-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Where is your oil pressure gauge after engine start?

- Thread starter apu8883

- Start date

What do you call MAX? Thats 80PSI on the gauge. With a cold engine oil pressure at start up idle mine may read as high 50-60PSI but never seen it go higher than that. At normal operating temp the gauge reads 20PSI at idle.

What weight oil you running? Has it always been that pressure at cold start?

What weight oil you running? Has it always been that pressure at cold start?

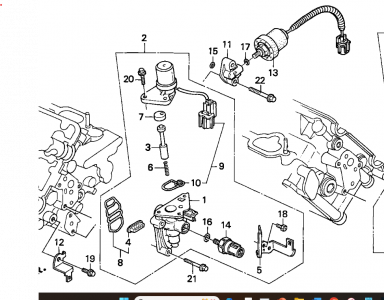

FWIW SoS makes an oil pressure sender relocation kit that comes with a new sender, and is cheaper than oem. I have had it for a couple years without issue

Yes, its buried down in there under the VTEC solenoid, you'd probably have to pull the reservoir to do it from top . Be sure you can return the item if its as simple as a broke wire, or, God forbid, a problem with the ECU. If you can confirm its the sender first you can probably get one for half that price from Amayama in Japan.

The ECU is not associated with the oil pressure gauge circuit so no need to sweat that particular bullet.

According to the SM, the resistance of the sender goesup down as the oil pressure increases so an open circuit or a bad connection in the gauge circuit will cause the gauge to read 0 or low oil pressure. A worn wire allowing a short to ground would result in a high pressure reading; but, it would tend to stay high. The SM does not provide a resistance test value for the pressure sender. Unless @Heineken has sender test values from the development of his most excellent cluster tester there is no way to do that type of test on the gauge or the sender.

If after start up your oil pressure reading returns to a more normal value something else might be up. As I recall mine tends to sit just below the mid point. If it does not settle out at a normal value then the sender may be out of spec; but, it is also possible that the gauge may be out of spec. Unfortunately, without test values for sensor resistance which would allow you to confirm that the gauge is working OK you can't know for sure. Absent more information, the balance of probabilities suggests it is probably the sender that is out of spec.

According to the SM, the resistance of the sender goes

If after start up your oil pressure reading returns to a more normal value something else might be up. As I recall mine tends to sit just below the mid point. If it does not settle out at a normal value then the sender may be out of spec; but, it is also possible that the gauge may be out of spec. Unfortunately, without test values for sensor resistance which would allow you to confirm that the gauge is working OK you can't know for sure. Absent more information, the balance of probabilities suggests it is probably the sender that is out of spec.

Last edited:

During development of the cluster tester (thanks @Old Guy) I've measured the following values for the oil pressure gauge:

The current (second generation) cluster tester controls the gauge by means of PWM so there are no dedicated resistance values anymore and the calibration is done using a look-up-table in software.

During servicing of clusters I've observed a little bit of difference between individual units so the oil pressure gauge isn't a very exact instrument, to be honest.

- 0 - 76 Ω to GND

- 4 - 33 Ω to GND

- 8 - 13 Ω to GND

The current (second generation) cluster tester controls the gauge by means of PWM so there are no dedicated resistance values anymore and the calibration is done using a look-up-table in software.

During servicing of clusters I've observed a little bit of difference between individual units so the oil pressure gauge isn't a very exact instrument, to be honest.

There are no capacitors or any electronic components in the cluster associated with the operation of the oil pressure gauge. It is a pretty basic electro mechanical gauge.

Unplug the connector to the oil pressure sensor unit and then switch on the ignition. If the gauge still moves to max value then you likely have a short circuit on the wire between the cluster and the sender or in the cluster or the actual gauge is faulty. If the gauge reads zero with the sensor disconnected then there is an issue with your new sender. Did you measure the resistance of the sender as you said you were going to do? @drew reported a sensor range of 20 - 137 ohms, 137 ohms being the reading at 0 psi.

www.nsxprime.com

www.nsxprime.com

Compare the resistance of your new sender to your original sender. If they are the same then that points a finger at the gauge or the associated wiring. When you say the gauge is pegged at max, is it pegged 100% of the time even when the ignition is off, or does it sit at zero and then move to max pressure after the ignition is on? If it is pegged at max 100% of the time then the gauge may also be damaged. The service manual test for the gauge notes not to put a sustained short on the gauge sensor wire during the test as this may damage the gauge. If you have a short on the sensor wire the gauge may be damaged so you might have two problems, a short on the wiring / cluster and a damaged gauge.

First step is to confirm that the problem is not the sender by disconnecting it and checking the operation of the gauge.

Unplug the connector to the oil pressure sensor unit and then switch on the ignition. If the gauge still moves to max value then you likely have a short circuit on the wire between the cluster and the sender or in the cluster or the actual gauge is faulty. If the gauge reads zero with the sensor disconnected then there is an issue with your new sender. Did you measure the resistance of the sender as you said you were going to do? @drew reported a sensor range of 20 - 137 ohms, 137 ohms being the reading at 0 psi.

Oil Pressure Sending Unit not available

Reading the posts about low oil pressure indications and the service bulletin here : http://www.nsxprime.com/tsb-91-008/ Seems the part number 37245-PR7-002 is no longer available. Anyone know of another unit that would properly drive the gauge. Splicing wires into a connector shouldn't be...

Compare the resistance of your new sender to your original sender. If they are the same then that points a finger at the gauge or the associated wiring. When you say the gauge is pegged at max, is it pegged 100% of the time even when the ignition is off, or does it sit at zero and then move to max pressure after the ignition is on? If it is pegged at max 100% of the time then the gauge may also be damaged. The service manual test for the gauge notes not to put a sustained short on the gauge sensor wire during the test as this may damage the gauge. If you have a short on the sensor wire the gauge may be damaged so you might have two problems, a short on the wiring / cluster and a damaged gauge.

First step is to confirm that the problem is not the sender by disconnecting it and checking the operation of the gauge.

OK, diag time.

The oil guage is at zero with engine off. The oil guage goes to 8+ with engine on. With the sender disconnected, the guage is at zero with engine on. The sender is measuring 26-29 ohms at cold idle and the guage goes to 8+.

I guess the only thing left is to measure the actual oil pressure.

The oil guage is at zero with engine off. The oil guage goes to 8+ with engine on. With the sender disconnected, the guage is at zero with engine on. The sender is measuring 26-29 ohms at cold idle and the guage goes to 8+.

I guess the only thing left is to measure the actual oil pressure.

What does the sender resistance measure when it is disconnected and the engine is off? Based upon @drew 's post, you should be measuring 137 ohms (high resistance at low / no pressure and low resistance at high pressure). If the sensor measures 137 ohms when disconnected and is measuring 26-29 ohms with the engine running it would seem that you do have an oil pressure issue and measuring the pressure at the port on the oil filter would be in order.

Interesting. Seems like a pressure test with a mechanical gauge would be the next step.

Wrapping up my fix on this. I was able to fix my oil gauge reading. My oil gauge on the cluster pegged at max after engine start. It hits the stop at max. This is a different issue than what most people experience which is the gauge reading zero (this seems to be related to bad oil pressure sending unit). I replaced the oil pressure sending unit and the gauge was still pegged at max.

As I addressed other issues with my 95 MT5 NSX eventually this was the only issue that bothered me. So I ordered new gauges from Japan which comes as a unit that includes the temperature gauge. When I got the unit I realized I had order the wrong part since the graphics was slightly different, that would bother me to no end if I installed it. So I decided to remove the graphics from my old unit to put on the new unit. This required removing the needles from the gauges (I used the two spoons method - see Youtube) and peeling the graphics off each (held by strips of double sided tape). The graphics are self aligned so easy to install. The real trick is how to align the needles to show the right readings. This involved trial and error by installing the needle, bring car to operating temperature and RPM, see where the needles are, make a mark on the spline of the gauge motor, remove the needles and put them back on, try again. After about 7 tries, I was able to get the needles to show the correct operating marks.

Looking back, I think my original gauges were fine. At some point, one of the previous owners must have removed the needle for some reason (replace with yellow Type R needles?) and didn't put it back at the right place. If you were replacing the gauges for some reason, I would recommend checking to make sure you get the right part and not mess with the needles, particularly with the RPM and Speed needles, where good enough is not an option.

As I addressed other issues with my 95 MT5 NSX eventually this was the only issue that bothered me. So I ordered new gauges from Japan which comes as a unit that includes the temperature gauge. When I got the unit I realized I had order the wrong part since the graphics was slightly different, that would bother me to no end if I installed it. So I decided to remove the graphics from my old unit to put on the new unit. This required removing the needles from the gauges (I used the two spoons method - see Youtube) and peeling the graphics off each (held by strips of double sided tape). The graphics are self aligned so easy to install. The real trick is how to align the needles to show the right readings. This involved trial and error by installing the needle, bring car to operating temperature and RPM, see where the needles are, make a mark on the spline of the gauge motor, remove the needles and put them back on, try again. After about 7 tries, I was able to get the needles to show the correct operating marks.

Looking back, I think my original gauges were fine. At some point, one of the previous owners must have removed the needle for some reason (replace with yellow Type R needles?) and didn't put it back at the right place. If you were replacing the gauges for some reason, I would recommend checking to make sure you get the right part and not mess with the needles, particularly with the RPM and Speed needles, where good enough is not an option.

Similar threads

- Replies

- 5

- Views

- 365