We've been hard at work for awhile now, working on a twin turbo setup for the NSX J swaps. The benefits of the J series are many, mainly being cheap and plentiful replacements, they are outlined in other areas and wont be covered here in detail.

Velocitized's mount systems are being utilized, with a custom crossmember similar in construction with our chassis braces to open up even more room in the NSX engine bay.

The goal is a bolt-in turbo system for those choosing to go the J swap route, without losing anything NSX specific, except the C series replacement cost.

Heres where we sit as of now:

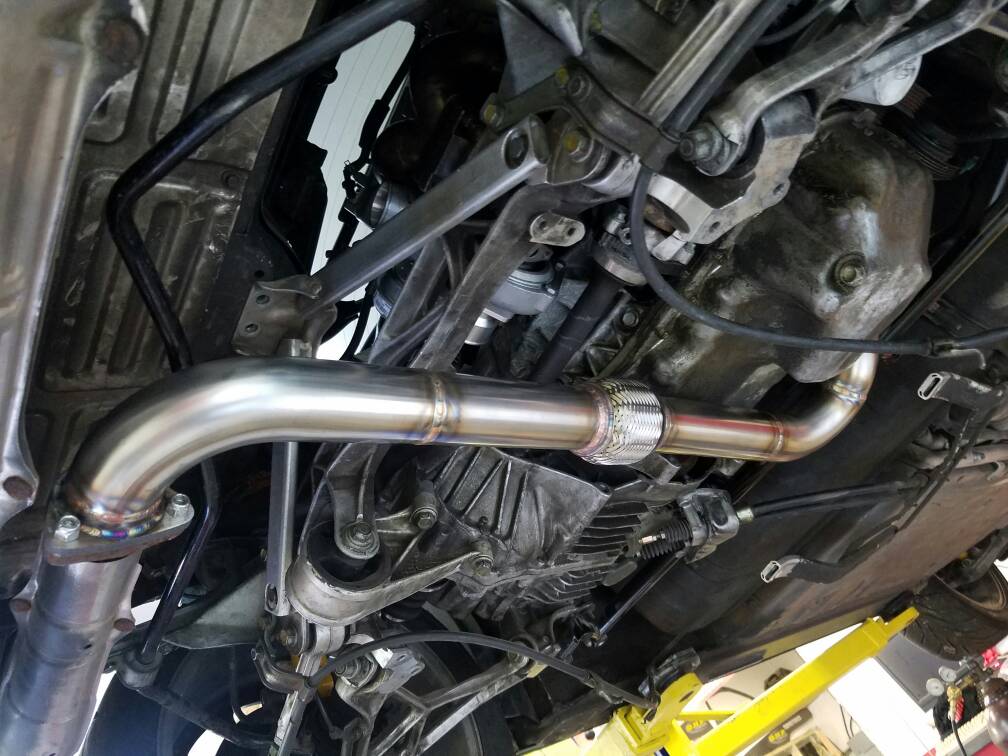

The system is centered around two Garrett T28 Turbochargers(variants available depending on customer goals) with a LoveFab water to air intercooler. Exhaust, and cold side plumbing is being kept to an absolute minimum for cost, as well as transient response.

We transported a customers 1995 NSX this past weekend, to get started on the full conversion. The car is actually our first shop car from a decade ago, which served as our testbed for our C series turbo systems. The symmetry of new frontiers is fantastic!

Anyway, the car suffered a first-of-its-kind broken rod, and the owner decided to swap to the J series for future reduced operating costs. In this case, he chose the J35A3.

We are equipping the car with a LoveFab AEM Infinity5 dbw system to utilize all of the failsafe and traction control options, which will insure a safe and powerful engine and chassis operation.

The only engine modifications will be valve springs/retainers, to rev a little higher, and for safely maintaining valve control while under boost pressure. Previous turbocharged J series experience has shown massive amounts of torque in relation to the relatively low boost levels.

We plan on pushing around 10psi to the J35A3, which should yield an easy 350ftlbs of torque, with over 400whp on 92 octane.

More to follow, as we move forward with the installation of the engine, turbo system, and other subsystems...

Velocitized's mount systems are being utilized, with a custom crossmember similar in construction with our chassis braces to open up even more room in the NSX engine bay.

The goal is a bolt-in turbo system for those choosing to go the J swap route, without losing anything NSX specific, except the C series replacement cost.

Heres where we sit as of now:

The system is centered around two Garrett T28 Turbochargers(variants available depending on customer goals) with a LoveFab water to air intercooler. Exhaust, and cold side plumbing is being kept to an absolute minimum for cost, as well as transient response.

We transported a customers 1995 NSX this past weekend, to get started on the full conversion. The car is actually our first shop car from a decade ago, which served as our testbed for our C series turbo systems. The symmetry of new frontiers is fantastic!

Anyway, the car suffered a first-of-its-kind broken rod, and the owner decided to swap to the J series for future reduced operating costs. In this case, he chose the J35A3.

We are equipping the car with a LoveFab AEM Infinity5 dbw system to utilize all of the failsafe and traction control options, which will insure a safe and powerful engine and chassis operation.

The only engine modifications will be valve springs/retainers, to rev a little higher, and for safely maintaining valve control while under boost pressure. Previous turbocharged J series experience has shown massive amounts of torque in relation to the relatively low boost levels.

We plan on pushing around 10psi to the J35A3, which should yield an easy 350ftlbs of torque, with over 400whp on 92 octane.

More to follow, as we move forward with the installation of the engine, turbo system, and other subsystems...

Last edited: