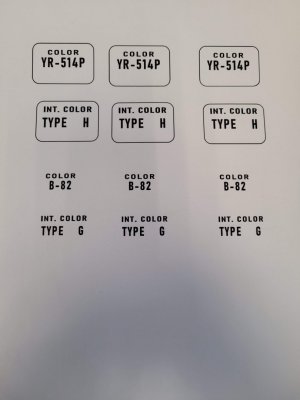

Your printed paint code stickers are a nice OCD detail.

Your comments about non linearity in the injectors surprises me. I was using a very old Bosch series injector on another car. Because the internet data on the injector was all over the place (including sources that claimed to be based upon Bosch catalog info), I actually did my own flow tests, measuring the fuel delivery for a fixed set of pulses from pulse widths starting at 0.25 msec right up to 10 msec at 0.5 msec intervals. I wanted to confirm the flow rate, determine the injector offset and offset voltage sensitivity and determine the linear region. To get an accurate assessment of where the injectors went linear I did 0.25 msec spacing for the PW between 0.25 and 1.5 msec. When you plot this data and take the slope the slope turns out to be the injector flow rate.

These injectors turned out to be 551 cc/min @ 43.5 psi. As expected, the injectors were highly non linear at very low PW values, actually flowing nothing at 0.25 msec PW. However, once above 1.0 msec the injector flow versus PW was an absolutely straight line out to 10 msec PW. I did a validity check by opening the injector for 30 seconds for a bulk flow measurement, measuring a delivery of approximately 277 cc which indicated that the injector appeared to be linear from 1 msec to 30,000 msec (approximately because I didn't have a graduated cylinder large enough for 277 cc so I had to use a measuring cup).

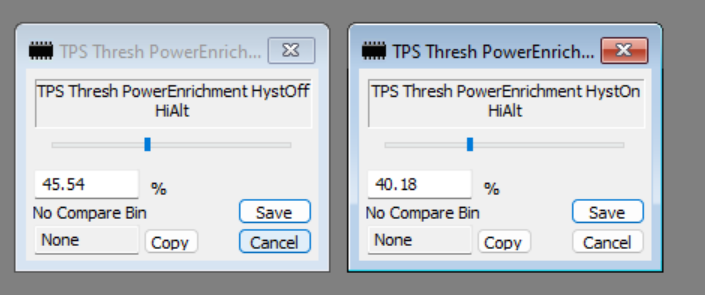

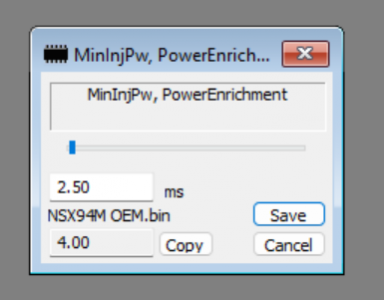

The normal practise is to size the injectors so that the idle pulse widths are just out of the low pulse width non linear region. If you have a flow versus PW curve for your injectors and you find that your idle PW are in the non linear region of operation you are kind of in terra incognito. As I recall you are using OEM injectors and I would be surprised if Honda specified injectors that were operating anywhere close to the low flow non linear region. That operating uncertainty is not good for passing emission compliance tests. The other variable is the injector offset value (where the injector slope line crosses the X axis). Some people refer to this as the opening time; but, it isn't. Errors in the injector offset value can cause the flow delivery to skew rich or skew lean depending on the sign of the error. At low pulse width values this error can be a problem because the offset may be significant compared to the injector PW. If the injector is running at high PW, errors in the offset are less significant. My offsets are around 0.21 msec at 12 volts. If you are idling with a PW of 1.5 msec, the offset is around 15% of the PW value and errors can be material to your AFR. If the PW is up around 9 msec my offset is about 2.3% and errors are less material. If you have unintentionally biased your fuel mix to correct an offset error at low PW values, depending on how you determined the bias you may have biased the AFR in the other direction at high PW values. The added complication is that injector offset is very voltage sensitive. My injector offset of + 0.21 msec at 12 volts actually slides across the axis and becomes -0.08 msec if the injectors are operating at 16 volts. Most ECUs have a compensation curve that corrects the injector offset for measured voltage to allow good idle performance.

I remember that when the Prospeed RDX injector kit came out, there were people complaining about poor idle performance. My initial reaction was that you put a larger injector on the same engine, chances are you have pushed that injector into its non linear low flow region which is going to result in unstable operation. I recall that there were some software tweaks to try and fix this and thinking to myself that they may have fiddled the offsets to try and make the injector better behaving at low PW. Since you said you had started with a Prospeed tune, you might want to check to see what is in there for injector offset values and voltage sensitivities. Unless somebody else has done this work, it might be useful to set up a small flow bench to confirm the linear region of the injectors and actually measure the injector offsets and voltage sensitivity. That would actually seem to fit right in with your OCD attention to detail

.