Some may not know who is operator so may i

Re Introduce / background about AMW Dyno Service ( AKA operator)

My name is Juha Martikainen (age53) and i run speedshop AMW Dyno Service founded 1994.

i have been working with cars/engines since i was a kid .

Education is macinist/ technical engineer . Before to come full time self employee I was working

in insulation factory as maintenance supervisor. We have two dynos 4x4and big roll 2WD

both are done in house. Electronics are from TAT /germany. We are involved street,track,rally,rallycross and well almost all kind of motorsport. We have been building engines and all kind of car metal parts over 30 years so we dont get confused if someone says it cant be done. More info you can find here :http://amwdynoservice.com/

MAX effiency build :http://www.nsxprime.com/forum/showthread.php/198506-Max-effiency-turbo-build

I think most sceary thing what coud happen to your C30A engine is rod bearing fairule ( bearing spun). It will destroi your crankshaft rod journal pin and rod big end bore. It may scratch you cylinder wall or piston and Oil pump too.

These crankshaft /rod damages can be fixed in certain limits !

Why bearing gets damaged ?

-Lack of lubrication is main reason. And it is caused from following reasons

-No oil pan pafle

-in correct oil wiscosity at running temp

-poor oil quality

-low oil level

-Some crankshaft /bearing/oil suply desing related problems in C30A

All these we can discus later on.

First to able to refurbish your crankshaft you need undersize bearings what you cant find from honda. We manage to get good quality bearings preforms what we modify for our needs.

These bearings can handle more pressure than honda OEM.

Crankshaft goes tru 14 steps during recontioning service ! Lets make short look of those steps:

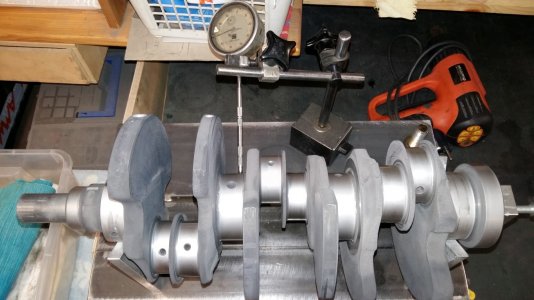

-Crank comes in we measure damaged journal and rest of journals ( look min dimensions on following text) runout check ( MAX runout 0,15 mm) and type of damage.

-Dye inspection for cracks , now we have good idea what kind of service this crank needs.

-Run out fix

-Rod big end bore fix . If damage is very small. Bad > better get undamaged rod/piston

-crankshaft re-grinding /polish > look cases

-crankshaft Nitrocarburation(NC) what is one of the best method for these kind

of good quality steel forgings. Crankshaft re polish after NC

-Crank and rod bearing clearance matching

This is very high presision work ! There is 4 companies involved in this refurbish proses.

it took 5 months of developing time to go tru this and finaly we magage to do it !

I have put together following real exsamples about this service

However there is limits what we coud do.

Stock Rod end bore is 53.00-53,03mm MAX 53,05mm NO colour chance or bad scoring marks

Crank pin OEM size is 50.00mm Minimum size what can be repaired is 49,65 mm (bea49.500)

Crankshaft pin SIDE damage OEM 22,05-22,08 MAX 22,15 If there is colour ongrank i need picture

CASE1. (lucky ones) Spunned one conection rod bearing . MAINS are good and crank is straigh

(max runout 2-3 1/100mm. Manual says 6 /100 ..too much )

Crank is fixed mains are polished and measured , Spunned crank conectionrod journal is fixed and rest of journal measured. Rod big end is fixed

Shipped with All new rodb earings. ( one rod is undersize rest of are std ,+025 or –025 90 % ofcases they are std ) USE OEM or old main bearings.

Crank shaft is nitrocarburised.

Price1485€

CASE2 ( most common )

Spunned one conection rod bearing . Crank runout is over the limit ( 6/100)up to 15 1/100 mm. Crank straightening . Spunned crank conection rod journal is fixed and rest of journal measured / polished.Rod big end is fixed

Main journals are fixed ( re grinding –.25 or –50 mm )

Shipped with All Conrod/MAINbearings. ( one rod journal is undersize rest of are std ,+025 or –025 90 %of cases they are std )

Crank haft is nitrocarburised !

BLOCK MAY NEED crank main bore alighooning ! MAX tunnel size is 69,02 mm (it is good because block is never straigh after 20 years ? of run)

2350€

CASE 3 same as CASE 2 but all rod journals are grinded ( then all rod bearings are same size ! )

2560€

Options

-ROD big end re-contioning +190€ each (ONLY if more than one rod is gone )

-Extra rod journal grind 50€ (if more than one is gone) Not case 3 ,included

-AMW oil pan pafle 60€

-Only race bearings for six rods 470€ ( i need all rods ) This is just for duilders who wants

more durable bearings.

Recomended toda/comptech pump gearset or similar

For refurbish >

I need Crank, ALL rods. CASE 2 and 3 i woud like to know block main bore diameter !

All this comes with detailed manual and tips how to work with during your engine rebuild.

Re Introduce / background about AMW Dyno Service ( AKA operator)

My name is Juha Martikainen (age53) and i run speedshop AMW Dyno Service founded 1994.

i have been working with cars/engines since i was a kid .

Education is macinist/ technical engineer . Before to come full time self employee I was working

in insulation factory as maintenance supervisor. We have two dynos 4x4and big roll 2WD

both are done in house. Electronics are from TAT /germany. We are involved street,track,rally,rallycross and well almost all kind of motorsport. We have been building engines and all kind of car metal parts over 30 years so we dont get confused if someone says it cant be done. More info you can find here :http://amwdynoservice.com/

MAX effiency build :http://www.nsxprime.com/forum/showthread.php/198506-Max-effiency-turbo-build

I think most sceary thing what coud happen to your C30A engine is rod bearing fairule ( bearing spun). It will destroi your crankshaft rod journal pin and rod big end bore. It may scratch you cylinder wall or piston and Oil pump too.

These crankshaft /rod damages can be fixed in certain limits !

Why bearing gets damaged ?

-Lack of lubrication is main reason. And it is caused from following reasons

-No oil pan pafle

-in correct oil wiscosity at running temp

-poor oil quality

-low oil level

-Some crankshaft /bearing/oil suply desing related problems in C30A

All these we can discus later on.

First to able to refurbish your crankshaft you need undersize bearings what you cant find from honda. We manage to get good quality bearings preforms what we modify for our needs.

These bearings can handle more pressure than honda OEM.

Crankshaft goes tru 14 steps during recontioning service ! Lets make short look of those steps:

-Crank comes in we measure damaged journal and rest of journals ( look min dimensions on following text) runout check ( MAX runout 0,15 mm) and type of damage.

-Dye inspection for cracks , now we have good idea what kind of service this crank needs.

-Run out fix

-Rod big end bore fix . If damage is very small. Bad > better get undamaged rod/piston

-crankshaft re-grinding /polish > look cases

-crankshaft Nitrocarburation(NC) what is one of the best method for these kind

of good quality steel forgings. Crankshaft re polish after NC

-Crank and rod bearing clearance matching

This is very high presision work ! There is 4 companies involved in this refurbish proses.

it took 5 months of developing time to go tru this and finaly we magage to do it !

I have put together following real exsamples about this service

However there is limits what we coud do.

Stock Rod end bore is 53.00-53,03mm MAX 53,05mm NO colour chance or bad scoring marks

Crank pin OEM size is 50.00mm Minimum size what can be repaired is 49,65 mm (bea49.500)

Crankshaft pin SIDE damage OEM 22,05-22,08 MAX 22,15 If there is colour ongrank i need picture

CASE1. (lucky ones) Spunned one conection rod bearing . MAINS are good and crank is straigh

(max runout 2-3 1/100mm. Manual says 6 /100 ..too much )

Crank is fixed mains are polished and measured , Spunned crank conectionrod journal is fixed and rest of journal measured. Rod big end is fixed

Shipped with All new rodb earings. ( one rod is undersize rest of are std ,+025 or –025 90 % ofcases they are std ) USE OEM or old main bearings.

Crank shaft is nitrocarburised.

Price1485€

CASE2 ( most common )

Spunned one conection rod bearing . Crank runout is over the limit ( 6/100)up to 15 1/100 mm. Crank straightening . Spunned crank conection rod journal is fixed and rest of journal measured / polished.Rod big end is fixed

Main journals are fixed ( re grinding –.25 or –50 mm )

Shipped with All Conrod/MAINbearings. ( one rod journal is undersize rest of are std ,+025 or –025 90 %of cases they are std )

Crank haft is nitrocarburised !

BLOCK MAY NEED crank main bore alighooning ! MAX tunnel size is 69,02 mm (it is good because block is never straigh after 20 years ? of run)

2350€

CASE 3 same as CASE 2 but all rod journals are grinded ( then all rod bearings are same size ! )

2560€

Options

-ROD big end re-contioning +190€ each (ONLY if more than one rod is gone )

-Extra rod journal grind 50€ (if more than one is gone) Not case 3 ,included

-AMW oil pan pafle 60€

-Only race bearings for six rods 470€ ( i need all rods ) This is just for duilders who wants

more durable bearings.

Recomended toda/comptech pump gearset or similar

For refurbish >

I need Crank, ALL rods. CASE 2 and 3 i woud like to know block main bore diameter !

All this comes with detailed manual and tips how to work with during your engine rebuild.

Last edited: