Well, seems like nothing can go right for me.

Last night I got the car to the dyno finally, we strap the car down , and Marco at Magnus got to work.

I was most worrie about start up and with AEM little did I know what I had coming.

Marco's work start coming trough, one crank start and idle perfect!!!

Then he start doing advance tuning, First pull boost goes trough the roof @15 PSi!!! With the AEM Tru-boost off, so the Marco ask me what size spring was in the wastegate and I respond 3psi, then he ask me to run the compressor straight to the gate and bypass the controller, so I did.

Does another run, and we have 10.3psi with a wastegate controlled boost that is only running a 3psi spring.

Finally Marco comes out of the car, goes underneath the car and this is how the conversation went:

Marco:what da fak is this and why is like this???

Me:what???

Marco: the wastegate desing is running the wrong way!!! And it not releasing boost efficiently .

Marco: let me explain this way, exhaust need something like a highway off-ramp not a hairpin where it actually has to even turn around!!!!

Me: but there....

Marco: ya ya ya, there is 20 kits out there and this has never happened... Well it's happening now. Plus the pipes for the wastegate are to small in diameter for this wastegate .

Me: Fack.

I understand that there is all of you guys running this kit with this desing and has had no trouble, I think upgrading my wastegate to a precision unit has brought up the problem stated above.

The Y-pipe will be coming out tonigh, I'll mock up where the wastegate should come out and hopefully be back on the dyno on Saturday .

This is our theory, I will let you know guys if that fixed the problem, btw wastegate is working just fine.

If you have an idea of why this may be happening I would like to hear it.

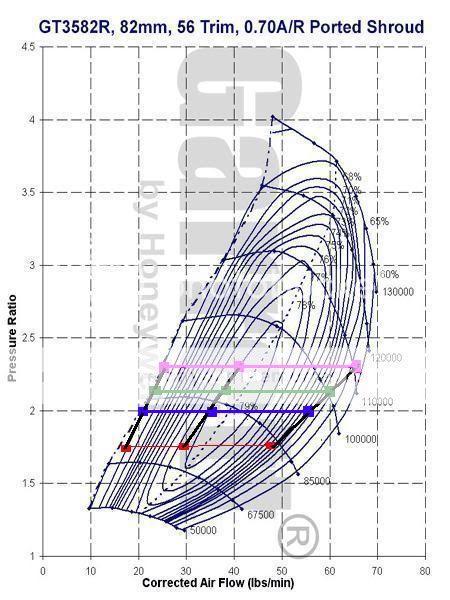

Here is what Marco is talking about.