Question for the AC pros. Rebuilt climate system on my 91. New Evaporator, new condensers, new dryer, new expansion valve and new compressor. NEW. ;-) I have gauges and a vacuum pump. Held vacuum for 30 minutes, so no leaks afaik.

I added 34oz of R134. Realized almost immediately that BOTH of my condenser fan motors were shot. Replaced them both. Also, CCU has been re-capped and appears to work fine. I may have inadvertently overfilled since I think you use less R134 than r12, right?

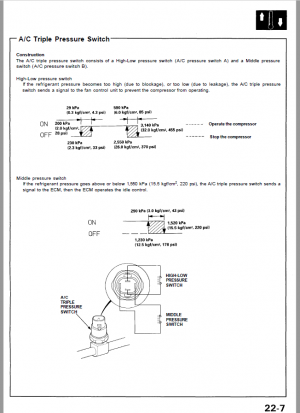

When I fire up car and turn on the AC it blows nice and cold for about the first 5 miles of my drive then it goes warm. Any idears? I dont recall the service manual having detailed expected pressures when operating for high and low side...

Found this in another thread, did I overcharge?

Then R-134a

NSX A/C 134a charge weight.

1.9 lb; 0.85 - 0.90kg

28.2 - 30oz

27-28 low side 179-175 high side

If so, how would I pull some refrigerant out... or can I..... Is stopping to cool after a few miles a symptom of overcharging?

Chris.

I added 34oz of R134. Realized almost immediately that BOTH of my condenser fan motors were shot. Replaced them both. Also, CCU has been re-capped and appears to work fine. I may have inadvertently overfilled since I think you use less R134 than r12, right?

When I fire up car and turn on the AC it blows nice and cold for about the first 5 miles of my drive then it goes warm. Any idears? I dont recall the service manual having detailed expected pressures when operating for high and low side...

Found this in another thread, did I overcharge?

Then R-134a

NSX A/C 134a charge weight.

1.9 lb; 0.85 - 0.90kg

28.2 - 30oz

27-28 low side 179-175 high side

If so, how would I pull some refrigerant out... or can I..... Is stopping to cool after a few miles a symptom of overcharging?

Chris.