- Joined

- 13 February 2023

- Messages

- 49

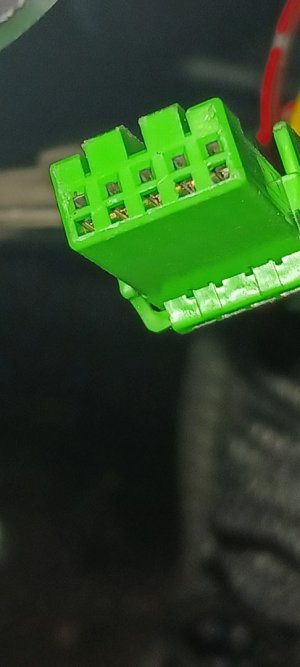

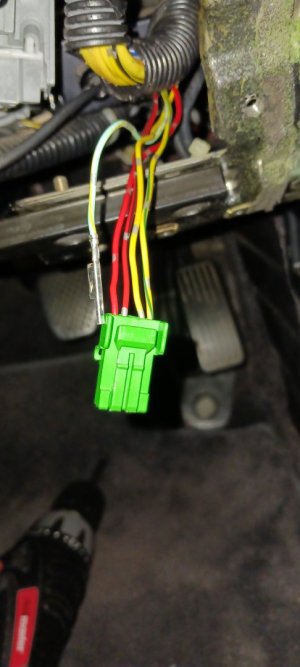

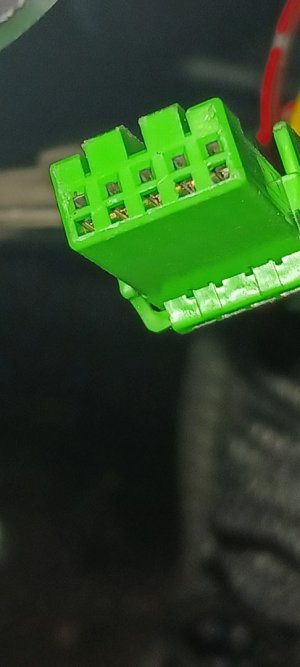

Does anyone here know how to remove and replace the wires in this plug? It goes to the TCS switch. The switch only works when I hold the wires at a certain angle. The problem is not the jack (female plug) on the switch housing. It is the wires going into the plug. I want to remove, clean and re-seat.

Thanks, Dan

Thanks, Dan