In order to get liquid to flow down a tube, there has to be a positive pressure differential between the inlet and the outlet of the tube. In this case, the outlet in the jerry can is fixed at atmospheric pressure so you will always measure a pressure at the FPR discharge port that is something above atmospheric. You can never reduce the pressure at the outlet of the FPR to 0psi (atmospheric) as long as you have any kind of tubing attached. What you want is to reduce it to the point that it does not cause a problem for your FPR. 1.7 psi is something more than I would have expected; but, if you have a mungo huge fuel pump that back pressure may be a side effect of a pump with way too much flow.

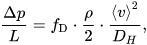

This is the empirical formula for pressure loss in a straight section of pipe of length L. Delta p is the pressure drop, Fd is a fudge factor,

is the fluid density, v is fluid velocity and Dh is pipe diameter.

Notice three things. When you increase L pressure drop increases (if Dh and v stay fixed). When you increase Dh you reduce the pressure drop if everything else stays the same. But, if you reduce velocity you get a pressure drop equal to the square of the velocity. If flow rate stays fixed the v drops by 1/D^2 so increasing pipe diameter reduces pressure because of lower pipe wall friction and lower fluid velocity - a two for one benefit. If you cannot increase the diameter or length of the pipe the only path to reducing the pressure drop is to reduce v which means reducing the flow rate. Because of the squared effect small drops in flow rate equal large drops in pressure.

The flip side to this is that small increases in flow rate equal larger increases in back pressure. If back pressure is an issue, putting in a higher flow rate pump is definitely a bad thing to do.

Note that the preceding formula is for a straight piece of pipe. Add in all the bends that the OEM return pipe has and you have additional restrictions that are not factored into that formula.

Before going down this rabbit hole, you need to confirm that the back pressure on the regulator is causing your control pressure rise. That means that you need to measure pressure directly at the inlet to the regulator and the pressure at the discharge port. Repeat the experiment that you just completed with different sized outlet hoses. Compare inlet / control pressure versus outlet pressure to determine whether outlet pressure is affecting control pressure. If you find that control pressure goes up in direct relationship to discharge port pressure then doing something to reduce the back pressure on the return line piping should have some benefits. If you decide that you want to modify the return line piping, this data will give you some guidance on how big you have to go to achieve a reduction in back pressure. Keep in mind that your test measurements into the jerry can are pretty close to a straight pipe so you will have to adjust up to compensate for all the nasty bends if you follow the OEM return line path.

It seems clear that whatever pump you are using is generating enough flow to create some significant pressure loss in all the fuel system piping. This probably means that if you are measuring the pressure at the fuel filter, their is measurable head loss between the filter and the inlet to the FPR. That is why I recommended measuring pressure directly at the regulator input. I recognize that given the configuration of the OEM fuel rail / regulator this will be very difficult or very expensive and maybe not worth the effort.

So your options are:

- based upon your experimental results, you can try to reduce regulator back pressure by up sizing your return line. As long as you continue to measure fuel pressure at the fuel filter location you are likely going to see some (smaller) pressure rise at idle because of the pressure drop between the filter and the fuel pressure regulator

- you can throttle the fuel supply to reduce flow rates. This could mean a lower flow rate pump or the switchable NSX fuel pump resistor or both. The OEM NSX has both a smaller pump and the throttling resistor and maybe pump size and switchable resistor was the path to maintaining stable pressures with the OEM sized fuel piping.

- Stop obsessing about it.

@bogle is probably correct

I still think the fuel pressure drop is probably normal. I can’t imagine a dumb spring in the FPR would be able to keep the pressure perfectly stable no matter the flow rate.

and the fuel pressure drop is a non issue. I also am inclined to support this view with the provision that the fuel system is maintaining the target control pressure at maximum engine load. If the pressure rise at lower engine loads causes the AFR to drop below target let closed loop fuel control fix that problem - that is what it is there for. The AFR error caused by a 3-6 psi increase in a base pressure of 60 psi is going to be small and will always be on the safe side.

I think you have created this apparent non problem for yourself with an oversized fuel pump. I would be inclined to tell your tuner that the fuel pressure problem is fixed. Disable the fuel pressure measurement in the Infinity and if need be remove the fuel pressure sensor so they can't see the pressure and then tell them to fix the front - rear AFR unbalance at high engine load which I think is more of a real problem. At the point they get the front - rear unbalance problem fixed you can go back to monitoring fuel pressure.

As a final kick at the can, I still think that closed loop fuel control at low load transitioning to open loop at high load is a much safer strategy. I have had wide band sensors go the path of gradual failure. If they start skewing to cause the fuel mix to run lean at low engine loads the risk of engine damage is minimal. You can run AFRs over 18 at idle and low engine load without damage issues (you will likely have performance issues). If they start skewing to cause the fuel mix to run lean at wide open throttle all that unburnt O2 hitting hot aluminum pistons will literally light the pistons on fire = bad. If you normally require +17% fuel correction at high engine load and your O2 sensor decides to check out while you are doing a full throttle run you could be looking at some pretty serious engine damage.