Plastic clips?

I am truly impressed as I am reading through your thread for the first time. I am new to the nsx community and am really inspired by all the work you have done on your car . I have tried ordering a few different plastic clips for these rear interior pieces as several of mine are missing and broken but can’t find the right part number or place to order from. Any advice is greatly appreciated.

. I have tried ordering a few different plastic clips for these rear interior pieces as several of mine are missing and broken but can’t find the right part number or place to order from. Any advice is greatly appreciated.

Thanks,

Ahmad

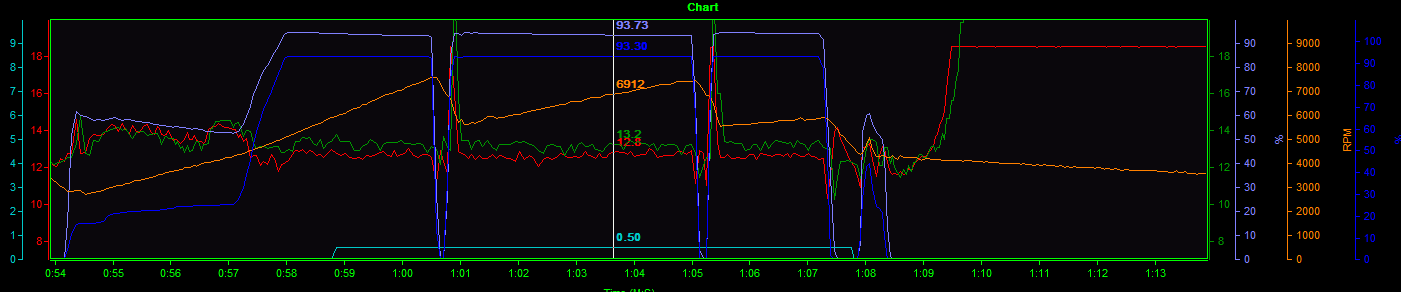

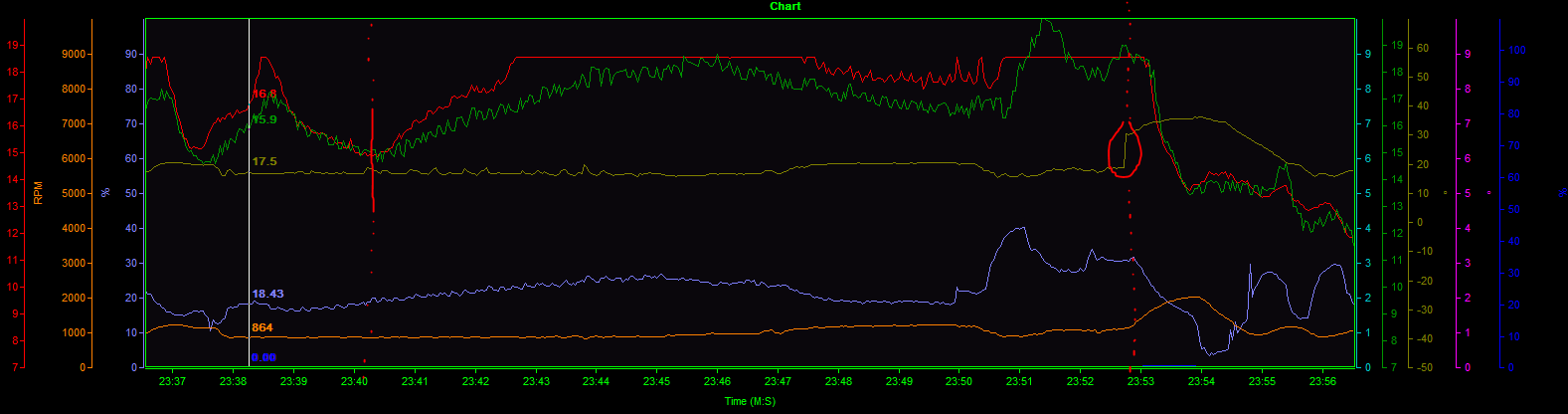

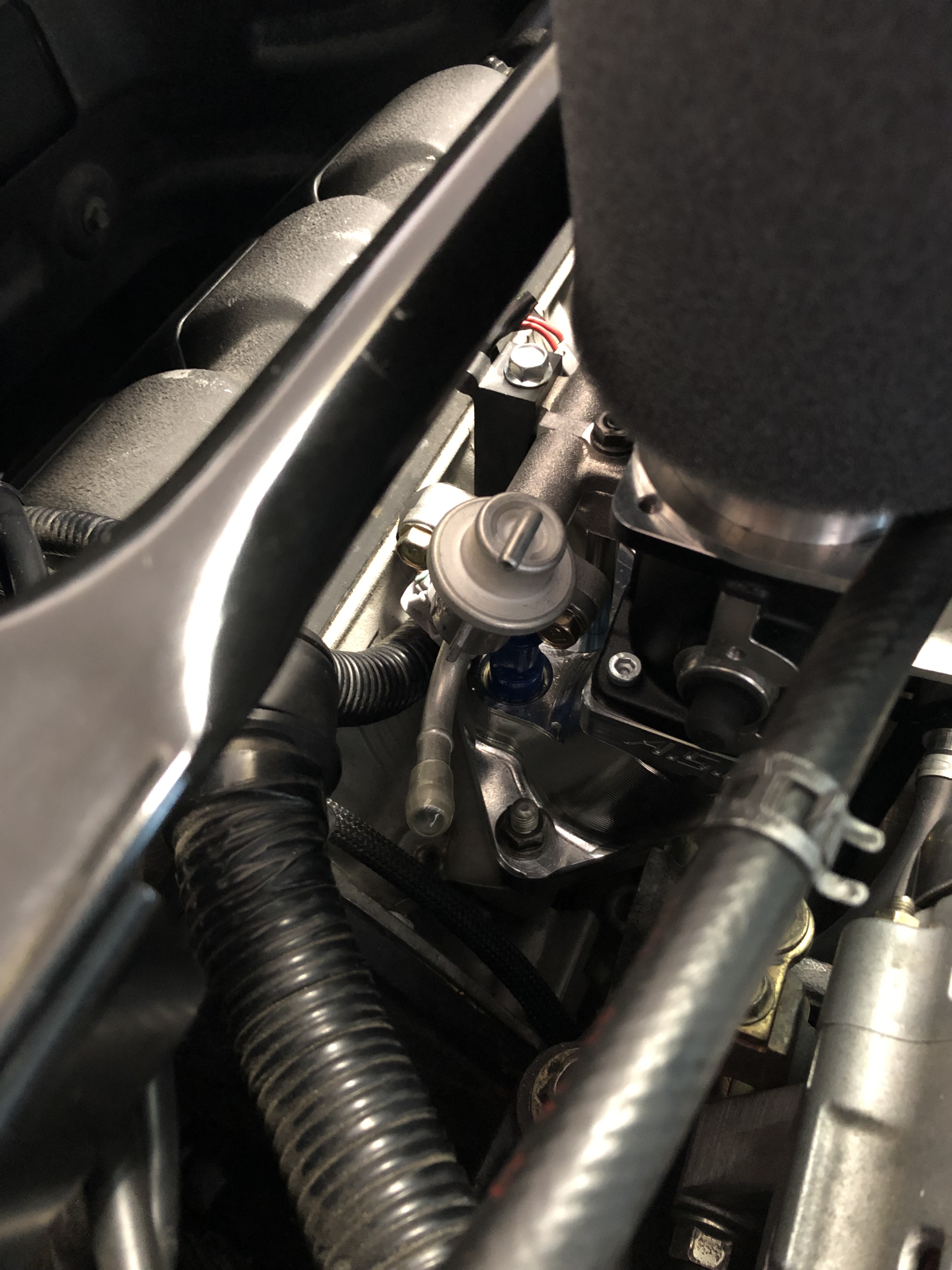

I haven't been able to get the VVIS screws out of my mind so I pulled the intake manifold to clean and check everything. Of course, the screws hadn't moved at all, so I just applied some penetrating thread locker as a precaution. From here on out I'll just be checking the screws with a borescope during oil changes.

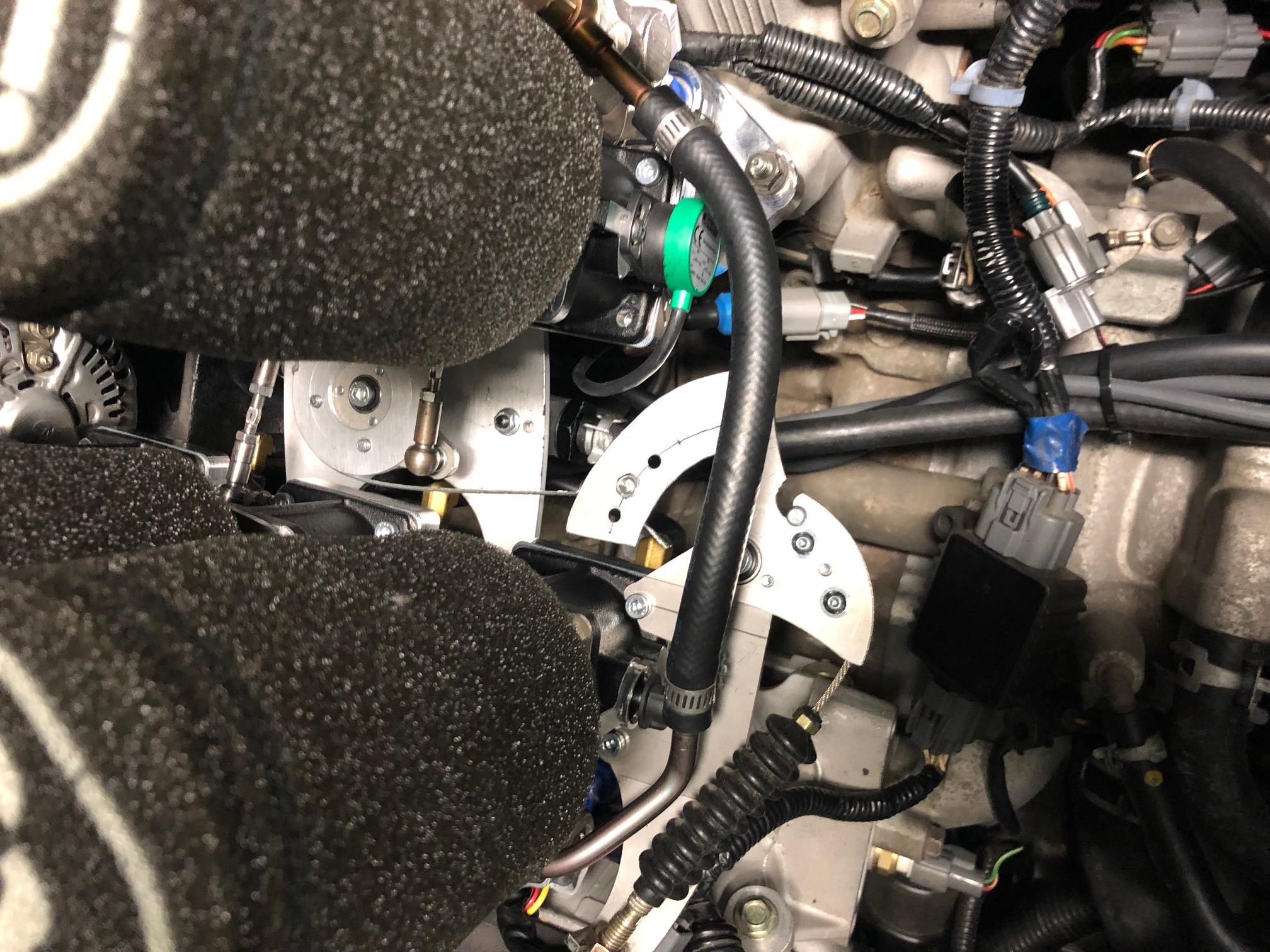

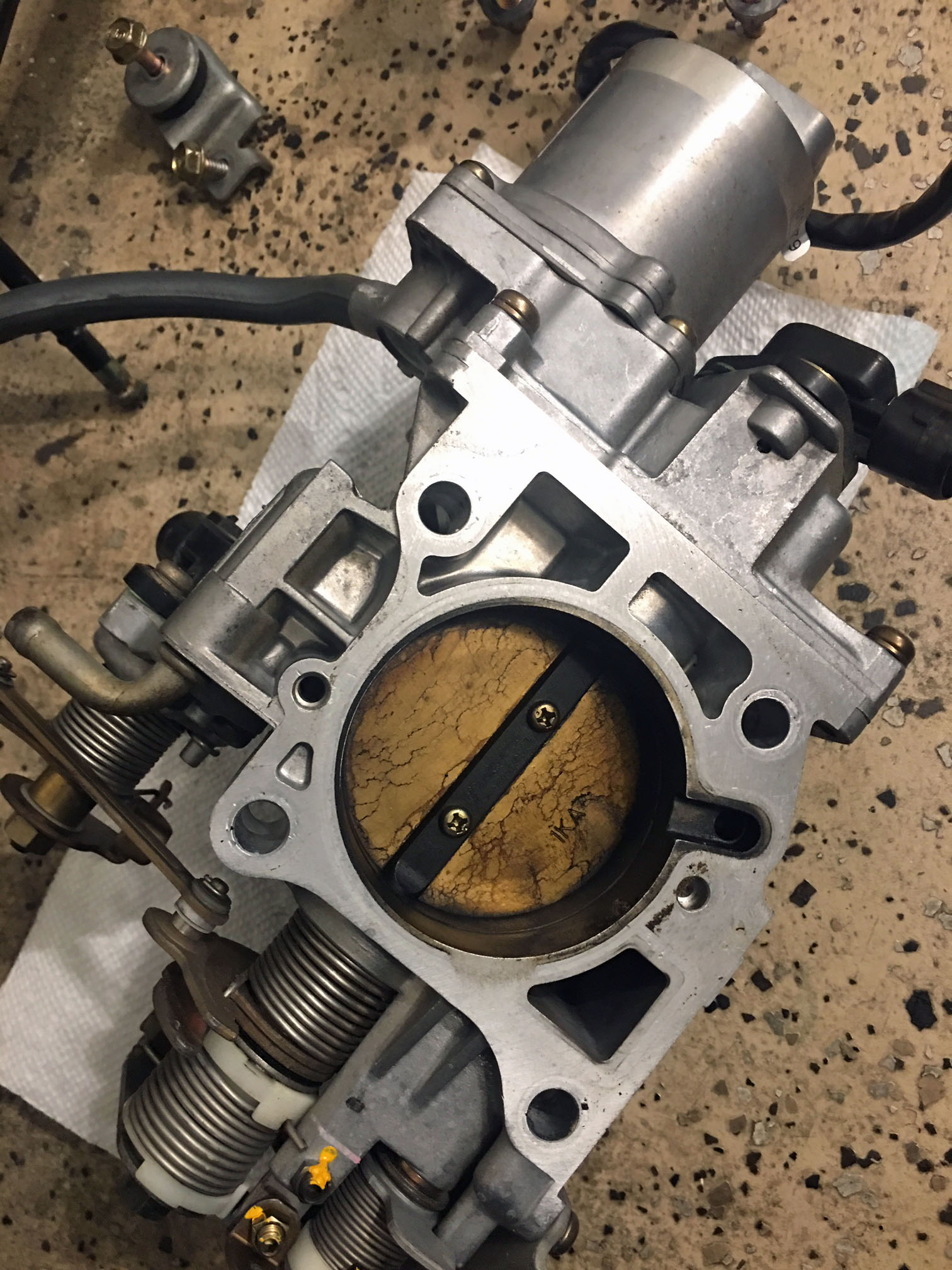

I hadn't really messed with this part of the engine before, so the sheer number of vacuum and coolant lines running to things was very surprising. I had forgotten just how many vacuum lines cars from the early 90s had, and this throttle body is just ridiculous.

Also pretty dirty, but should clean up just fine.

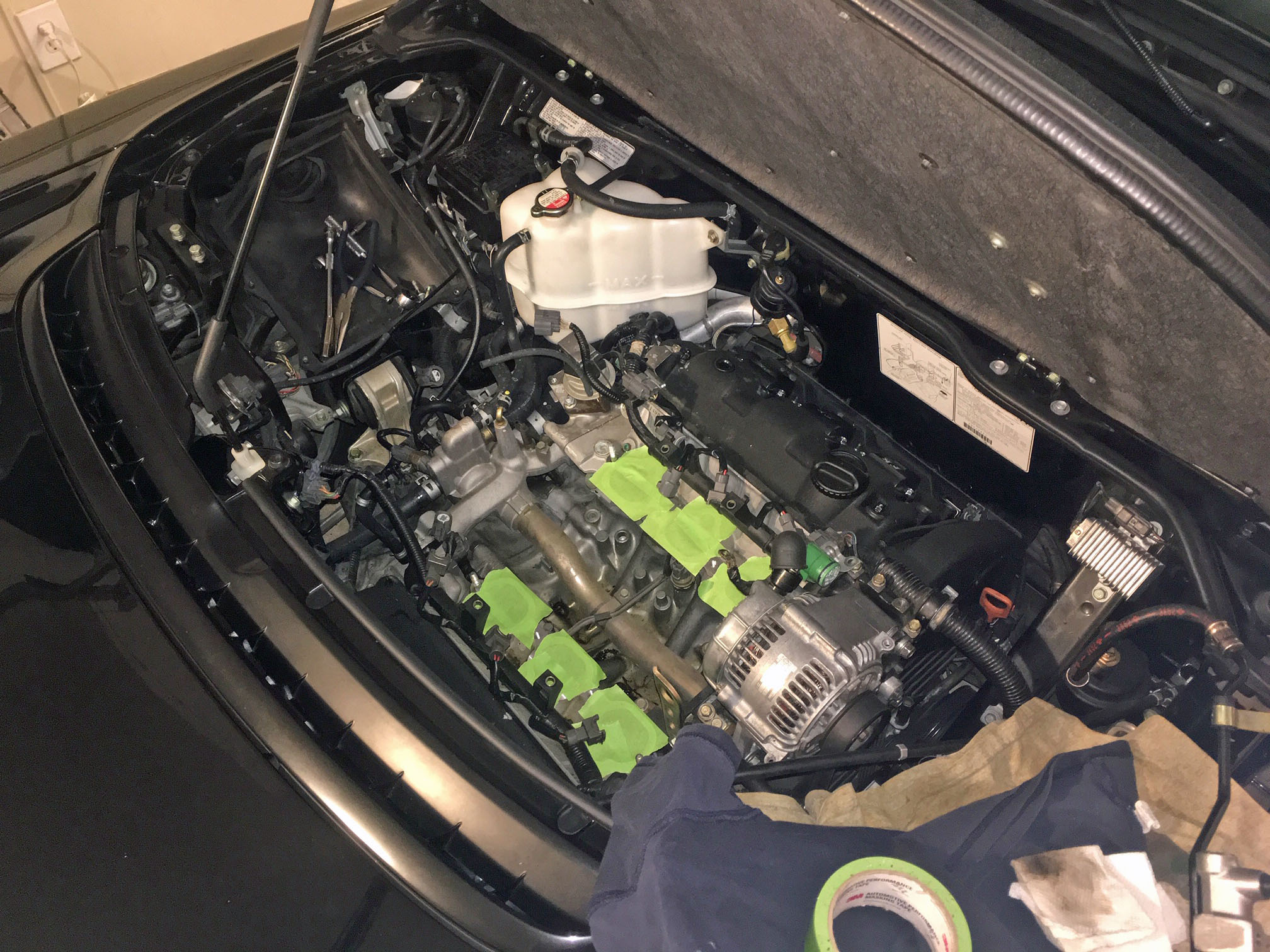

Intake manifold removed and intake ports taped up. There was a film of oil in the bottom of the V from a past VCG leak.

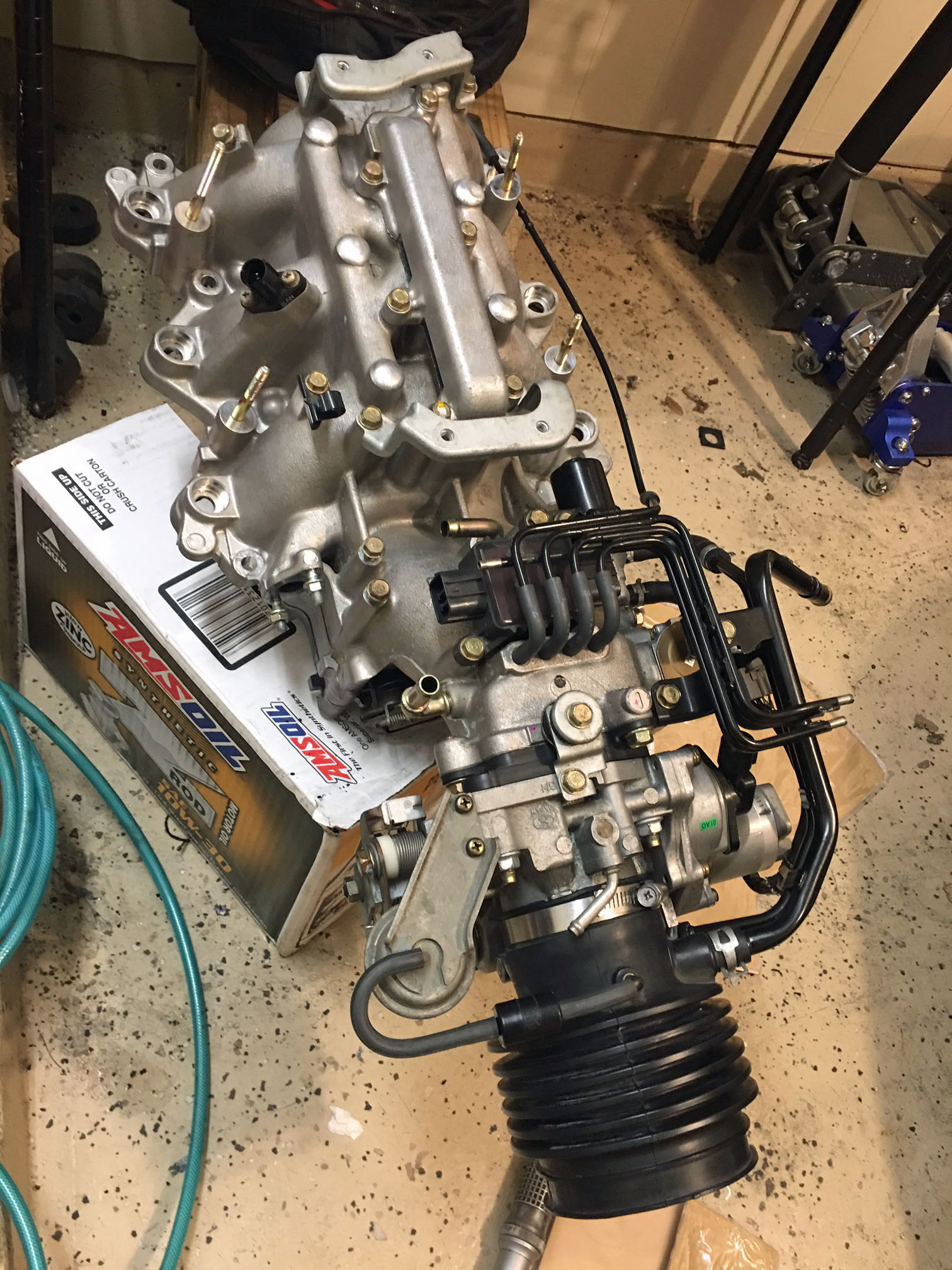

Kinda neat how the bottom part of the intake manifold is magnesium.

Intake manifold cleaned, all gaskets/O-rings replaced, and being reassembled.

Right before the manifold went back on. Tape removed, gasket surfaces cleaned, new gaskets in place.

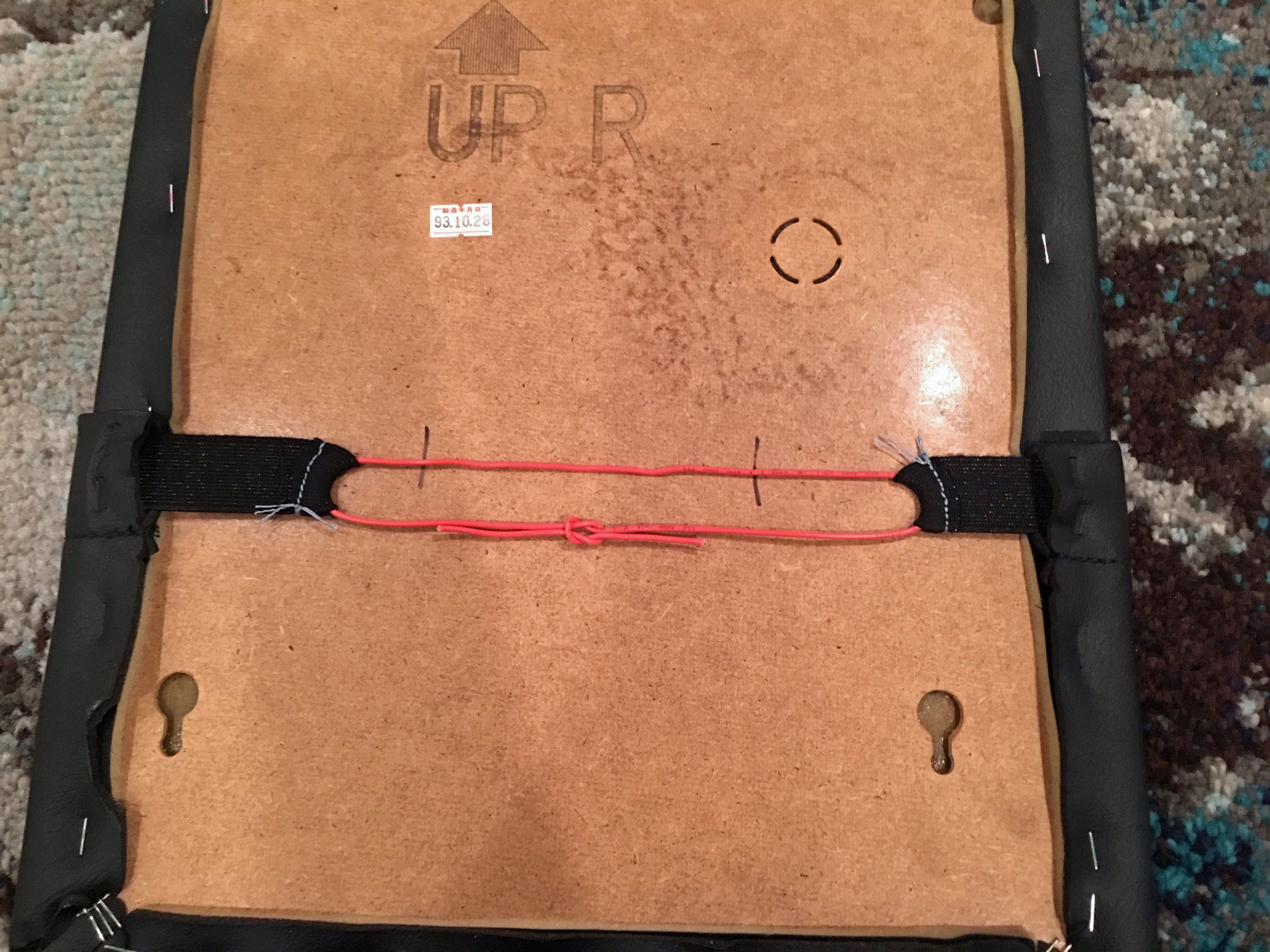

Also, while my Ridies seat covers were being installed by a local upholsterer, I decided to pull all of the panels covering the rear bulkhead and clean them up. Some of them had been removed and reinstalled before I got the car so they were a bit loose and squeaked a bit. I added some felt around the edges to help prevent squeaks and replaced all of the plastic clips. Also, one side of the elastic supporting the pocket on the passenger side had come undone as it's just stapled to the particle board backing of the panel.

I repaired the broken elastic by stitching a loop on each end and using wire to hold the ends together. This should hold much better than the staples.

Everything cleaned and ready for reinstallation.

And back in the car.

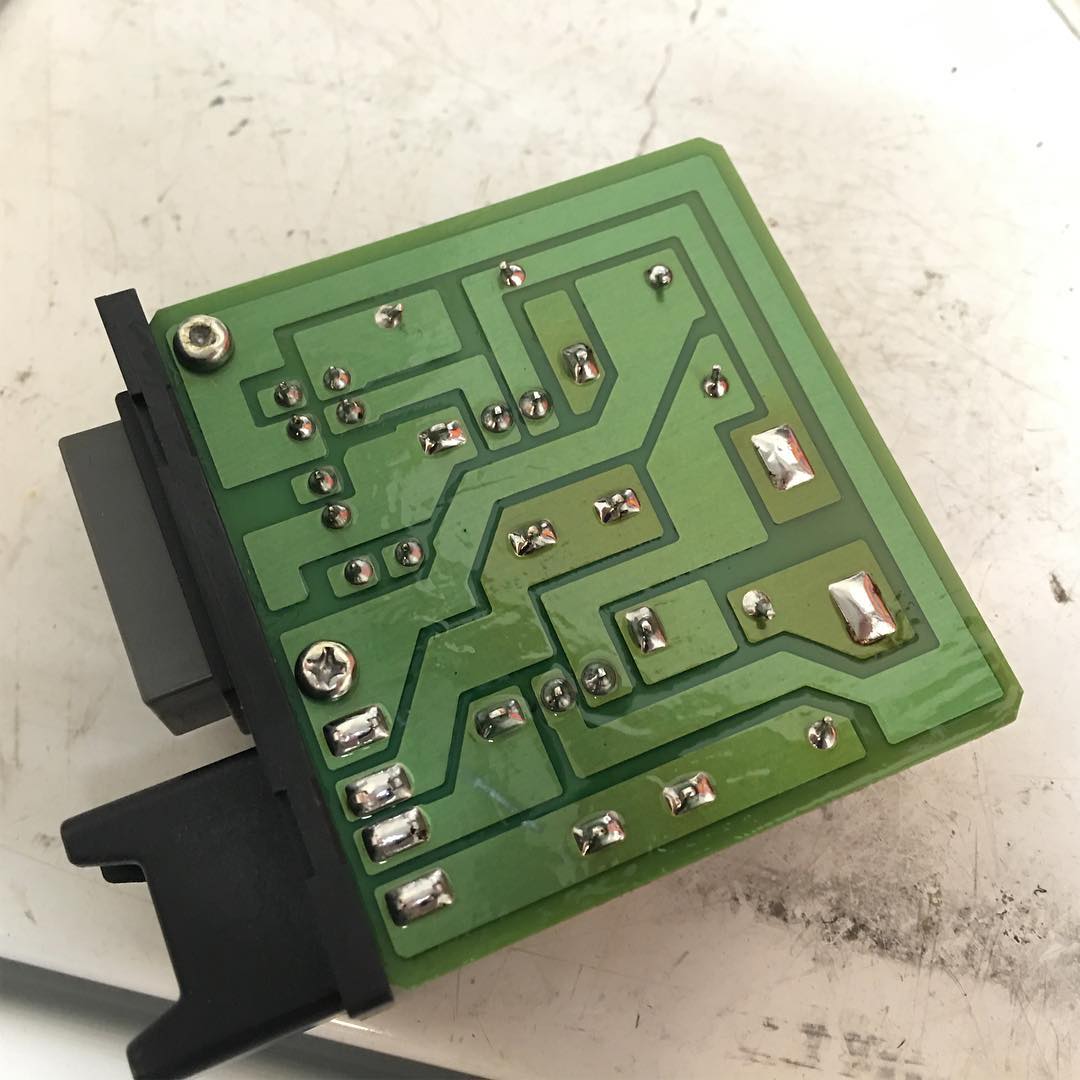

I also resoldered the main relay and applied a conformal coating since I had easy access to it with the rear panels off.

I did a leakdown test out of curiosity/precaution and I'm super happy with the results. Very consistent ~1psi drop across all cylinders with a 50psi input pressure.

Order is

3 6

2 5

1 4

My upholsterer had some things come up so I don't have my seats back, but they should be done within a week or so.

I am truly impressed as I am reading through your thread for the first time. I am new to the nsx community and am really inspired by all the work you have done on your car

Thanks,

Ahmad