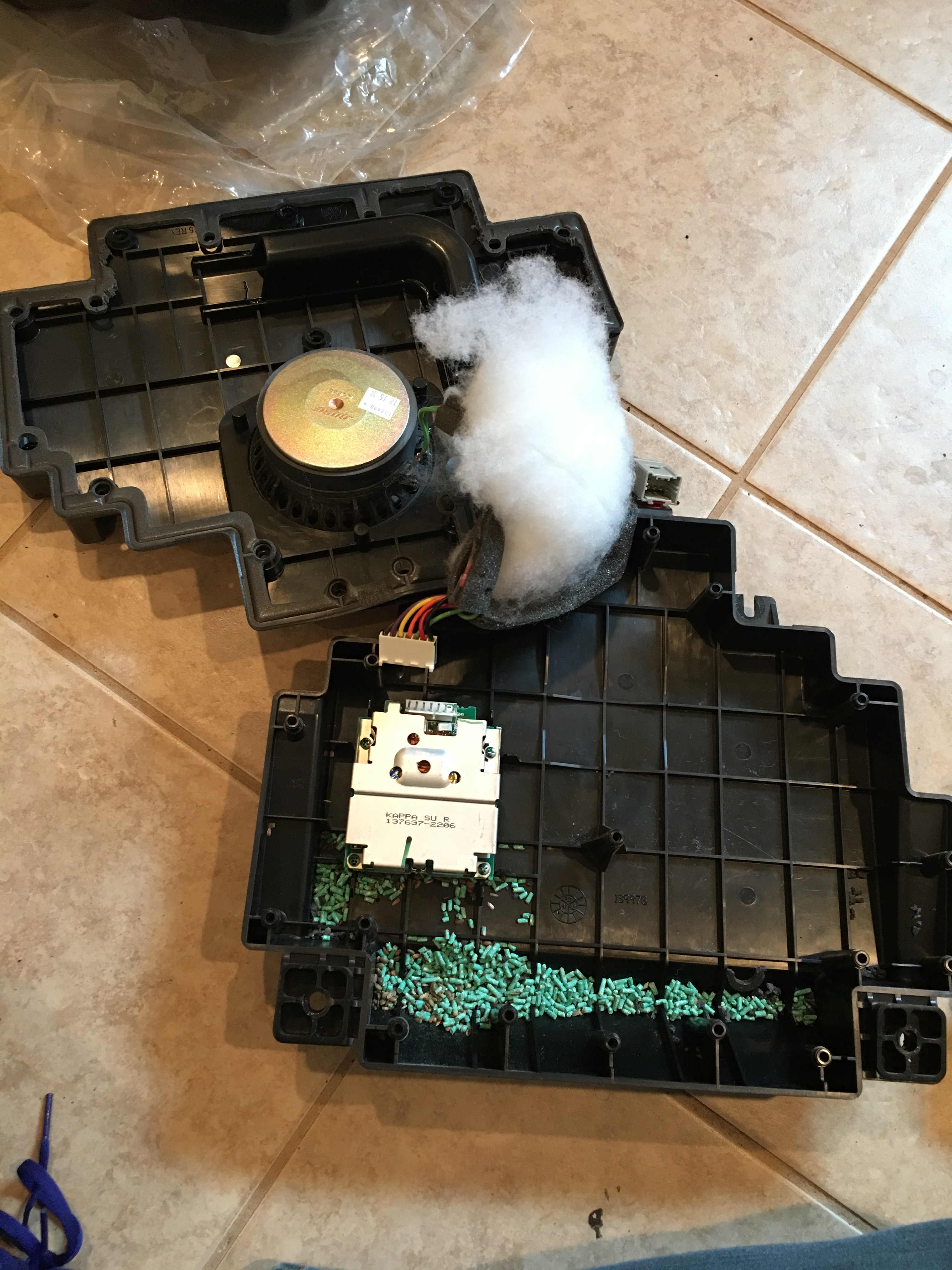

I'm in the process of rebuilding my OEM Bose amplifiers, would there be any interest in a DIY how-to video and parts list? If you have some basic soldering skills it's pretty straightforward and the parts themselves are less than $30 to do all 3 amplifiers, which is far cheaper than either replacing the whole speaker boxes or paying someone to rebuild them for you. The stock Bose system is actually decent when the amps work right.

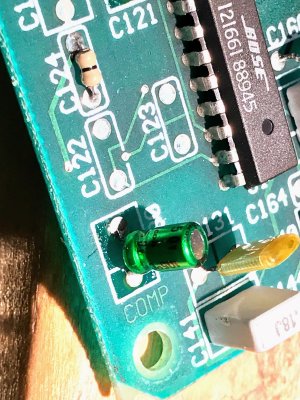

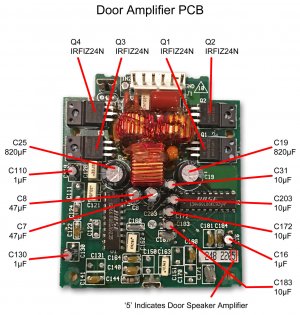

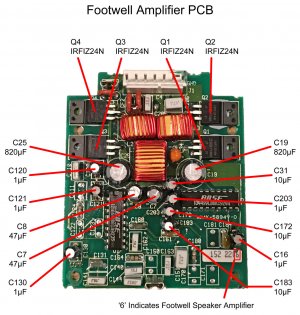

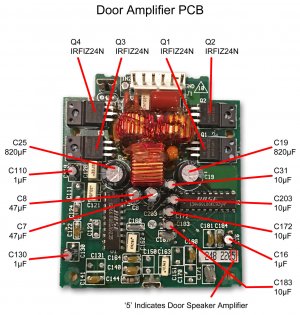

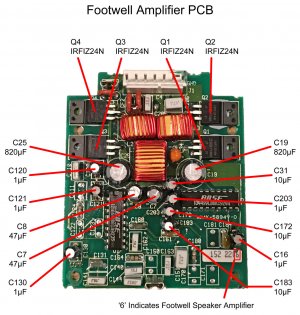

There are a few different revisions of the amplifier boards and the capacitors are slightly different between those versions, so right now, the parts list is only accurate if your board looks like the photos below. If anyone has the different style amplifier boards please let me know so I can get the info together for them as well.

Tools Needed

If you don't have access to most of this stuff already this project probably isn't for you, while not difficult, this is not a good "babbys first soldering project". If you don't already have a soldering iron and know how to use it, turn back.

- Multimeter for checking your work.

- Soldering iron. (25W or less)

- Rosin flux.

- Lead solder. (you can use lead free but it's much more difficult to work with)

- Desoldering braid or solder sucker, whichever works better for you.

- Fine needle nose pliers or tweezers.

- Tiny wire clippers or scissors.

- Flux remover.

- Conformal coating.

Parts List

Current as of 11/2017, parts will likely be unavailable in a few years and new ones will need to be selected.

Capacitor, 1uF, 50V

Door Board P/N: C16, C110, C130

Footwell Board P/N: C16, C120, C121, C130, C203

Suitable replacement: Rubycon 50YXJ1M5X11

https://www.digikey.com/product-detail/en/rubycon/50YXJ1M5X11/1189-1421-ND/3134377

Capacitor, 10uF, 35V

Door Board P/N: C31, C172, C183, C203

Footwell Board P/N: C31, C172, C183

Suitable replacement: Rubycon 50YXJ10M5X11

https://www.digikey.com/product-detail/en/rubycon/50YXJ10M5X11/1189-2322-ND/3562914

Capacitor, 47uF, 16V (same for door and footwell amps)

Board P/N: C7, C8

Suitable replacement: Rubycon 50YXJ47M6.3X11

https://www.digikey.com/product-detail/en/rubycon/50YXJ47M6.3X11/1189-2325-ND/3563118

Capacitor, 820uF, 16V (same for door and footwell amps)

Board P/N: C19, C25

Suitable replacement: Rubycon 16ZLQ820MEFC10X12.5

https://www.digikey.com/product-detail/en/rubycon/16ZLQ820MEFC10X12.5/1189-3630-ND/6049867

MOSFET (same for door and footwell amps)

Board P/N: Q1, Q2, Q3, Q4

Suitable replacement: IRFIZ24NPBF

https://www.digikey.com/product-detail/en/infineon-technologies/IRFIZ24NPBF/IRFIZ24NPBF-ND/811806

If you do all 3 (and you might as well do all 3 since parts are so cheap), I'd order 15x1uF, 15x10uF, 10x47uF, 10x820uF, and 15 MOSFETs. You want a few extras of each in case you ruin one or you get a bad part, the total should be under $30 shipped from Digikey, Mouser, etc. Also, the MOSFETs don't need to be replaced unless they have failed, but I went ahead and replaced mine anyways and added thermal transfer paste to help keep them a bit cooler.

Parts To Be Replaced

(Thanks to user BrianK for helping me figure out which capacitors go where on this board after I mixed them up by mistake.)

Video Tutorial

Raw footage has been recorded and I'm in the process of editing it.

Also many thanks to users Kaz-kzukNA1, BrianK, and Old Guy for contributing to information in this post.

There are a few different revisions of the amplifier boards and the capacitors are slightly different between those versions, so right now, the parts list is only accurate if your board looks like the photos below. If anyone has the different style amplifier boards please let me know so I can get the info together for them as well.

Tools Needed

If you don't have access to most of this stuff already this project probably isn't for you, while not difficult, this is not a good "babbys first soldering project". If you don't already have a soldering iron and know how to use it, turn back.

- Multimeter for checking your work.

- Soldering iron. (25W or less)

- Rosin flux.

- Lead solder. (you can use lead free but it's much more difficult to work with)

- Desoldering braid or solder sucker, whichever works better for you.

- Fine needle nose pliers or tweezers.

- Tiny wire clippers or scissors.

- Flux remover.

- Conformal coating.

Parts List

Current as of 11/2017, parts will likely be unavailable in a few years and new ones will need to be selected.

Capacitor, 1uF, 50V

Door Board P/N: C16, C110, C130

Footwell Board P/N: C16, C120, C121, C130, C203

Suitable replacement: Rubycon 50YXJ1M5X11

https://www.digikey.com/product-detail/en/rubycon/50YXJ1M5X11/1189-1421-ND/3134377

Capacitor, 10uF, 35V

Door Board P/N: C31, C172, C183, C203

Footwell Board P/N: C31, C172, C183

Suitable replacement: Rubycon 50YXJ10M5X11

https://www.digikey.com/product-detail/en/rubycon/50YXJ10M5X11/1189-2322-ND/3562914

Capacitor, 47uF, 16V (same for door and footwell amps)

Board P/N: C7, C8

Suitable replacement: Rubycon 50YXJ47M6.3X11

https://www.digikey.com/product-detail/en/rubycon/50YXJ47M6.3X11/1189-2325-ND/3563118

Capacitor, 820uF, 16V (same for door and footwell amps)

Board P/N: C19, C25

Suitable replacement: Rubycon 16ZLQ820MEFC10X12.5

https://www.digikey.com/product-detail/en/rubycon/16ZLQ820MEFC10X12.5/1189-3630-ND/6049867

MOSFET (same for door and footwell amps)

Board P/N: Q1, Q2, Q3, Q4

Suitable replacement: IRFIZ24NPBF

https://www.digikey.com/product-detail/en/infineon-technologies/IRFIZ24NPBF/IRFIZ24NPBF-ND/811806

If you do all 3 (and you might as well do all 3 since parts are so cheap), I'd order 15x1uF, 15x10uF, 10x47uF, 10x820uF, and 15 MOSFETs. You want a few extras of each in case you ruin one or you get a bad part, the total should be under $30 shipped from Digikey, Mouser, etc. Also, the MOSFETs don't need to be replaced unless they have failed, but I went ahead and replaced mine anyways and added thermal transfer paste to help keep them a bit cooler.

Parts To Be Replaced

(Thanks to user BrianK for helping me figure out which capacitors go where on this board after I mixed them up by mistake.)

Video Tutorial

Raw footage has been recorded and I'm in the process of editing it.

Also many thanks to users Kaz-kzukNA1, BrianK, and Old Guy for contributing to information in this post.

Last edited: