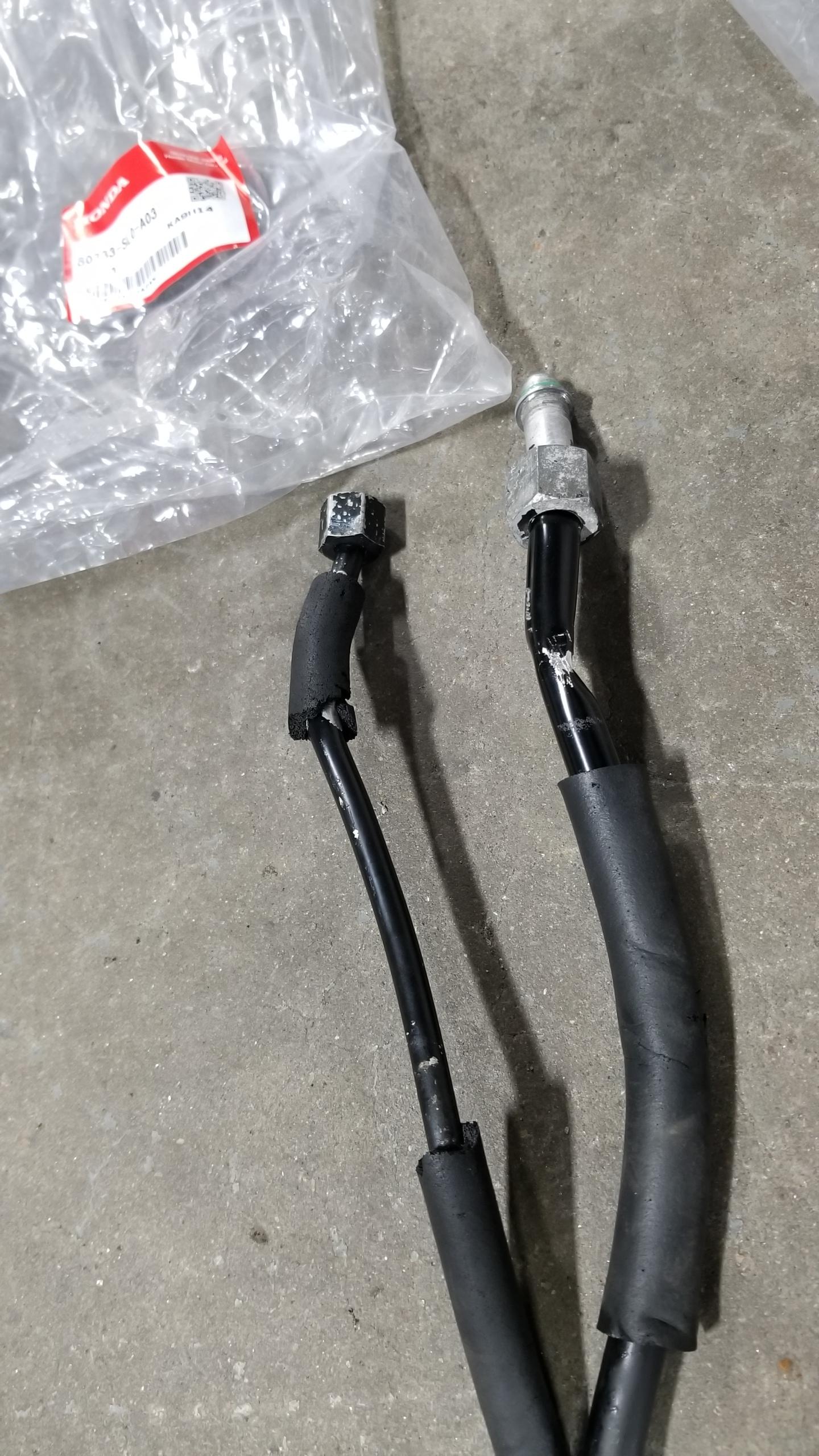

This is the front-left condenser, the 2nd in series. This pic is after I replaced the two lines with brand-new ones since the old ones were kinked and beat-up, also something Kaz recommends. The top line is from the first condenser to the inlet of this condenser, the bottom line is from the condenser outlet to the drier inlet.

There's one fitting on the low side under the center tunnel which runs between the low-side hose and the inlet to the first condenser. Don't forget to replace this O-ring too.

Last but not least, in the background is the low-side fitting and the two pipes to the in-dash evaporator. The two 12mm bolts are not hard to remove, but it's difficult to get enough clearance to remove the lines for flushing to replace the O-rings. Since this is probably going to be the outlet side of your flushing, it would be prudent to make sure the fluid doesn't spray everywhere so you don't have to waste too much time cleaning up. You can remove a few bracket bolts for the high side line to get a bit more free-play to work with.

This is where you'd disconnect the evaporator if you were removing the HVAC blower/heat/evap unit from the dash, which I'm not doing at this time. Ideally you'd inspect the evap and expansion valve and flush/replace O-rings on those but not strictly necessary and that job alone would probably take several days.

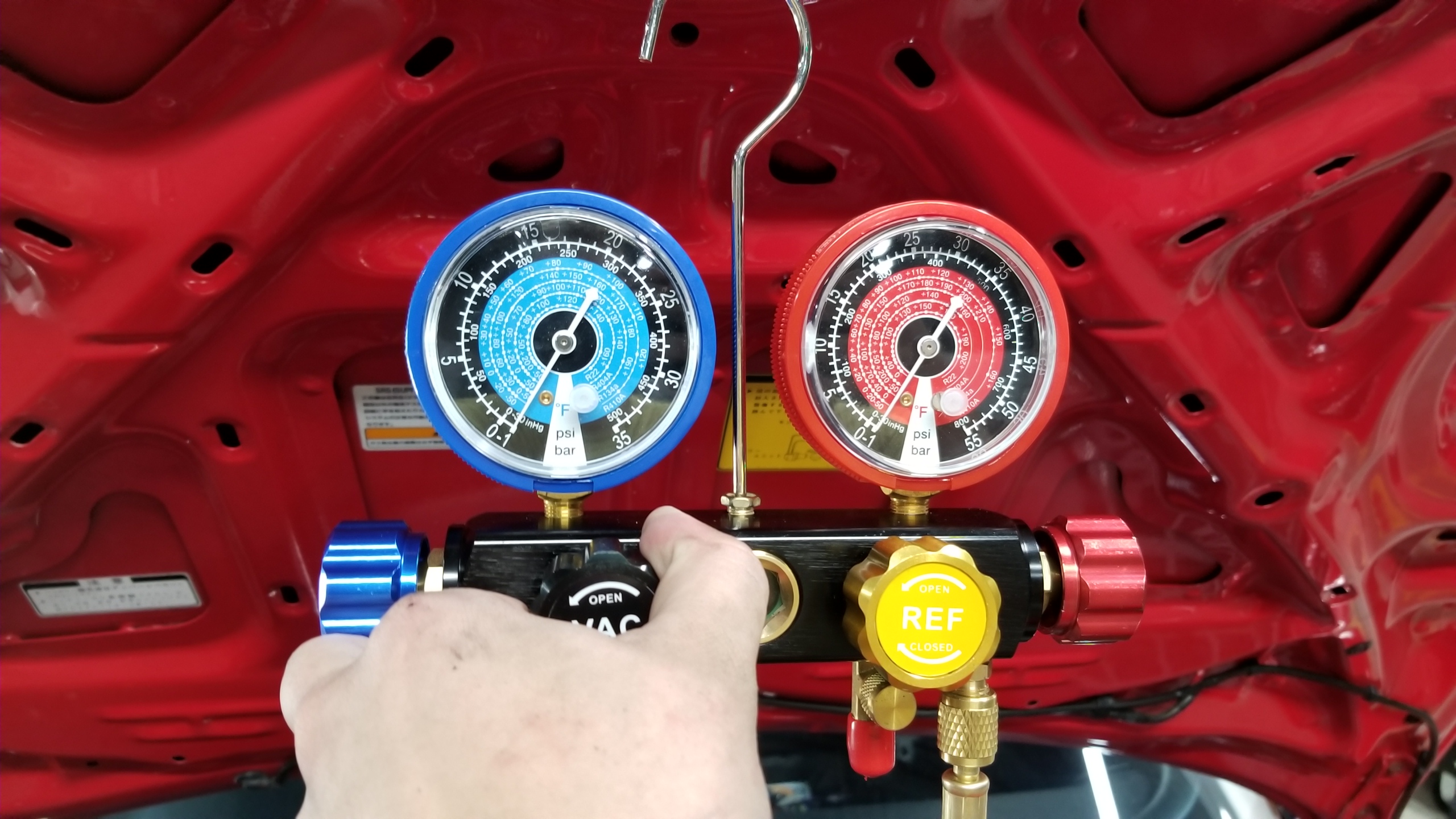

Once I had done the laborious and dirty work of flushing all the lines and replacing as many O-rings as possible, then I finally connected up the manifold gauge set and vacuum pump, and installed the new drier/accumulator. Right after that, I turned the vacuum pump on to pull out air & moisture from the system to preserve my new drier.

I was pretty impressed with the manifold gauges I got for pretty cheap on Amazon, it seemed of decent quality and also had separate fittings for the vacuum side and charging side which was convenient. I watched a few different videos on this process to make sure I hooked up everything correctly and didn't do anything dumb. It's not hard to do, but easy and potentially costly to mess up.

I opened up both the high and low sides to pull vacuum, shown by the 0-30 inHg pips on the gauges which aren't the most clear. Anyways, I had the vacuum pump on for about 20 mins and then shut off the system to check for leaks by seeing if it lost vacuum over time. After another 20 minutes or so the gauges hadn't changed at all so I called it good to go.

After I pulled vacuum on the system, it actually took me another 1.5 weeks to get to this next part which was replacing these two lines below and charging the system. I ended up finding that the front two lines were kinked up in a few places, and that kind of pressure drop is not good for overall system efficiency and might flash some of your liquid refrigerant from the condensers back into gas prematurely of the expansion valve.

Predictably, these lines are all but unavailable in the US, either backordered or maybe discontinued though Tim @OEMAcuraParts was able to find one of them on a shelf somewhere, but I needed both. Amayama was my next choice, but one of the lines was on 1-3 month backorder which I didn't want to wait for. Fortunately, Christian @ ATR being the king of parts had both in stock and at my door in about a week. The lines were quite a bit more expensive than the new compressor itself but you gotta do what you gotta do. The lines come capped with new O-rings, which happen to be black, not green. I used them anyways, color isn't really an indication of material and I'm sure they're 134 compatible.

I disconnected the old lines and was pleased to find the system had held vacuum the whole time. Fitting the new lines was challenging, both to snake the old ones out and new ones in place, but especially to line up the fittings correctly so that the O-rings were square and I didn't cross-thread any nuts. Some "gentle but firm" muscling into place was required.

Kinky, but not the fun kind. Part of this was my own fault with the prior curb incident..

Once the new lines were installed, I prepared to charge the system, which I of course got nearly no pictures of performing. Shown is the new can & adapter, and a kitchen scale for measuring the refrigerant.

This part will largely be text since I was focused on not messing up, but here's the rundown of charging new refrigerant:

-R-134a charge amount is 800-850 grams, a bit less than the R-12 amount. Refer to 1994 FSM. Apparently, overcharging the system can puncture the evaporator, which is a massive undertaking to replace

-pull vacuum for at least an hour, longer is probably marginally better

-close off high side, charge only through low side fitting

-connect yellow charging hose and bottle. Any UV dye or extra oil required can be poured, slowly and messily, into the hose as well to be sucked up into the system. Better to pour it into the compressor or into a line instead IMO

-reconnect A/C compressor and 10A fuse, turn on car and turn on A/C on CCU

-open up the can and manifold charge valve, wait for Freon to come out, wonder why it's not coming out, realize the can tap valve has a very small range where it's actually opening the can, purge the hose of air through the manifold Schrader valve without letting oil spray out, realize you should invert the can slightly to get liquid to come through, but not too much liquid since the compressor isn't meant to compress liquid and you could damage it so try to keep the can upright to pull in gas which is much slower to come out. The can gets really cold as well because of the flashing refrigerant inside

-charge two full cans of refrigerant, 340 grams each for 680g total. At this point, the A/C compressor should've kicked on, and you should be getting noticeably cold air

-VERY CAREFULLY, charge with about half of the 3rd can to hit the 800-850g range (others have said 850-900g, I'd prefer to be lower). It pays to take it very slow here and try to keep the can upright and pull in gas only, which is slower but safer. I disconnected the can several times to check the weight on the scale, if you have the hose connected, it will mess up the scale reading. Make sure you take the weight of the can itself and the valve into account

-hit 800g verified by the scale (aiming for the lower end to be safe), disconnect everything and you're done. Enjoy ice-cold air

I didn't pay much attention to the sight glass or manifold pressures while I was charging, I just aimed for the right weight of refrigerant. My high/low side pressures seemed good at the end, apparently expect ~30 psi low and ~177 psi high, depending on engine RPM and ambient conditions. The sight glass remained foamy looking which I've read is to be expected with 134.

I'm sure I missed some steps, but there's plenty of videos online of varying quality since charging R-134a is common to pretty much anything. The keys here are not to charge over 850g, make sure you have the right amount of oil, and make sure you're not charging into the high side fitting or pulling air into the system accidentally.

JDM AF tag with the amount I charged into the system below.

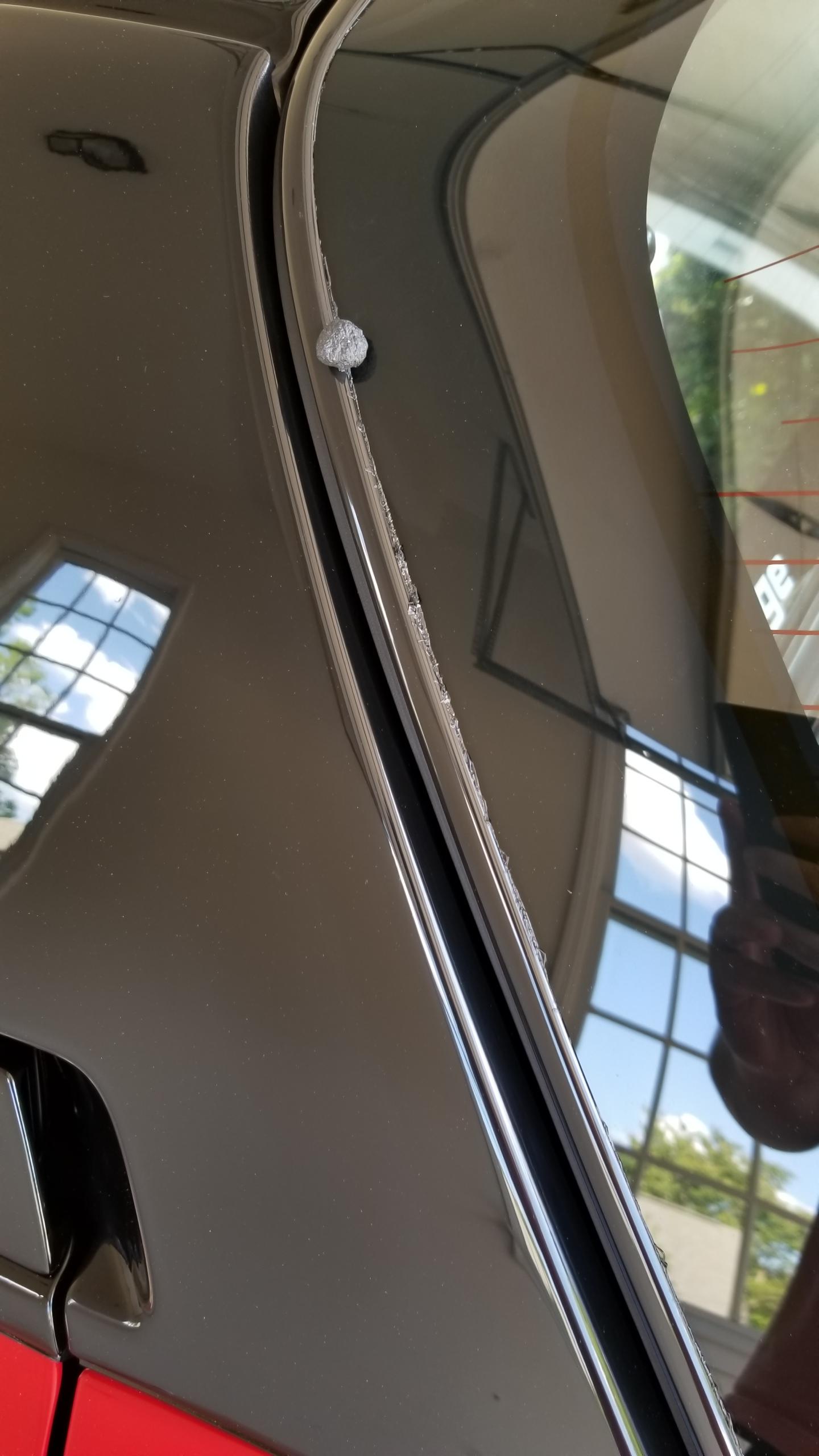

R-134a conversion label affixed next to the high side port, the front radiator support didn't really have room and I didn't want to put it on the underside of the hood, so this seemed like a good compromise.

Somewhat anticlimactic ending since I can't convey temperature through the internet, but rest assured, from a brief test drive I was thoroughly chilled and very happy. It was an incredibly humid day in GA as evidenced by the huge trail of condensation I left behind wherever I drove. I still need to test whether the A/C compressor actually shuts off, and will update if anything doesn't work or something breaks, but I did everything I can think of to make this last as long as possible and feel good about it. Of course, at some point I'll have to tear into the HVAC core and evap but hopefully not for a long while.

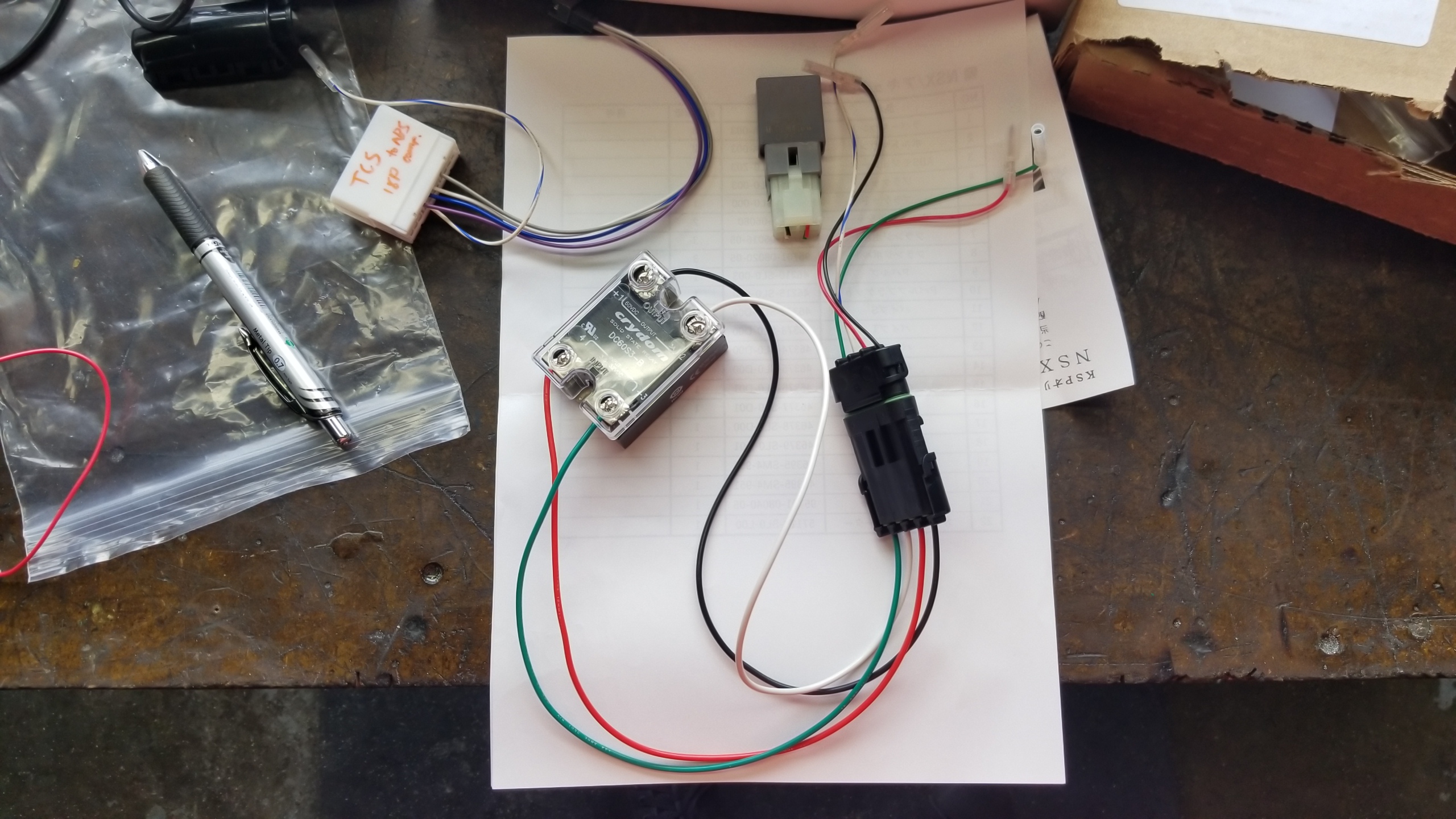

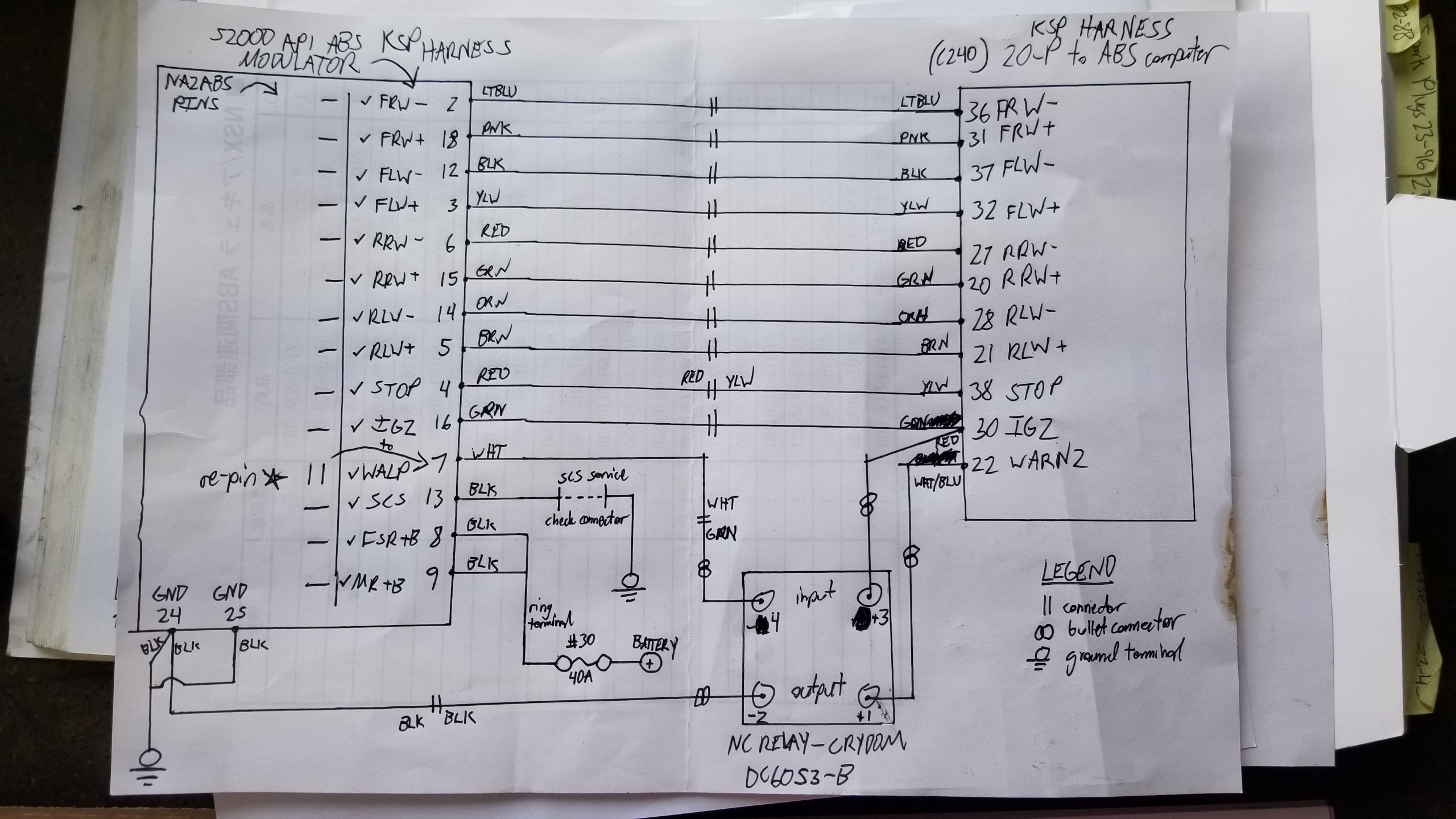

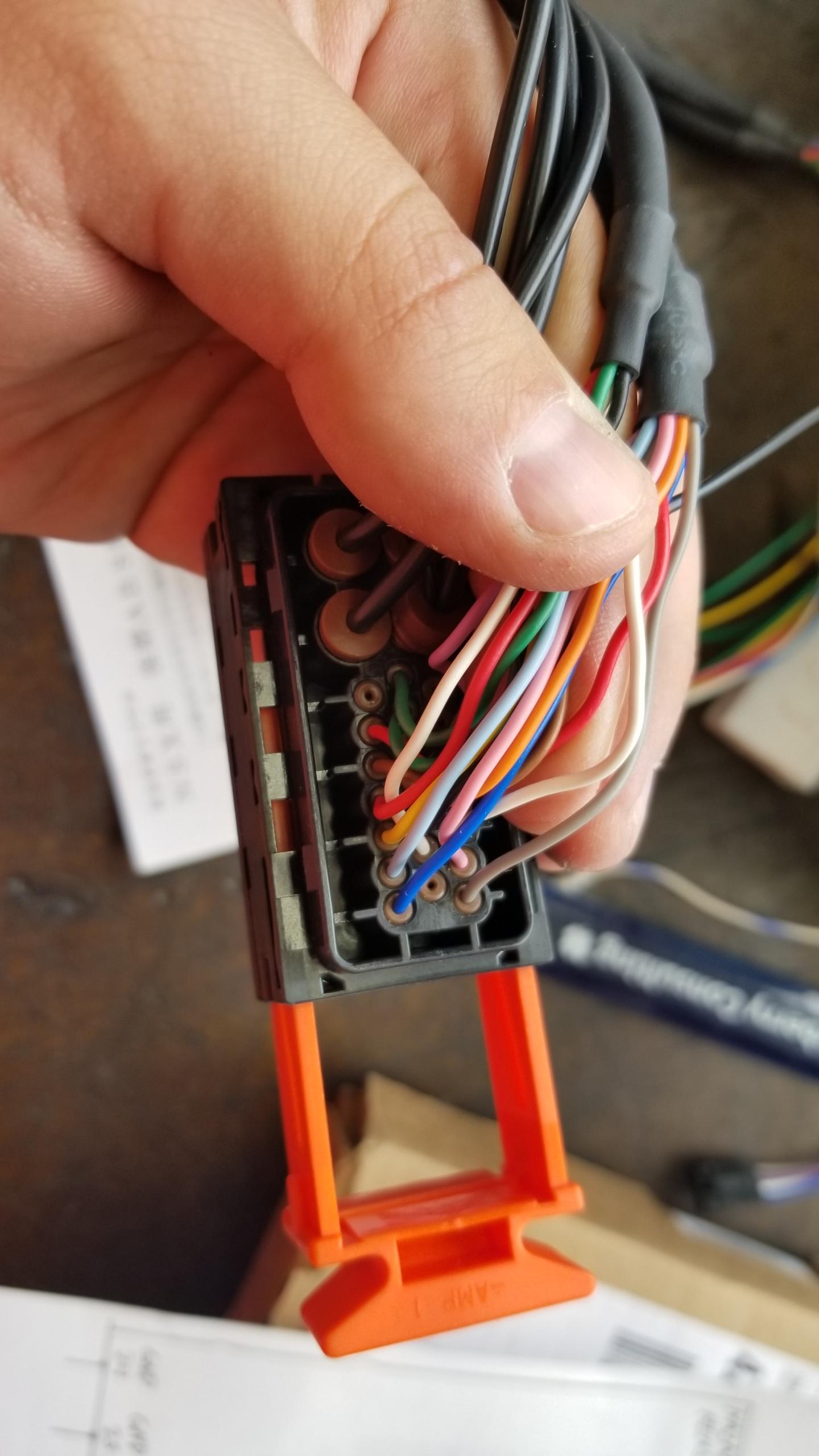

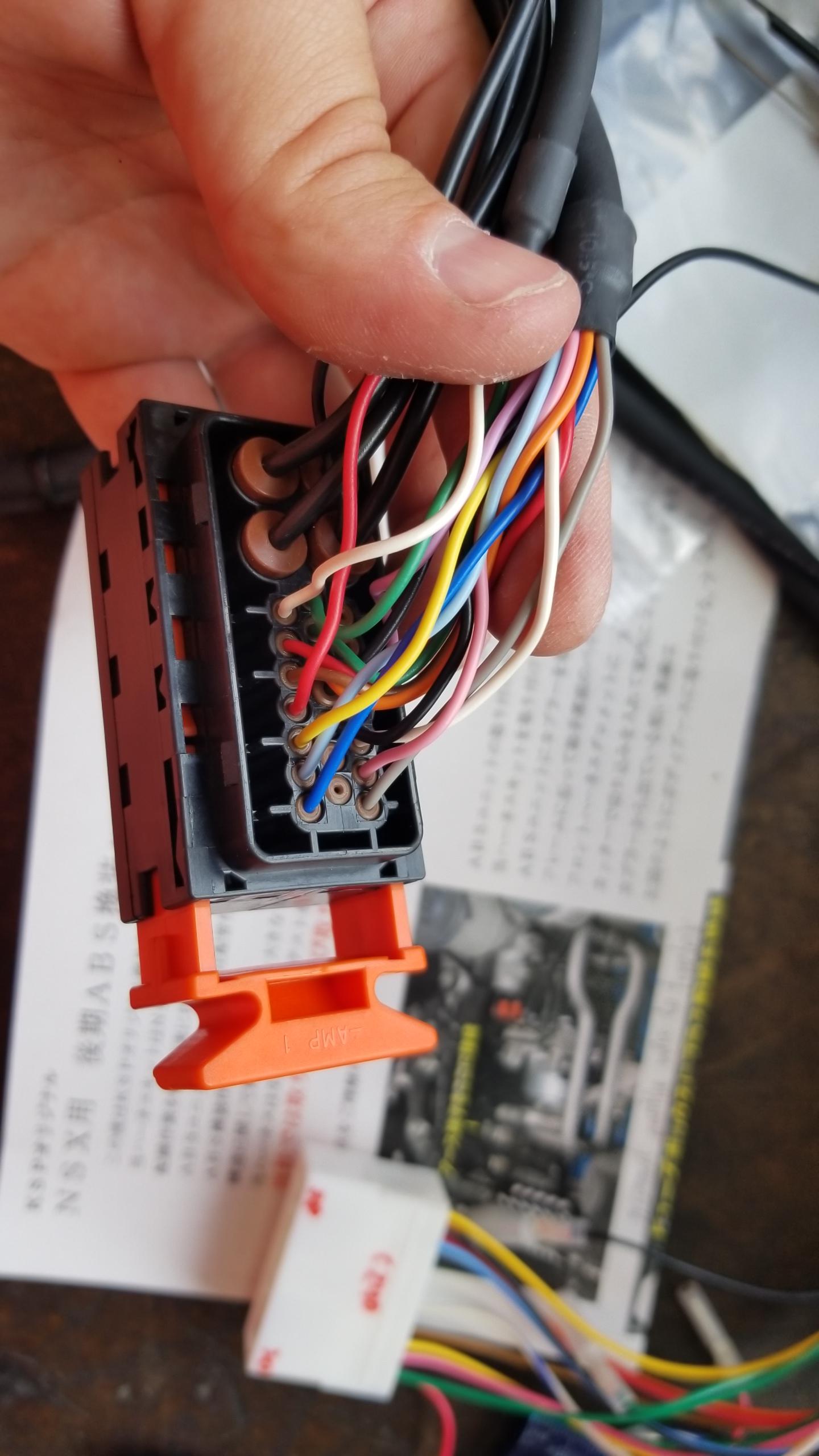

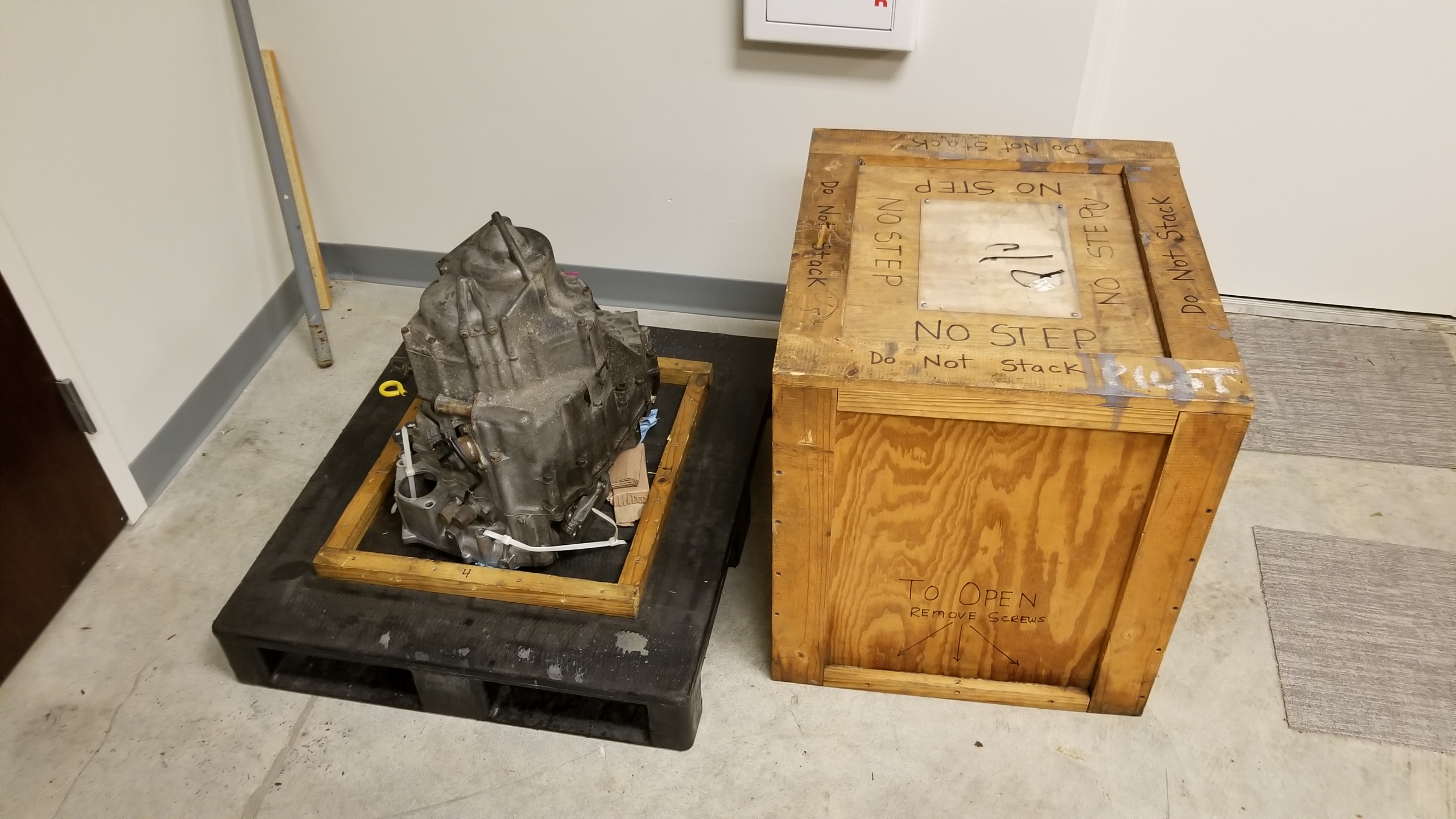

Future projects include the S2000 ABS swap which I've been sitting on for months, but I figured my A/C was more important since I was concerned the compressor was being damaged. So I finished that just in time for fall to roll around :biggrin:. I also have to replace my rear-left ABS sensor since it seems to be going out, and both my outer driveshaft boots since I ended up tearing small holes in them when I removed the OEM rear coilovers because the springs shoved the strut against the boots, should've used spring compressors. End post.

. This was the point I was worried about getting to in case I found a horror show underneath from prior damage. Fortunately I really didn't see any signs of damage up here, it had certainly been removed before somewhat carelessly but that's it. One of the bumper foam spring clips was missing and one tab on the bumper was broken, and some clips/screws were mismatched, but not bad for 31 years.

. This was the point I was worried about getting to in case I found a horror show underneath from prior damage. Fortunately I really didn't see any signs of damage up here, it had certainly been removed before somewhat carelessly but that's it. One of the bumper foam spring clips was missing and one tab on the bumper was broken, and some clips/screws were mismatched, but not bad for 31 years.