IIRC, scorp965 also had this happen to his.

If I weren't removing my VVIS for boost, I would put some tack welds on those screws.

Dave

If I weren't removing my VVIS for boost, I would put some tack welds on those screws.

Dave

wow...... talk about feeling uneasy. I have a 96 with a moderate amount of miles. Should I yank it right away?

IIRC, scorp965 also had this happen to his.

If I weren't removing my VVIS for boost, I would put some tack welds on those screws.

Dave

wow...... talk about feeling uneasy. I have a 96 with a moderate amount of miles. Should I yank it right away?

He's boosted so he can free up 1, maybe 2 hpWait until we see if the bore scope works :smile:.

He's boosted so he can free up 1, maybe 2 hp

I was kidding. sorry.. bad joke. Yes, you should remove it before you have Dave tune it.I've heard of 20-30 hp increase with boosted applications.

Peace of Mind

over

Power

No need to rip apart the intake. A generic 18" or longer borescope will work fine for inspection, no special mirrors or attachments are needed. I have a cheap fiber optic one, however I'm going to order an even cheaper $20 USB one off ebay to see if that will be just as good.

Attached are photos, I know they are horrible but with a little patience you can see both sides of the plates clearly. In all it took me 20 minutes to inspect all 6 plates. My screws seem to be fine, but my borescope didn't have enough resolution to see how pronounced the swage was.

I took a couple photos from my cell phone, so it's not good quality at all, but you get the idea.

Left is a distant shot, right image is seriously "up close and personal" to the screw.

That is great! I take it you left the throttle body in place?

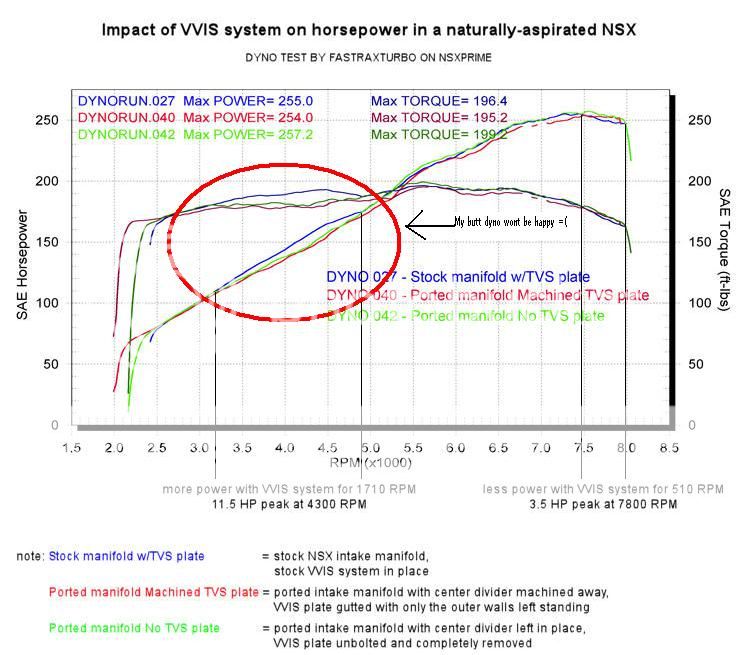

I've asked this here: http://nsxprime.com/forum/showthread.php?t=154928

but really should address it here. By removing the entire VVIS assm, can a plenum spacer in place pick up some lost torque on an NA car?

Guys, guys I went to the garage and checked the tire pressure on my tires... one was low, so I took it to a tire place and they said there was a nail in it... in a couple of days it would have gone flat.

You all should go out to the garage right away and remove all the tires from your cars and have them checked for nails otherwise one might go flat when you're driving fast and cause a serious accident in which several people could be killed.

Just sayin'

Makes perfect sense. Different metals expand and contract differently when heated and cooled and the engine vibration makes the screws loosen over time as they expand and contract. UHG! So far we have years: 1995, maybe 1996 and 1997. Any others?