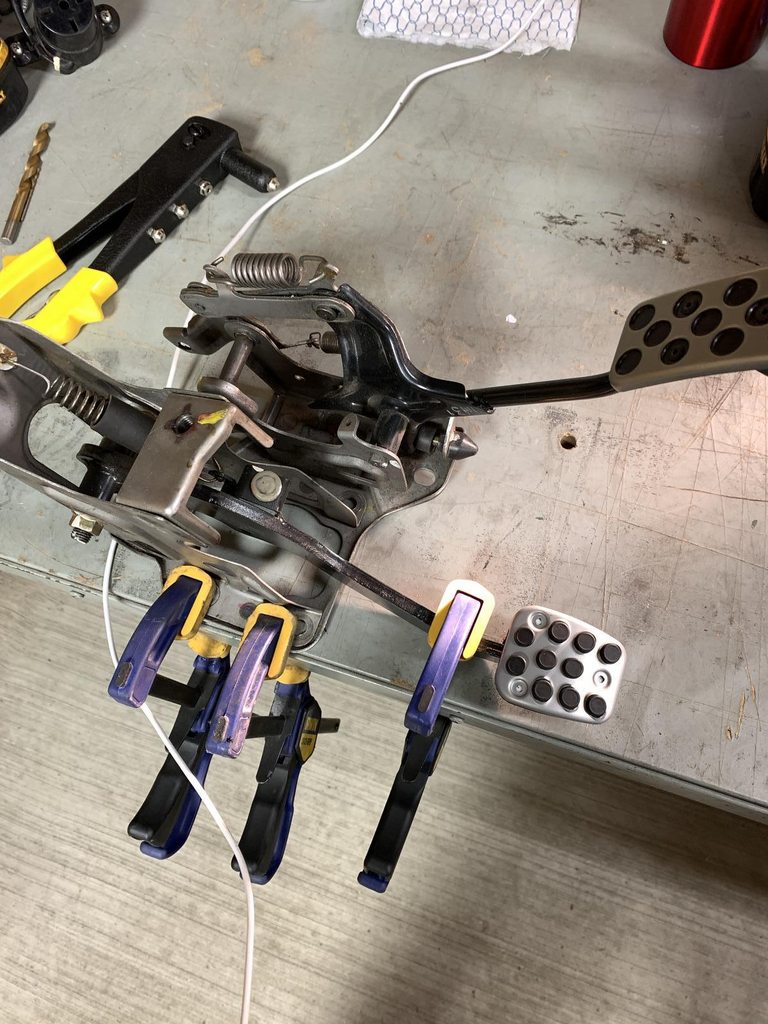

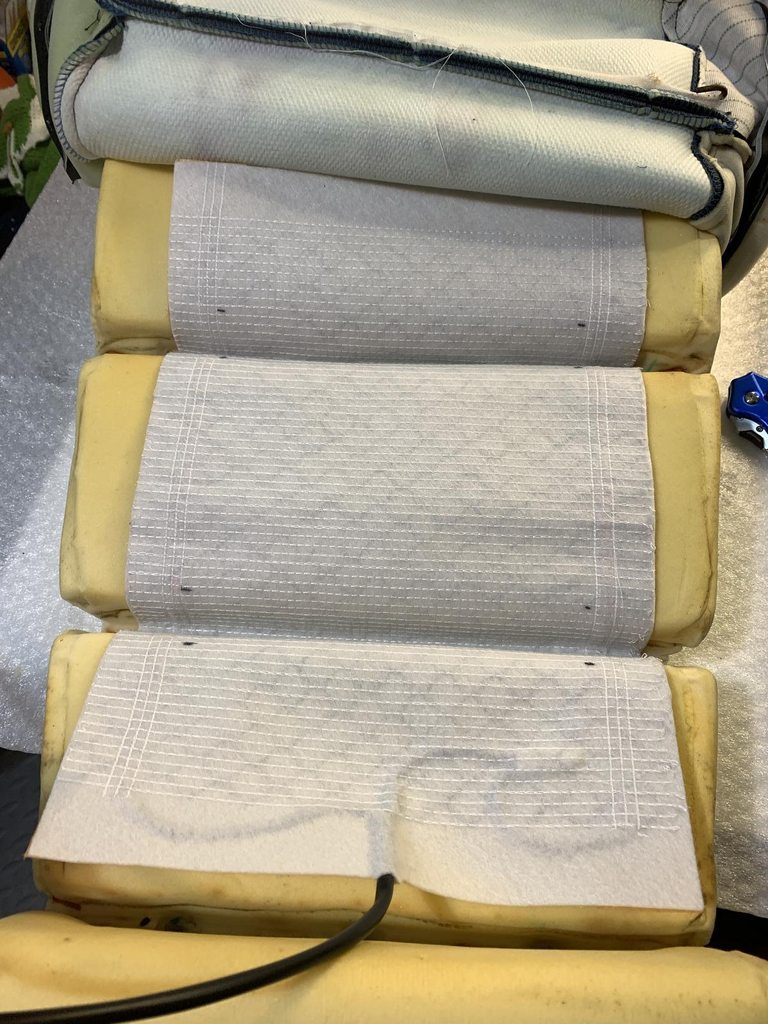

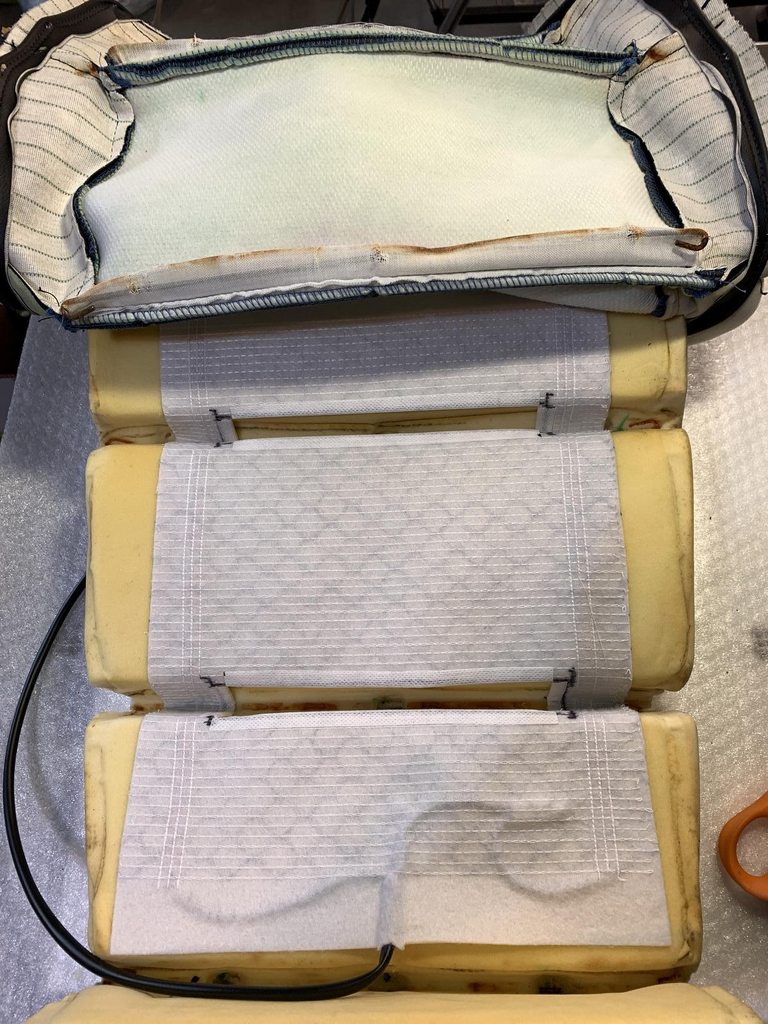

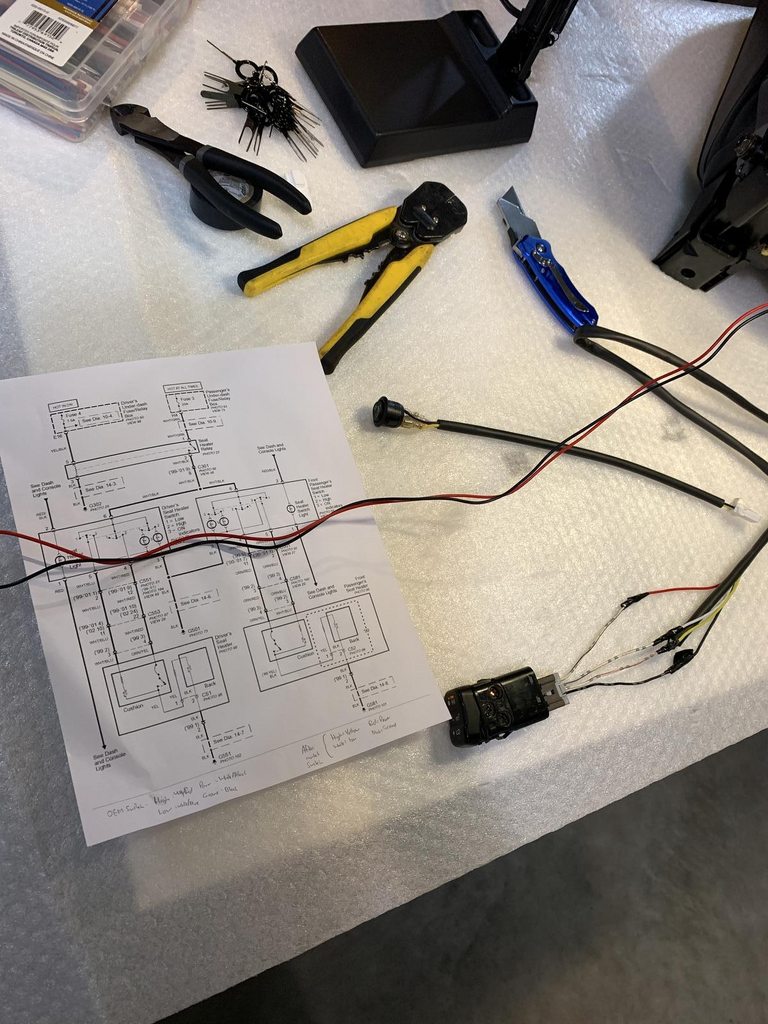

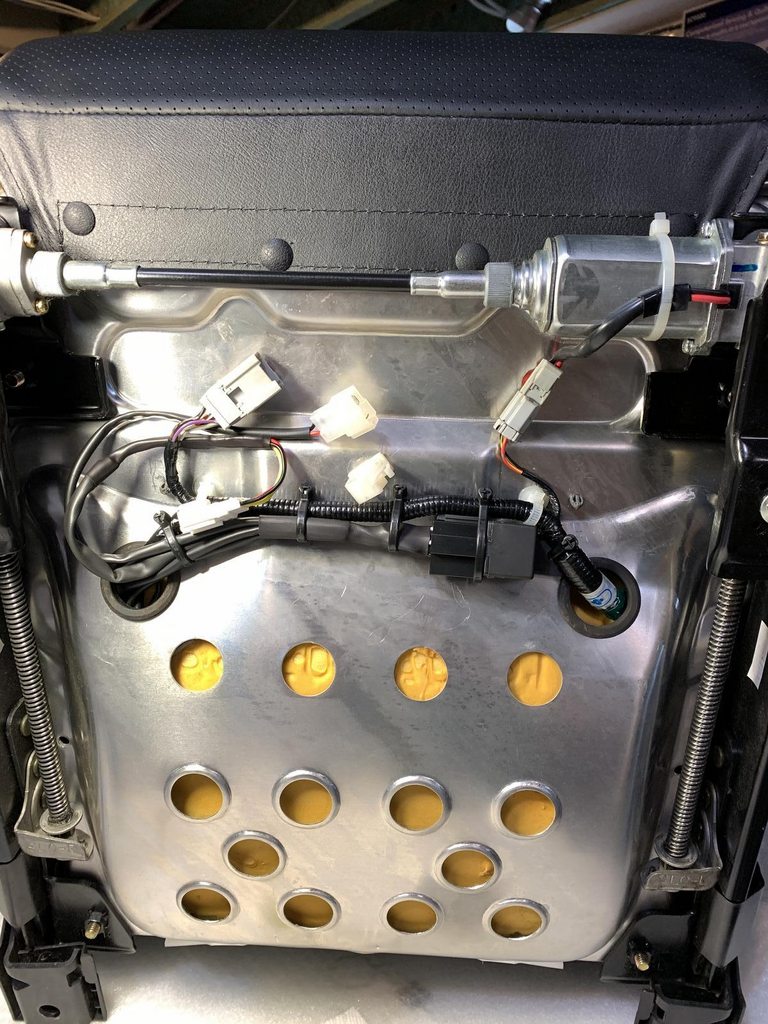

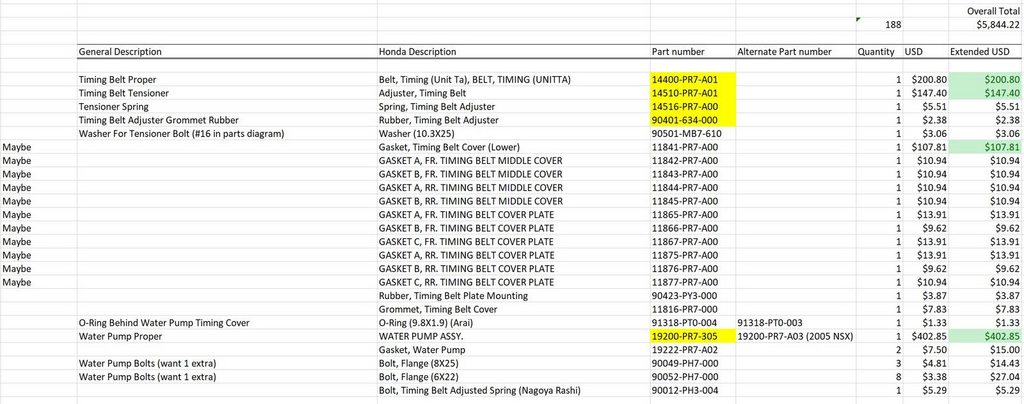

I’m preparing to do my timing belt and water pump. I’m way overdue on the belt as the service life is 7 years and mine is now 16 years old (nearly 17). I procrastinated quite a bit over the past few years avoiding the timing belt and did fun mods instead like NSX-R pedals and heated seats (I had the switches in a while ago but not the elements). I’ll post a few pictures of those but I’m mainly interested in your opinion on my parts list and if I missed anything timing belt/water pump related.

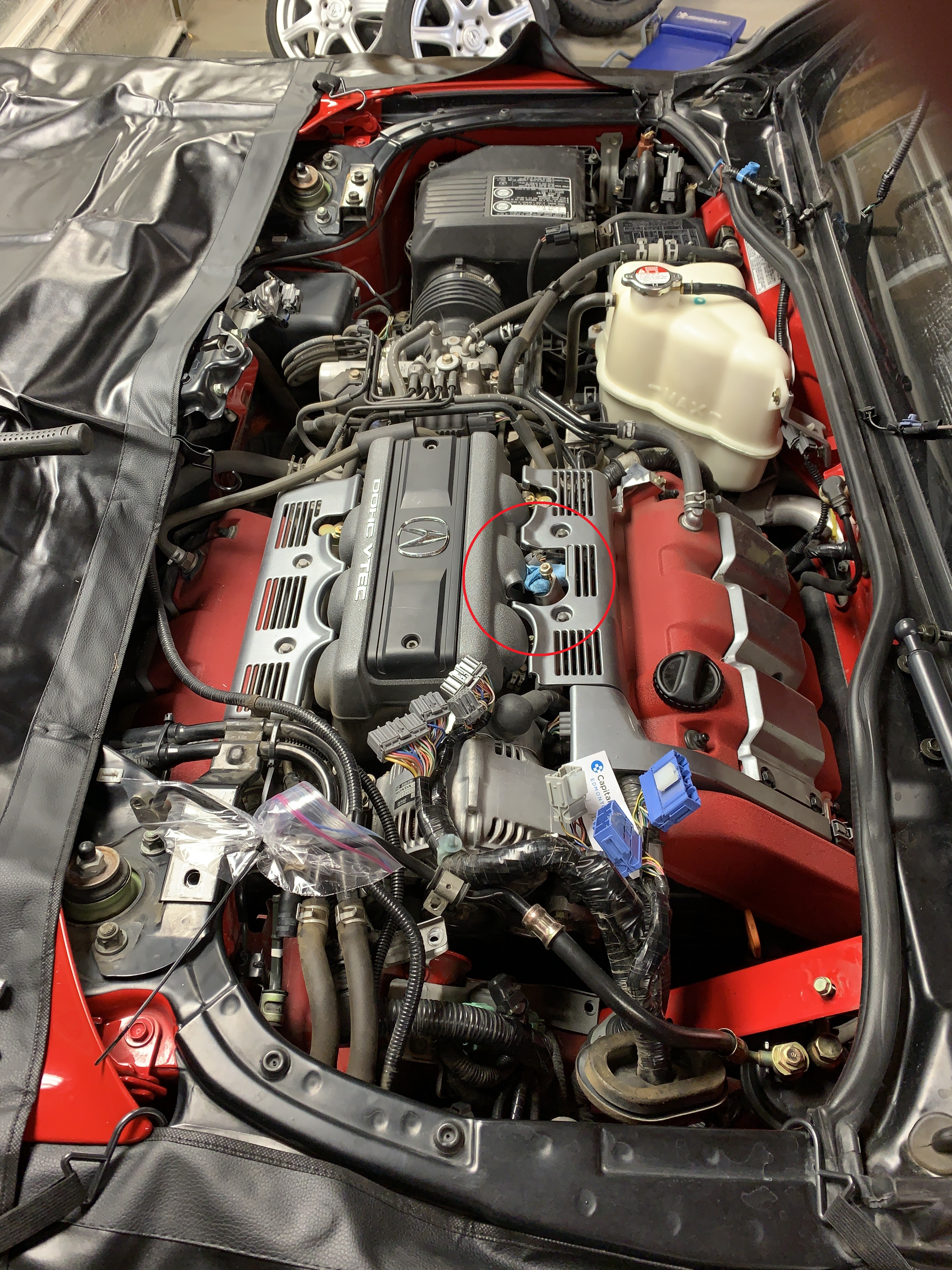

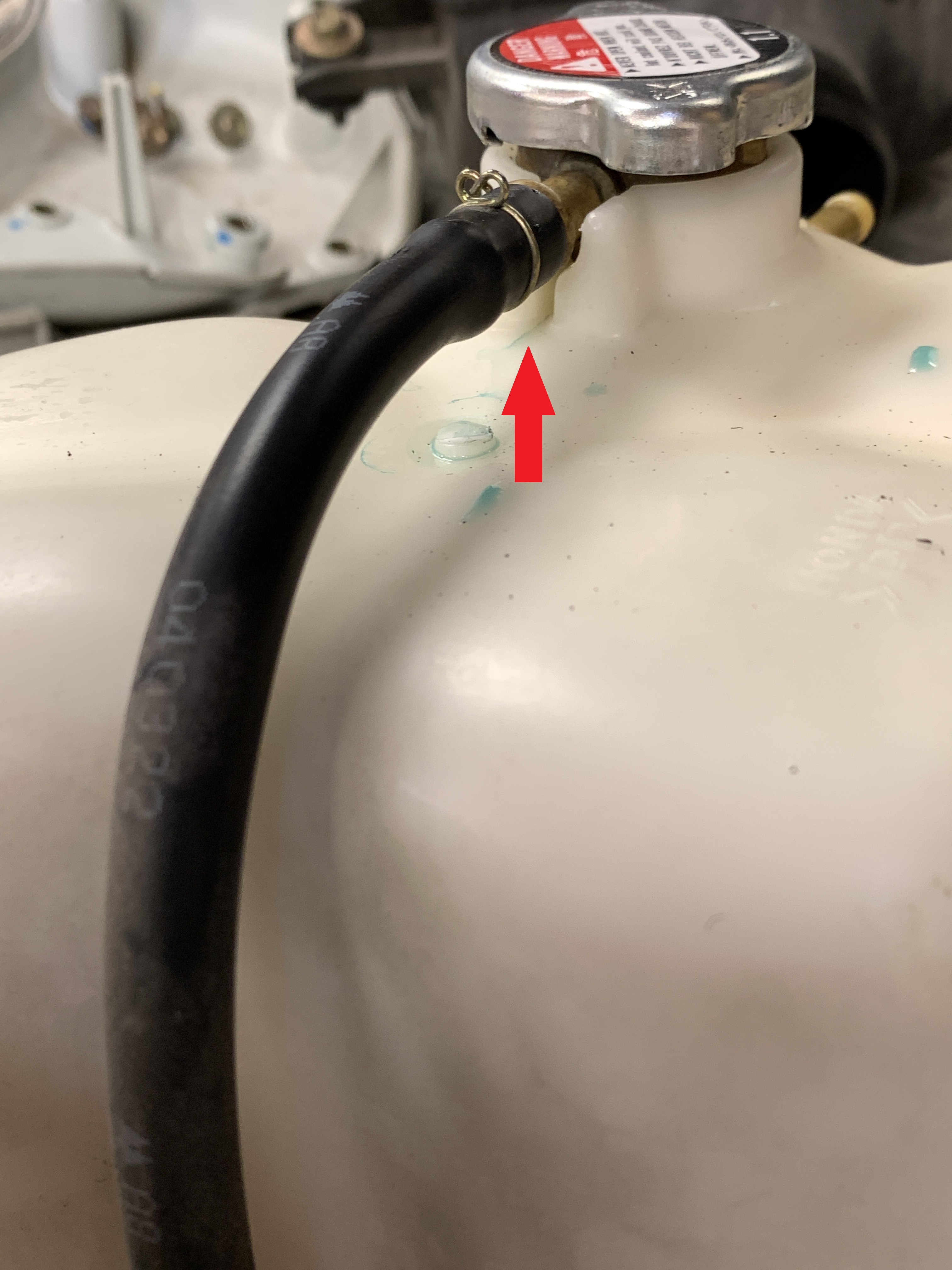

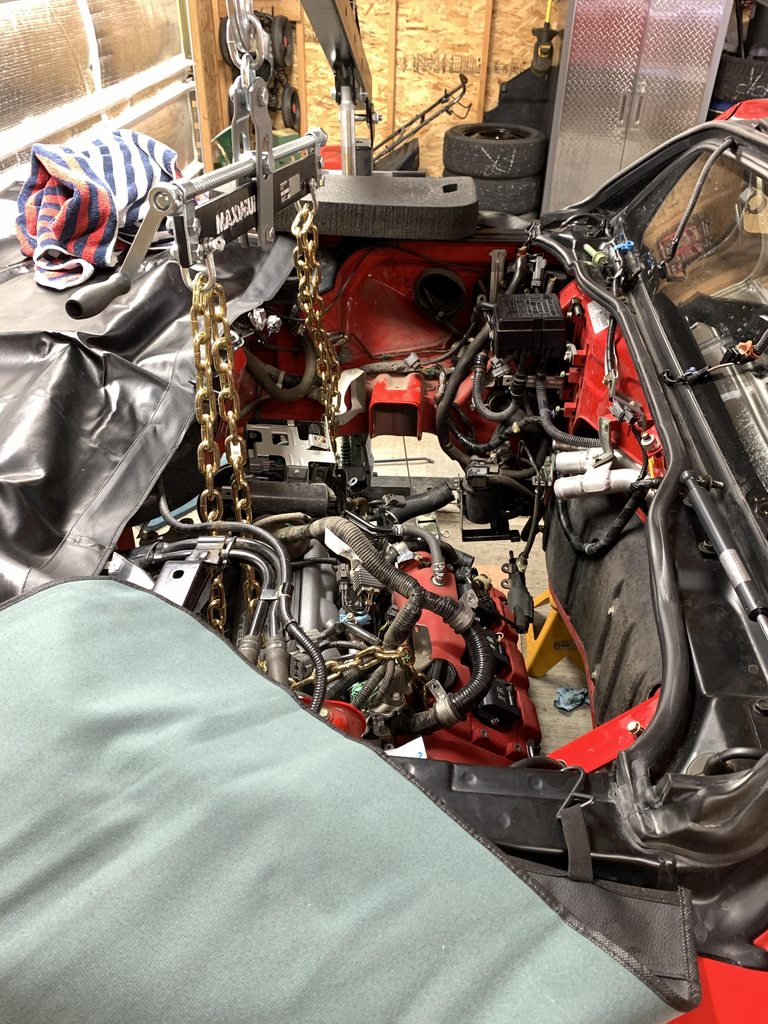

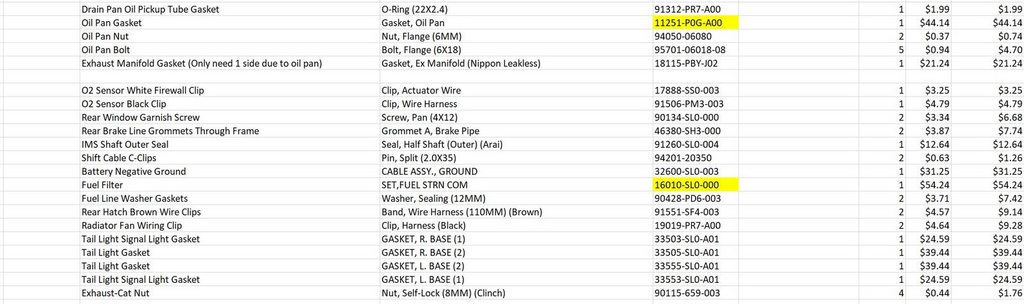

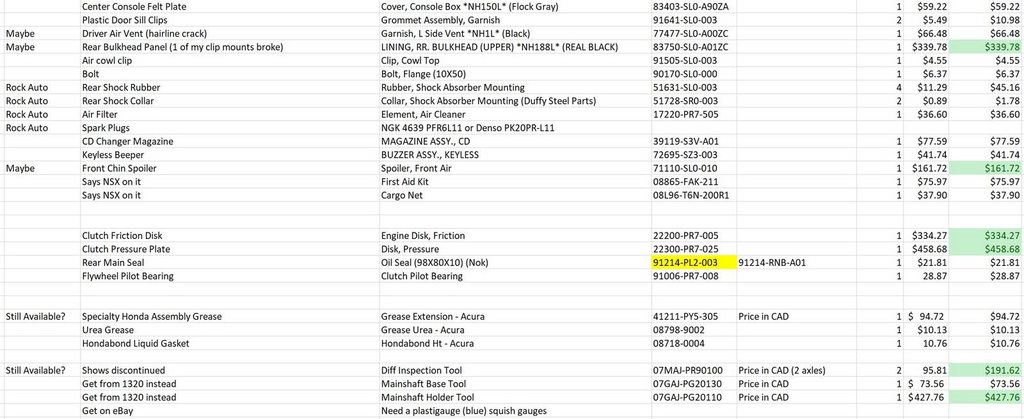

I’m planning to change everything that I see that’s easy to do while the engine is out (VTEC gaskets, coolant hoses, install an oil pan baffle, etc.). Some of the parts broke when I took them off so that’s why there are random little things like oxygen sensor clips and wire harness clips on the list. Then just some refresh items like rear taillight gaskets and new battery cable.

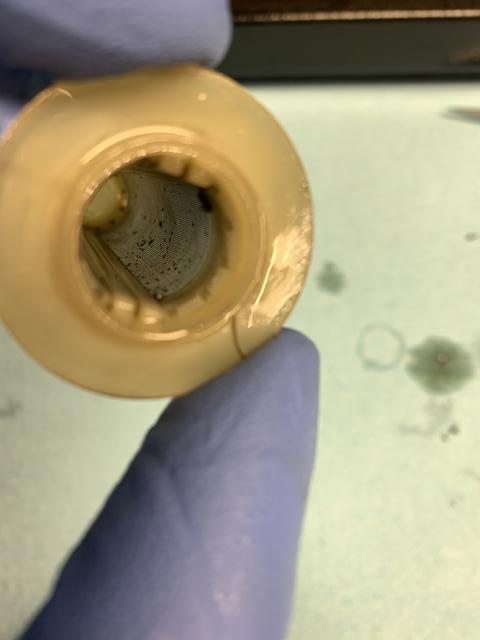

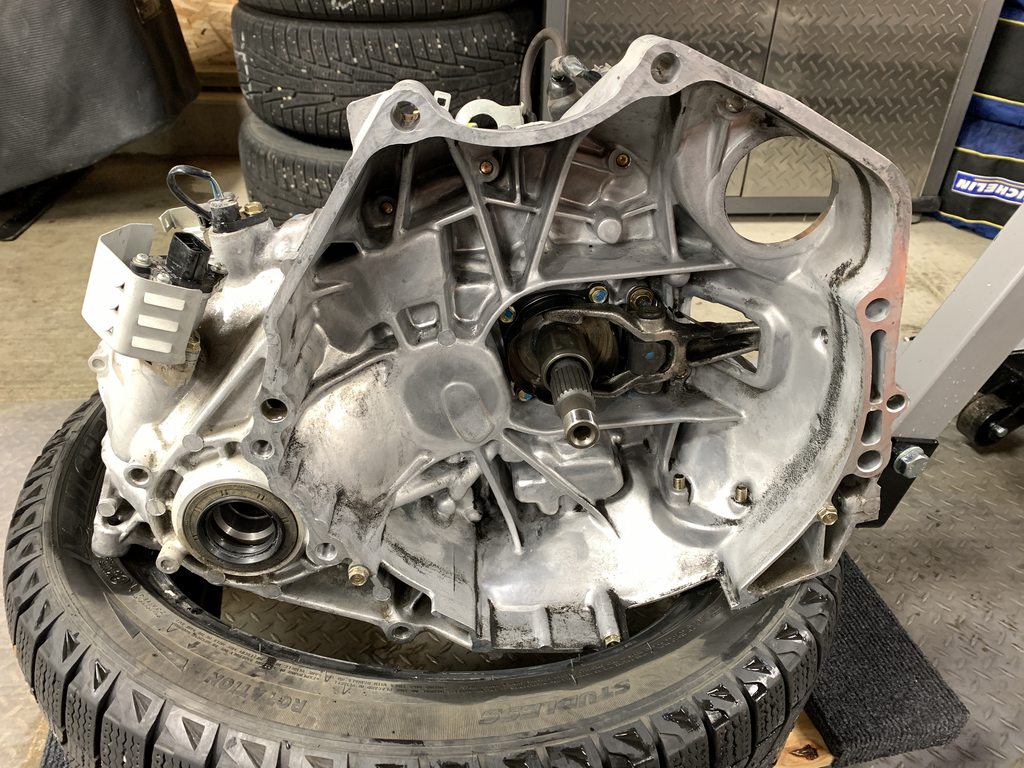

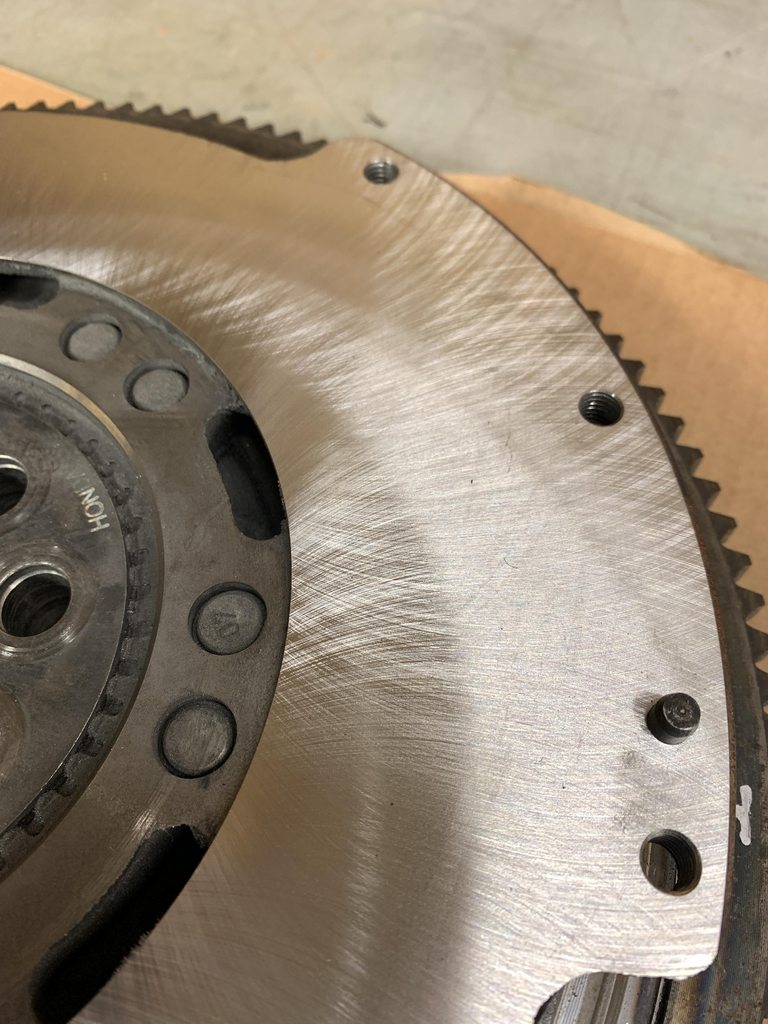

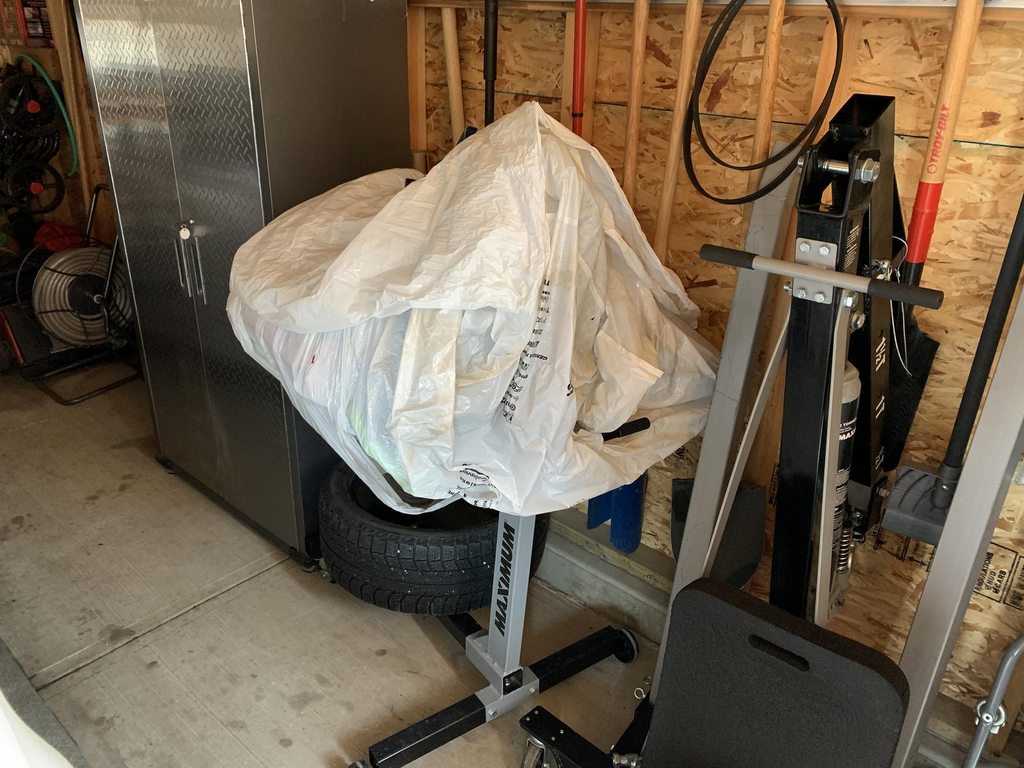

In the pictures below my main reason for pulling the transmission is I have to go through the synchros (maybe bearings) as I had a Spoon magnetic drain plug break off inside the transmission. I found little pieces of bearing in the fluid so with the timing belt due I figured I’d pull the transmission and rebuild it especially while all the parts are still available from Honda.

I’m planning to change everything that I see that’s easy to do while the engine is out (VTEC gaskets, coolant hoses, install an oil pan baffle, etc.). Some of the parts broke when I took them off so that’s why there are random little things like oxygen sensor clips and wire harness clips on the list. Then just some refresh items like rear taillight gaskets and new battery cable.

In the pictures below my main reason for pulling the transmission is I have to go through the synchros (maybe bearings) as I had a Spoon magnetic drain plug break off inside the transmission. I found little pieces of bearing in the fluid so with the timing belt due I figured I’d pull the transmission and rebuild it especially while all the parts are still available from Honda.