Good morning NSXPrime!

I was noticing a "clunk" when pulling into my garage or parking spaces, which I found was due to a torn front engine mount. I decided that it was time to replace all of them while I'm at it. In doing some research, I found 4 options at the moment:

So I pulled the trigger and purchased the Foundry3 mounts. Chris was quick to provide the mounts and responsive during the purchase process. The mounts arrived exactly as advertised. Here is a side by side of the rear mount:

During my research, I found very few pictures or notes about engine mount replacement on NSXPrime, so I took a few pictures during the job and I've included a few notes to help out future owners replacing their mounts.

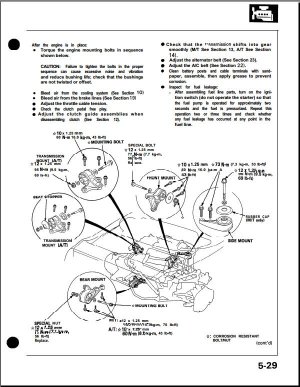

Lift the rear of the car and set on a pair of jack stands. Have a floor jack (with a 2x4) supporting the engine when changing the mounts.

Passenger Side Mount - You will need to remove the alternator first. Once removed, it is easy to swap the mount.

Driver Side Mount - Remove the air filter housing and a couple small hoisting brackets on the transmission.

Rear Mount - This is by far the easiest mount. If you are replacing only this mount, you can remove the 4 bolts on the rear of the brace below the mount and actually use a prybar to get the 1/2" of play needed to get one of the bolts out. If you are replacing the front mount as well, then you will need to remove the whole brace anyways, so just replace the rear after you have removed the brace. (I didn't do it in this order, and looking back it would have saved me an hour or so of work.)

Front Mount - This is the most difficult mount. You will need to remove the shifter linkage to the transmission, the brace under the engine, and the cross-member. I recommend making sure you have a wobbly socket to access the engine mount bolt to loosen it. I couldn't imagine doing the job without that. Once the cross-member is removed, the mount is easily accessible for replacement.

Now came the tricky part for me. I installed the new mount and after re-installing the cross-member, found that the mount did not quite line up with the hole anymore:

The above pictures were taken with the other 3 mounts already replaced. Ultimately, I had to go back to the rear mount and loosen it, then using a prybar on the rear mount, and the jack under the transmission, I was able to get this lined up:

I'm not sure if this would have been the same headache with OEM mounts, but I wanted to make a note of it here. Looking back, if I would have done the rear last, this job probably would have been a bit easier. Overall, the fitment of the drivers, passenger, and rear mounts was absolutely perfect. As mentioned above, the front mount did require a little work to line up, but the mounting fitment was perfect. I split this project in half, and found the drivers, passenger, and rear mount took about 2-3 hours total, and the front mount took about 4 hours.

Took the car for a drive afterwards, and immediately upon backing out of the garage I noticed an improvement. The "clunk" was gone and everything felt tighter when initially releasing the clutch from a stop.

I hope this write-up helps future owners. Feel free to PM me directly if you have any questions!

I was noticing a "clunk" when pulling into my garage or parking spaces, which I found was due to a torn front engine mount. I decided that it was time to replace all of them while I'm at it. In doing some research, I found 4 options at the moment:

- OEM - Most expensive, but usually can't go wrong with fitment or manufacturing issues

- SOS - They offer a core exchange program where they modify the original mounts with a more durable design (https://www.scienceofspeed.com/inde...ofspeed-sport-engine-transmission-mounts.html)

- Innovative - These were by far the cheapest option. However, they would require shorter bolts than factory, and the mounts are steel. Mixing steel and aluminum had me concerned about the possibility of corrosion in the future.

- Foundry3 - The set of all 4 is less expensive than OEM or SOS, the material is billet aluminum, and bushings that won't tear like OEM (https://www.foundry3studios.com/product/91-05-nsx-billet-motor-mounts). I must also add that these look absolutely beautiful!

So I pulled the trigger and purchased the Foundry3 mounts. Chris was quick to provide the mounts and responsive during the purchase process. The mounts arrived exactly as advertised. Here is a side by side of the rear mount:

During my research, I found very few pictures or notes about engine mount replacement on NSXPrime, so I took a few pictures during the job and I've included a few notes to help out future owners replacing their mounts.

Lift the rear of the car and set on a pair of jack stands. Have a floor jack (with a 2x4) supporting the engine when changing the mounts.

Passenger Side Mount - You will need to remove the alternator first. Once removed, it is easy to swap the mount.

Driver Side Mount - Remove the air filter housing and a couple small hoisting brackets on the transmission.

Rear Mount - This is by far the easiest mount. If you are replacing only this mount, you can remove the 4 bolts on the rear of the brace below the mount and actually use a prybar to get the 1/2" of play needed to get one of the bolts out. If you are replacing the front mount as well, then you will need to remove the whole brace anyways, so just replace the rear after you have removed the brace. (I didn't do it in this order, and looking back it would have saved me an hour or so of work.)

Front Mount - This is the most difficult mount. You will need to remove the shifter linkage to the transmission, the brace under the engine, and the cross-member. I recommend making sure you have a wobbly socket to access the engine mount bolt to loosen it. I couldn't imagine doing the job without that. Once the cross-member is removed, the mount is easily accessible for replacement.

Now came the tricky part for me. I installed the new mount and after re-installing the cross-member, found that the mount did not quite line up with the hole anymore:

The above pictures were taken with the other 3 mounts already replaced. Ultimately, I had to go back to the rear mount and loosen it, then using a prybar on the rear mount, and the jack under the transmission, I was able to get this lined up:

I'm not sure if this would have been the same headache with OEM mounts, but I wanted to make a note of it here. Looking back, if I would have done the rear last, this job probably would have been a bit easier. Overall, the fitment of the drivers, passenger, and rear mounts was absolutely perfect. As mentioned above, the front mount did require a little work to line up, but the mounting fitment was perfect. I split this project in half, and found the drivers, passenger, and rear mount took about 2-3 hours total, and the front mount took about 4 hours.

Took the car for a drive afterwards, and immediately upon backing out of the garage I noticed an improvement. The "clunk" was gone and everything felt tighter when initially releasing the clutch from a stop.

I hope this write-up helps future owners. Feel free to PM me directly if you have any questions!