My 91 NSX started having issues with the AC, where sometimes the compressor wouldn't come on when commanded and would stay on when I turned it off (the compressor itself, not just the fan). Also, the condenser fans would come on sometimes when the AC wasn't on. The consensus seems to be the fan control unit failing, so I took it apart to see what was wrong. From a first glance, the electrolytic cap seems to be bulging:

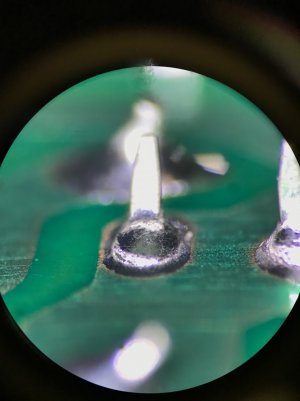

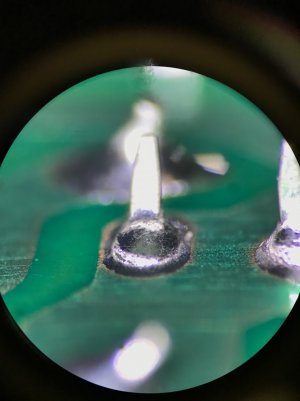

Upon further inspection with a microscope, it also seemed that some of the solder joints were cracking:

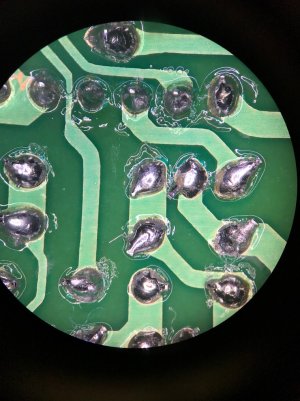

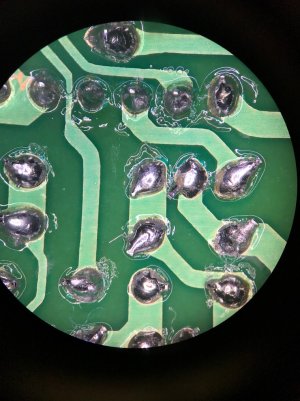

I replaced the capacitor with a 5000-hour rated part (Digikey P14373-ND, $0.21) and reflowed the joints with a soldering iron, adding a little flux-core solder in the process to break the surface tension. Note that half the board is conformal coated, but I was still able to solder through it. Initial tests today seem to be promising, in that all the fans were off initially and turned on when they were supposed to. I need to do some more testing, but I'm fairly confident this will solve the issue. Took maybe an hour or two and $0.21. See below for re-flowed joints, hope this is helpful to someone else in the same boat.

Upon further inspection with a microscope, it also seemed that some of the solder joints were cracking:

I replaced the capacitor with a 5000-hour rated part (Digikey P14373-ND, $0.21) and reflowed the joints with a soldering iron, adding a little flux-core solder in the process to break the surface tension. Note that half the board is conformal coated, but I was still able to solder through it. Initial tests today seem to be promising, in that all the fans were off initially and turned on when they were supposed to. I need to do some more testing, but I'm fairly confident this will solve the issue. Took maybe an hour or two and $0.21. See below for re-flowed joints, hope this is helpful to someone else in the same boat.

Last edited: