My car built is in the built section

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Official ITB Reference Thread

- Thread starter integrals

- Start date

I ask for a membership in the ITB club, please!

My setup incl airbox!

Any installed pics?

I left a msg on his build thread but I don't believe he has it installed as of a couple of months ago. I'm curious why!Any installed pics?

https://www.youtube.com/watch?time_continue=7&v=QF4Nw4cy3G0

Hi

I had no time until now. But it will be on the engine soon.

I had no time until now. But it will be on the engine soon.

can't wait! can you share who made the kit? I couldn't find it on your thread.Hi

I had no time until now. But it will be on the engine soon.

can't wait! can you share who made the kit? I couldn't find it on your thread.

Nice! Looks like Jenvey SF throttles.

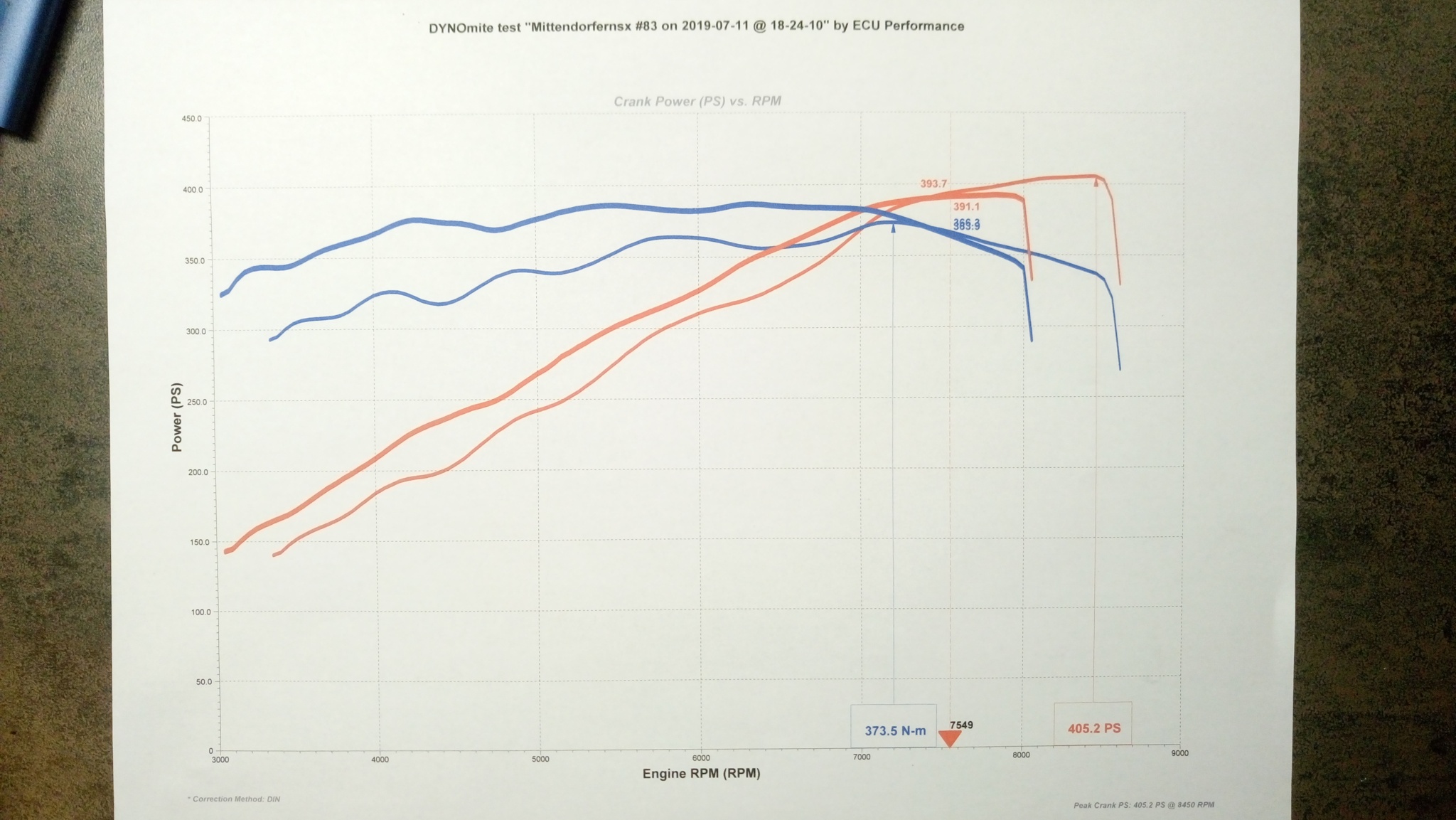

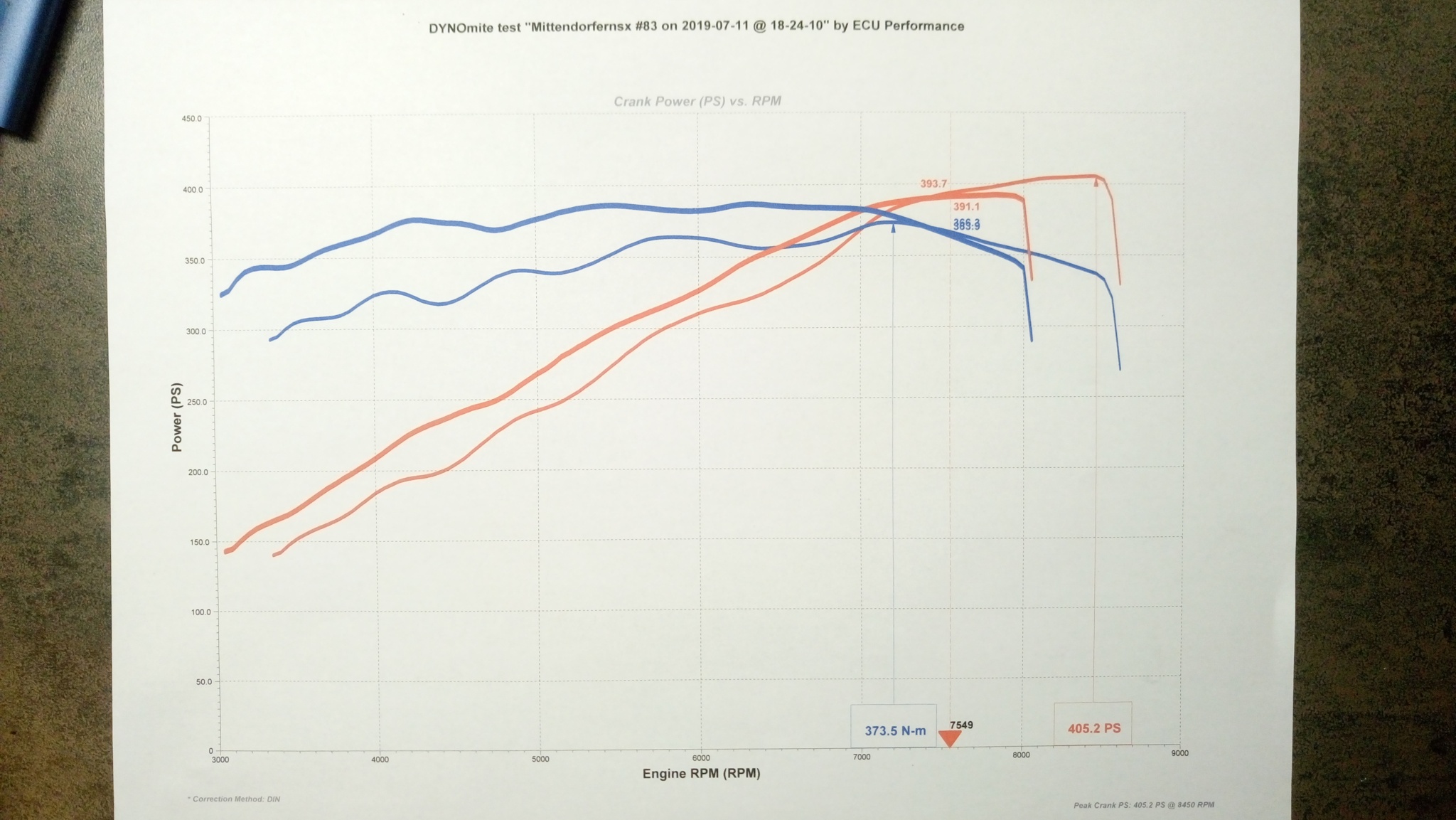

Today our newest built engine cracked the magic 400 number. It is a 3,2 ltr. with Toda C and ITBs. The dyno chart compares the old 3,5 VS the 3,2 which makes a bit less tourqe. We are looking for another 10-15hp by adding a airbox and use 1cm shorter funnels. If anybody like to knwo how many WHP those are: ~348WHP. 14% is the drive train lost.

It needs much effort to setup an ITB. I spent the whole day on the dyno. Many thanks to ECU performance in Vienna and Doctronic.at for dynoing our car with so much passion and perfection

It needs much effort to setup an ITB. I spent the whole day on the dyno. Many thanks to ECU performance in Vienna and Doctronic.at for dynoing our car with so much passion and perfection

Last edited:

Curious why 3.2 liters instead of 3.5 for the previous?

The stroker engine had rod bearing, crank and rod damage. WE are not sure, it could be to much G force for the oil get sucked by the pump. I have capacity up pan with baffles and overfill 1cm above MAX at the dip stick. I had no dataloging, so it could be a crank material failure too. I have now installed an accusump tp be safe.

I am more than happy with the intake temps of the new ITB setup. While the intake temp was measured right at the filter under the hatch and those were climbing quickly to 66C when the car stoped, the temps felt to 26C degrees after 60 Seconds of driving. This was with about 20C outsde temp.

Wow, you guys rev'd it out to 8500 rpm. I didn't see that before. I bet it was screaming.

And interesting that the hp/tq crossover is at 7250(ish) instead of the usual 5252.

phat lines are the 3,5i strocker and the slim lines are the ITB engine with 3,2. VTEC is late, at about 6800, cause before the power would suffer. We tested it of course.

What cams, piston compression ratio and fuel are you using to get 400rwhp out of a 3.2l? Awesome job

What cams, piston compression ratio and fuel are you using to get 400rwhp out of a 3.2l? Awesome job

thanks, but it is not wheel HP, its crank hp. 11.5:1, Toda C, pump gas

phat lines are the 3,5i strocker and the slim lines are the ITB engine with 3,2. VTEC is late, at about 6800, cause before the power would suffer. We tested it of course.

I think the difference is just the use of imperial vs. metric horsepower ratings and/or how the dyno's software calculates ps and torque.

I remember my engine and ITB tuning having to take a while as well. At least I think I remember that way. You could probably get a few more hp if you used a higher octane fuel. That a possibility?

I use 100 Octane, you can get them pretty much everywhere at Shell, OMV, etc. Aral has 102 Octane, but only in Germany.

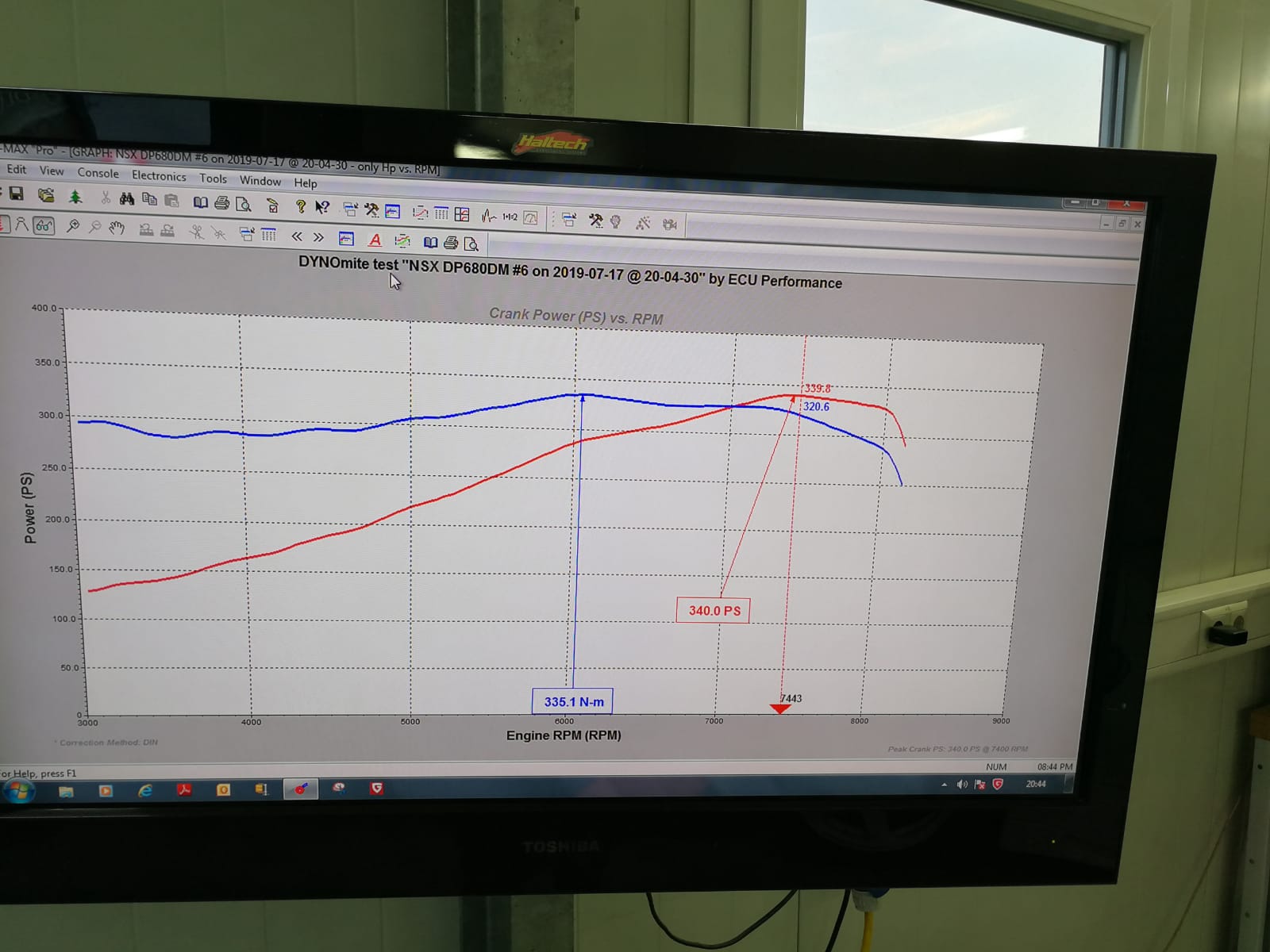

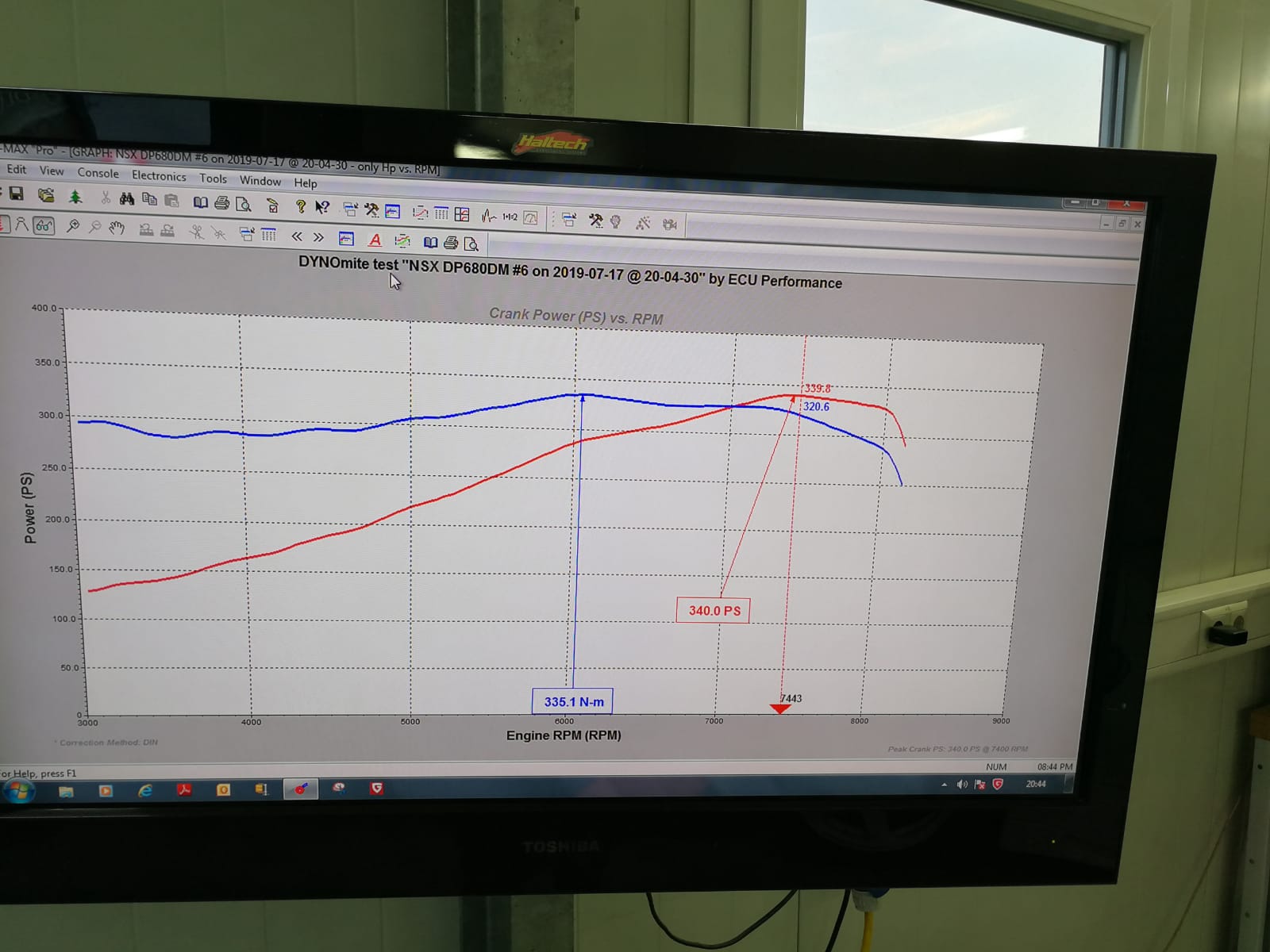

Another ITB customer from ATR racing - AUSTRIA (Europe). 340 HP to the flywheel and 335NM

built 3,0 with 11,5:1 pistons, ADAC GT high lift cams (moderate, similiar to Comptech), SoS ITBs, AEM V2, Comptech headers.

built 3,0 with 11,5:1 pistons, ADAC GT high lift cams (moderate, similiar to Comptech), SoS ITBs, AEM V2, Comptech headers.

Christian, how are you doing the airbox? Carbon fiber?

IN THE MIX; HAYWARD ITB & REVERIE AIRBOX (universal Hockenheim) feat. ATR RACING modification.

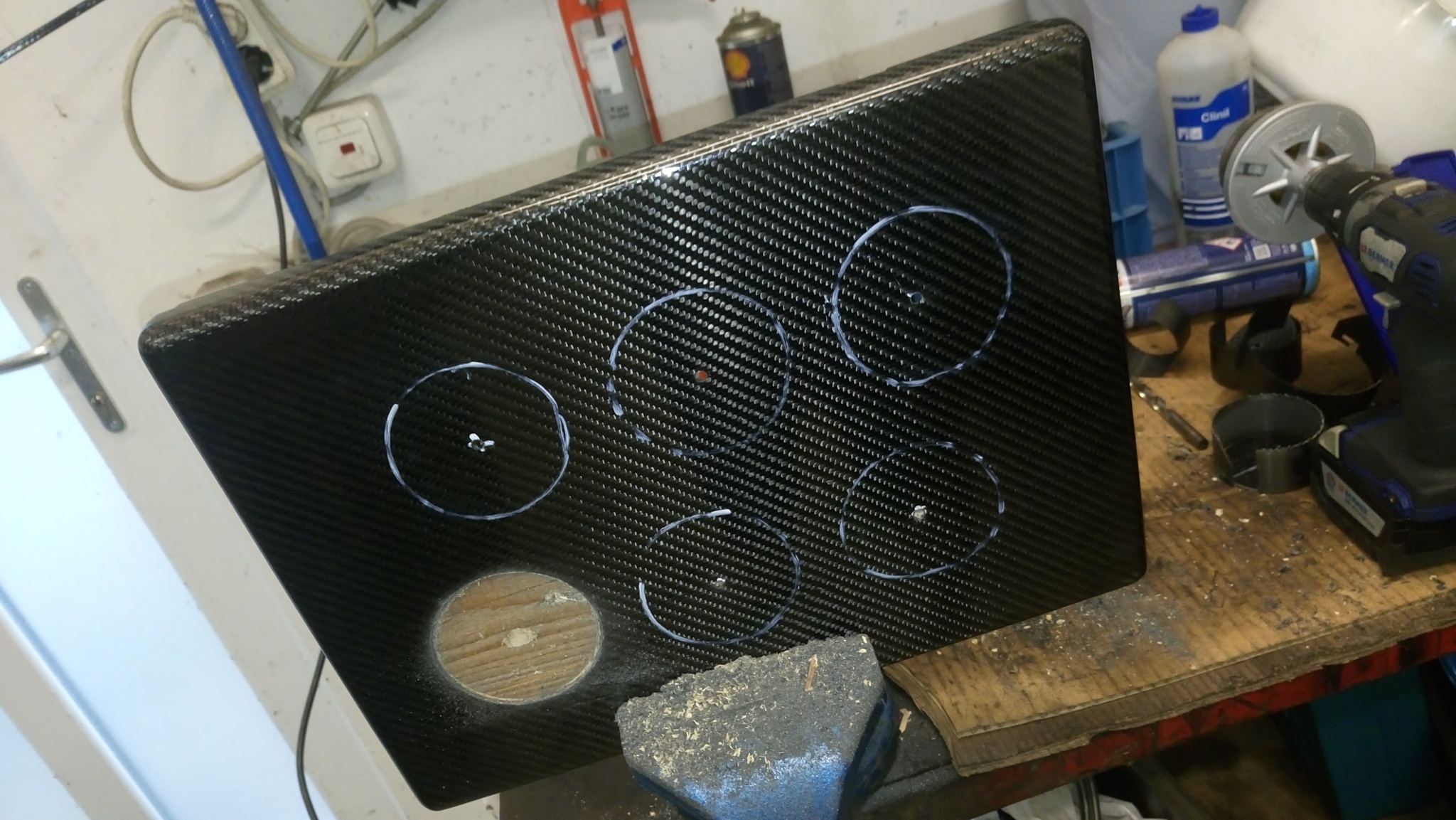

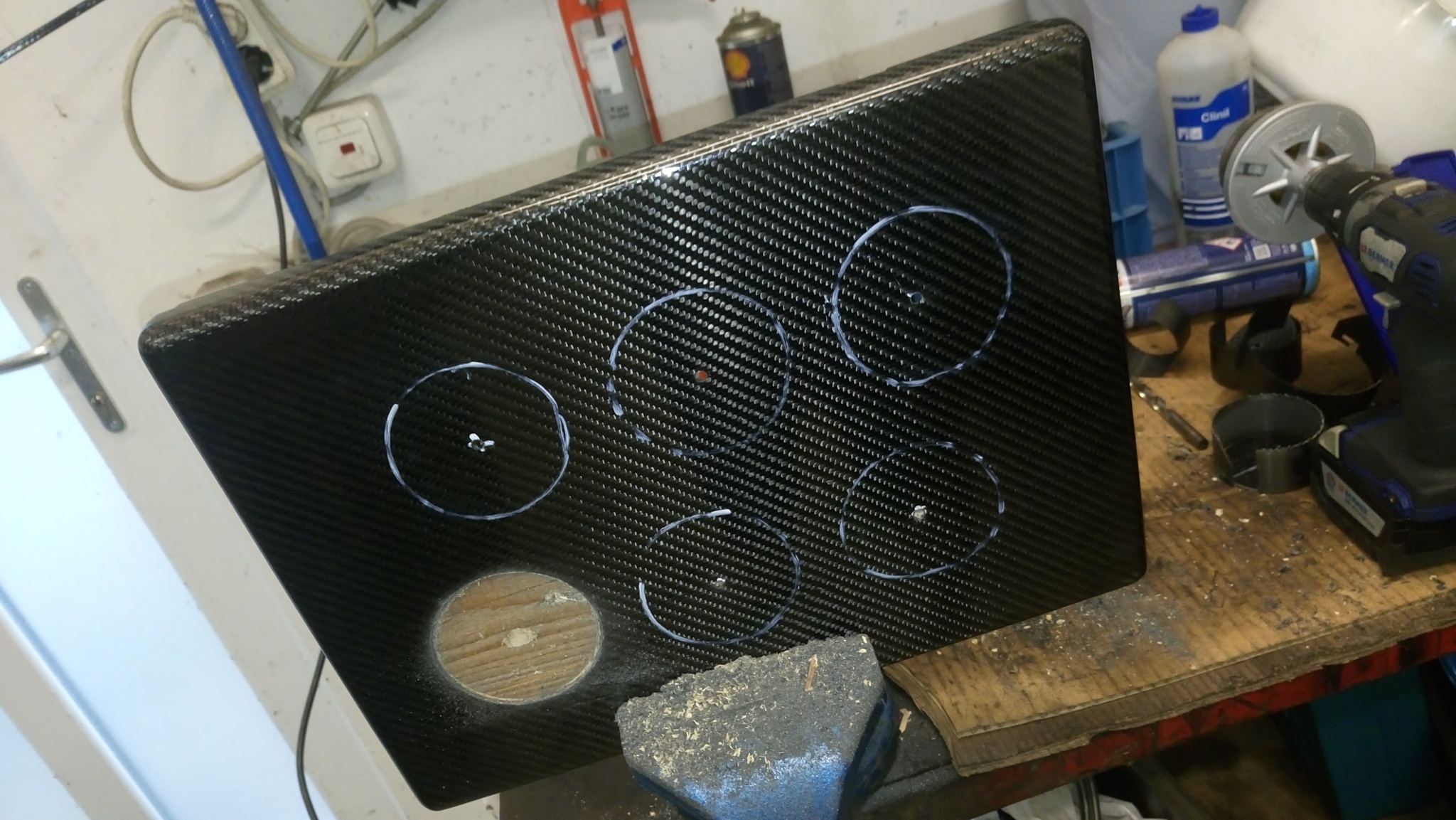

In the past days I bought me some special trumpet grommets and a 80mm driller. The biggest grommets I found was too small in diameter to put it nearly on top of the Jenvey funnels, so I had to cut some of the rubber off and use ~1,2 grommets to get the full circum.

In the first pic you see a standard cf plate which I used for testing. Then I transfered the holes onto the CF bottom cover. I made "service holes" to have access to the screws for the trumpts. I closed those with grommets. The next steps are to cut the top box cover to not hit the glas. It will be cuted in a 30 degree angel about. Then I will cut out a hole and glue on the back plate with 100mm duct for fresh air feed. Then put back the intake air temp sensor somewhere in the box.

I use for 60mm long trompets on the outer cylinder and 70mm long trompets on the middle cylinders. The TB and trompet diameter is 52mm

Thuesday is Dyno day. I should see 25-30hp in the midrange and 10-15hp at top end with this setup....at least I hope.

In the past days I bought me some special trumpet grommets and a 80mm driller. The biggest grommets I found was too small in diameter to put it nearly on top of the Jenvey funnels, so I had to cut some of the rubber off and use ~1,2 grommets to get the full circum.

In the first pic you see a standard cf plate which I used for testing. Then I transfered the holes onto the CF bottom cover. I made "service holes" to have access to the screws for the trumpts. I closed those with grommets. The next steps are to cut the top box cover to not hit the glas. It will be cuted in a 30 degree angel about. Then I will cut out a hole and glue on the back plate with 100mm duct for fresh air feed. Then put back the intake air temp sensor somewhere in the box.

I use for 60mm long trompets on the outer cylinder and 70mm long trompets on the middle cylinders. The TB and trompet diameter is 52mm

Thuesday is Dyno day. I should see 25-30hp in the midrange and 10-15hp at top end with this setup....at least I hope.

customized the box. Cutted into the right angle to give me most volume. Glued the funnel onto the backplate. VOlume is now 14 Liter.

I have an ITB set for sale in classifieds if anyone's interested.

I have an ITB set for sale in classifieds if anyone's interested.

Still available?

Still available?

Sold a while back but working on a ground up design and nearly complete

Sold a while back but working on a ground up design and nearly complete

so cool you are working with Adnan half a world away....

At first it was difficult considering the pandemic shutdown pretty much had us all on edge worldwide, but after getting comfortable with all the remote working tools at our disposal it has become quite efficient!so cool you are working with Adnan half a world away....

For example, if he has changes in the CAD. I can just print them up here and test. Here's a crude example of a set of trumpets i'm currently printing to check not only performance, but clearance issues and what not.

(forgive the messy prints. these are at low quality and fast)

Similar threads

- Replies

- 19

- Views

- 8K

- Replies

- 43

- Views

- 3K

- Replies

- 56

- Views

- 13K

- Replies

- 691

- Views

- 188K