I recently bought 02+ NSX-R gauges and circuit boards but haven't installed because I want to have the shift lights working and programmable. I know at one point Pro Car had a little box you can plug in and set all the parameters. Does anyone know where i can find one of these or have another idea on how to make the shift lights operable?

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

02+ NSX-R Shift Light Programming Help

- Thread starter Re<<1

- Start date

The actual light operation is hard coded into the NSX-R ecu and is rather complicated. When the solid light/flashing light comes on and for how long is set for each gear and is different for each gear. IIRC, the aftermarket options like the Procar box had only one operation, so you can get a flashing light at a certain RPM, but that's all. I might be wrong though.

Translation

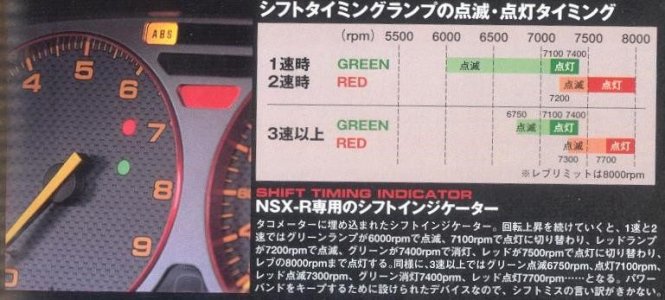

The left vertical column says 1st gear, 2nd gear, 3rd gear and up.

In first gear, soft green light will emit from 6000rpm-7100rpm, intense green light will lit from 7100rpm-7400rpm.

In second gear, soft red light will emit from 7200rpm-7500rpm, intense red light will lit from 7500rpm-8000rpm.

For 3rd gear and up, soft green light from 6750rpm-7100rpm, intense green light from 7100rpm-7400pm. Soft red light from 7300rpm-7700rpm, intense red light from 7700rpm-8000rpm.

Shift timing indication, exclusively on the NSX-R.

Shift points are set from the factory, not adjustable.

worthless mod. i asked procar for this before, which cost 4k for cluster color change.

It is doable to mimic the OEM system. You would need to fab up a logic circuit with inputs based on rpm and wheel speed, with outputs going to the tach board. You'd probably have to use an auto trans tach board, as it has the led lights in the correct spot for the R cluster lights and pinouts on the green harness for the led lights. Then, you would need to program the same ranges into the circuit as in the chart linked above. There are probably several Prime members with that level of computer/elec engineering skill. Just gotta find them and convince them to do it.

It is doable to mimic the OEM system. You would need to fab up a logic circuit with inputs based on rpm and wheel speed, with outputs going to the tach board. You'd probably have to use an auto trans tach board, as it has the led lights in the correct spot for the R cluster lights and pinouts on the green harness for the led lights. Then, you would need to program the same ranges into the circuit as in the chart linked above. There are probably several Prime members with that level of computer/elec engineering skill. Just gotta find them and convince them to do it.

Haha yea you're right! I understand the concept enough to make a valid attempt. All you need is the tach output signal, ground, power and some sort of DIP switch to set you shift light parameters. What i don't know is the exact power levels and wiring. So what resisters and other electronic components do I need to make everything operate correctly and safely.

The hardware pieces may be pretty simple. Depending on which one board controller you use, you may not need any external components if the circuit boards for the R cluster already has internal voltage dropping resistors for the shift LEDs. That would not surprise me since the ECU probably ground switches the LEDs. An Arduino Uno is limited to 40 mA on its digital outputs which is likely below the LED current; but, you can probably find a one board controller with adequate current sinking capability.

Calculating steady state RPM with an engine pulse output is pretty trivial. Accurately calculating RPM during fast acceleration is non trivial as you need to incorporate first and second differentials for the time between tach pulses otherwise your calculation will always lag behind the actual RPM. A little more coding work. The more interesting problem is the gear selection since I don't recall any shift position indication for the standard transmission. You could generate an inferred gear selection in software by picking up a vehicle speed signal and dividing it by RPM to calculate the overall gear ratio - perhaps what [MENTION=18194]Honcho[/MENTION] was referring to when he mentioned wheel speed. Should go without saying that you need to write your code so that you don't generate a divide by zero if you rev your engine with the vehicle at rest.

The hardware may be relatively easy. The software not so trivial unless you are moderately proficient in coding.

Calculating steady state RPM with an engine pulse output is pretty trivial. Accurately calculating RPM during fast acceleration is non trivial as you need to incorporate first and second differentials for the time between tach pulses otherwise your calculation will always lag behind the actual RPM. A little more coding work. The more interesting problem is the gear selection since I don't recall any shift position indication for the standard transmission. You could generate an inferred gear selection in software by picking up a vehicle speed signal and dividing it by RPM to calculate the overall gear ratio - perhaps what [MENTION=18194]Honcho[/MENTION] was referring to when he mentioned wheel speed. Should go without saying that you need to write your code so that you don't generate a divide by zero if you rev your engine with the vehicle at rest.

The hardware may be relatively easy. The software not so trivial unless you are moderately proficient in coding.

Similar threads

- Replies

- 9

- Views

- 422

- Replies

- 9

- Views

- 814

- Replies

- 6

- Views

- 680

- Replies

- 6

- Views

- 310