1) We are stoked to announce a GB of 20 of our new product. A structural 100% prepreg carbon Rear Strut Bar for 91-94 coupe model. Our trusty supplier had a batch of special epoxy pregreg carbon cloth from the aerospace slowdown and we were able to procure it at an attractive price to pass on the savings to you. Normally, it is not cost effective compare to the normal 3k cloth. Please see the link below to our website for a short video of this product.

We did not build this bar to make the OEM lighter/stronger. We built it to see how the material behaves and we will incorporate honeycomb and ROHACELL in our future product since these are typically materials used in aerospace , not commonly used in automobiles due to cost but the properties are just outstanding and would be a shame not to use on an iconic car like ours.

We see this material has great potential to make cool future product not just 5-10% better but 5-10x better with zero undesirable side effect. It will not only be ~50% lighter than a metal part but also improve the MOI, CG, weight distribution, better fuel consumption, which improves the driving dynamics of our car all the time. Pending on your response, we may build another one for the targa folks to be fair but for now, if you have a coupe, this is the best time to upgrade your existing bar as the price may change after this group buy.

Information of the bar

100% 3K PREPREG CARBON REAR STRUT BAR. SPECIAL AEROSPACE PREPREG WITH ~5% LESS EPOXY RESIN THAN STANDARD 3K CLOTH. FLAME RETARD RATED @400F. COMES WITH 4 TITANIUM BOLTS. THIS IS A STRUCTURAL PIECE NOT A COSMETIC PART.

PREPREG BAR = 8.5 OZ.

OEM STEEL BAR = 17.2 OZ.

PREPREG W/ HONEYCOME BAR = 11.1 OZ.

PREPREG W/ ROHACELL FOAM BAR = 6.3 OZ.

OEM BOLTS = 1.95 OZ.

TITANIUM BOLTS = 0.97 OZ.

PRICING = $550 WITH GR. 5 TI BOLTS + SHIPPING, QTY = 20.

PRODUCTION WILL BE 4-6 WEEKS, JUST IN TIME FOR X'MAS!!

https://pole2flagracing.com/prepreg-rear-strut-bar-91-94.html

PREPREG BAR = 8.5 OZ.

OEM STEEL BAR = 17.2 OZ.

PREPREG W/ HONEYCOME BAR = 11.1 OZ.

PREPREG W/ ROHACELL FOAM BAR = 6.3 OZ.

OEM BOLTS = 1.95 OZ.

TITANIUM BOLTS = 0.97 OZ.

PRICING = $550 WITH GR. 5 TI BOLTS + SHIPPING, QTY = 20.

PRODUCTION WILL BE 4-6 WEEKS, JUST IN TIME FOR X'MAS!!

https://pole2flagracing.com/prepreg-rear-strut-bar-91-94.html

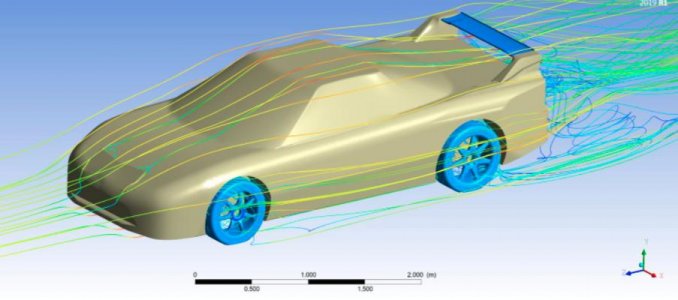

2) We are also making progress on our next project of active-aero-on-demand which is focused on exciting user-experience and more than 50%(the design work is done) complete with more pictures to follow(see link below) and IFF you buy the strut bar, we will give you a discount for the active aero set up when it's ready for market.

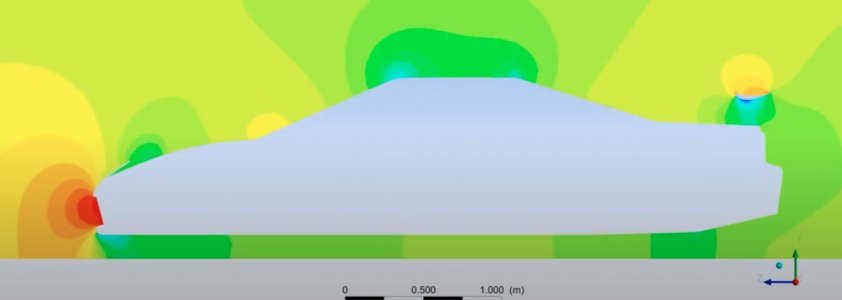

We have finished most of the modeling/designing/packaging and with no less than 100+ CFD analysis complete to provide active-aero v1.0 with targeted 320-360 lbs of total DF on-demand with a 40/60 weight distribution of a 3,000 lb. car, yet we have plenty of head room for the frt flap and rear wing angles to reach stall.

Active-aero v2.0 will have a much higher DF on-demand with a bigger, taller wing with more camber and a deeper chord than v1.0. We are making a front bumper cover from carbon/kevlar/honeycomb(~50% lighter than the OEM urethane) with an active flap attached to actuators that are mounted on the carbon bumper beam that we already make, the control buttons/knobs will be mounted on our Type R style carbon center console, the v1.0 rear wing will be located on the existing trunk and be mounted slightly higher than the Type R wing to generate the targeted DF number but with an Eppler 420 profile with a lofted center section. For once, we don't need to worry about the drag, that is nice.

Initially, we spec-ed out the active aero system using Pi Research/Cosworth of ICD, IPS, ECU, sensors...components so everything is digitally controlled via CAN bus....but the component cost quickly escalated to $30k+ before ANY design/carbon parts are made. We got scared. The system we are building is more analog and focus on user experience so YOU get to determine when to turn on/off the aero to feel the difference which is a lot of fun IMO but you need to know what you are doing thus the low DF of in the v1.0 ~350lbs range => ~10% of the weight of your car to "keep you out of deep trouble." AND, this work well between 0-100-0 mph where most of us spending our time.

Yes, in short, we need your support to bring the active aero project to fruition. It is something we want to do before we kick the bucket. BTW, this set up is designed specifically for the Gen 1 NSX 1991-2005 with the OEM body shape in mind and all parts are reverse-able back to oem if necessary. If you purchase the strut bar, we will give you a discount for the active-aero setup should you decide to have one. This product is gonna be a lot of fun to use....all the time.

Active Aero R&D

Thx to Hoonigan for this review, this was the car we were involved in design and building working with Trevor Harris(trevorlharris.com), Don Devendorf(+/-), Wes Moss(mechanicals), Yoshi(Aero), John Caldwell(Engine R&D), Andy Galloway(composite), Bill Dailey(Dailey Dry Sump), Rob Edwards(Alex Rossi Strategist), Chris Willis(Real Time NSX GT3), and many other very gifted folks. After finishing engine R&D of the 4-valve 3.0, we moved on to suspension design and aero support. It was a privilege and extremely valuable experience working with them learning how to think and how to apply theory to real life cases, learning what not to do besides drawing circles and lines all day on CAD. Ignore the hideous intake periscope...but it was worth xtra 50hp needed to chase the AAR Toyota but Geoff Brabham had a fit. "WTH is this?" Chip Robinson was "ok" with it. Pay attention to what Trevor has to say, he has a physics background and we always learn something just listening to him. Kinda like an "American" Gordon Murray to us.

10,000lbs of Downforce at 200mph: Nissan’s Wild 950hp IMSA GTP Cars

Attachments

Last edited: