Ok, yeah sorry my last message was all over the place. I had a million thoughts running in my head and I was multi-tasking at work before getting ready to shut down.

I think the best thing to do is bring it back to simple basics. You probably already know all of this, but I figured I'll start from scratch so this might be helpful for anyone following along and good for just a general refresher for me (it's been a while). (And also to retort to certain critics that claim I offer nothing of value except stupid cat pictures in the off topic forums). First let’s discuss the wastegate and how it works. You have two chambers in the wastegate. The first is where the boost pressure is basically “analyzed.” If the pressure is “acceptable” (below the spring rating), then it keeps a valve/plunger closed and allows all of the exhaust gasses to pass to the spool side of the turbo, which in turns, builds the charge side (boost pressure) of the turbo. If the boost pressure is too high, then the spring begins to open up a valve and the excessive exhaust pressure is released, or vented out and doesn't make it to the charge side of the turbo. In that way the boost pressure is limited. As the boost pressure falls, the valve begins to close and diverts exhaust gas pressure back into the turbo.

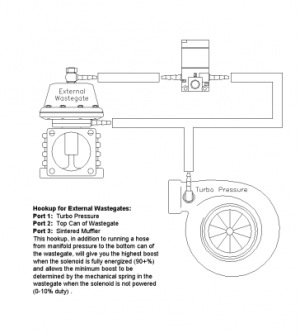

In the top chamber of the wastegate you have a reference port and a controller port. From the diagram you can see that the relationship between the two pressures is key to controlling how much exhaust pressure actually enters your turbo. Now, if the reference port is piped to the turbo outlet and the control port is capped, then the wastegate reference port will see the turbo boost pressure only. So in theory, when the turbo outlet pressure matches the spring pressure, it will begin to lift/open the exhaust plunger and release the excessive exhaust gas pressure, bypassing the charge side of the turbo. In this way, you can control the boost pressure to what the actual spring pressure is. So if you have an exhaust pressure of 5 psi, then the reference port will be 5 psi. If you had a 7 psi spring, then there would not be enough pressure to open the spring and it would send all of the exhaust pressure (5 lbs) to the charge side of the turbo. However, if the exhaust pressure was 12 psi, then the reference port would see 12 psi. Since the spring would still be at 7 psi, then (12 > 7) the spring would start to open at 7 psi and control/limit the amount of exhaust pressure the turbo sees and would hold the boost pressure to 7 psi. *In theory of course. The reality is that the spring will start to leak a bit before 7 psi.

So where does the controller port come into play? Let's say we want something other than 7 psi. A boost controller can alter the differential pressure between the reference port and the controller port by limiting or controlling the amount of pressure that the controller port sees, relative to the reference port. Let's say we have a solenoid piped in like the diagram above. If it is nominally closed (unpowered closed) then it would act like a capped controller port in the example above. The wastegate should operate on spring pressure alone. However, if I start to open the solenoid, I can push some pressure on the controller port side of the wastegate. In essence this helps build additional pressure on the spring side so that the reference port would have to build up more pressure on the spring to release the valve/plunger to release the exhaust gas pressures.

So if we have 12 psi of exhaust pressure, by opening up the normally closed solenoid, the control port can see, say 2 psi. That means the spring side of the wastegate would require 9 lbs of reference port pressure (7 psi from the spring + 2 additional psi from the turbo boost pressure). The boost pressure would rise and control to 9 psi before releasing exhaust pressure. This relationship is important because you can see that the additional pressure the wastegate can hold using an electronic boost controller is dependent on this differential pressure. If something was restricting the pressure on any part of the piping, you could false pressures on your wastegate. This is going to be much more prevalent if you have an open feedback loop on your boost controller, becasue there would be no way for it to know and adjust. The same thing could potentially happen if the pressures are not equalized, so that say the flow is restricted somehow (due to diameter changes, extra tubing length, restrictions, etc.) so that the same 12 psi of boost pressure is not hitting the reference side port or solenoid at the same equal 12 psi. It's important to note that a change in diameters is not necessarily a good thing. Pressure is a function of flow and area (in this case cross sectional diameter). If you increase the diameter then you will decrease pressure. If you have different diameter connections between each of your components, as mentioned above, then each component will see a different pressure. If they are each seeing a different pressure, then it could help explain the boost creep problem you are experiencing. Now, your turbo side barb size isn't as critical because it will just be your baseline pressure, but all the other barb fittings downstream of that (wastegate, solenoid) need to be exactly the same diameter and tube diameter.

So now that I've had a chance to think about it some more, here's what I would try:

1) First and foremost, make sure all of the barb fittings and tube diameters are the same downstream of the turbo barb. Everything should be consistent from the wastegate, to the solenoid all the way back to the turbo, including the T fittings. You shouldn't technically have to change the turbo fitting. Although I've seen weirder things happen.

2) Next keep the boost controller solenoid in place, but disconnect the tubing to the wastegate on the control barb. Leave it open so it gives a zero pressure input. In theory you should be running on spring pressure only.

3) On the loose tubing from the solenoid, put a snug but not tight plug to cap that side and disable control of the solenoid.

4) Run on spring pressure and see if you get any boost creep in this configuration. You shouldn't so it will be very telling if you do. Check the loose tubing from the solenoid and snug cap on the tubing. If it is still in place then your solenoid is good. However, if the plug has shot off, it means your solenoid somewhere is leaking pressure by and that is no good.

5) Next reconnect your solenoid control but do not connect it to the wastegate control port yet. If you have any means to measure the pressure on that tube that would be great. If not, put the snug plug on that side and try running again. This time you can verify that the solenoid is opening and should shoot the plug off.

6) Finally reconnect the boost controller solenoid to the control port of the wastegate and test again.

7) If you are getting boost creep at this point, we might have to look at your boost controller programming. You'll have to verify if it is an open loop or closed loop control and then we can go from there.

Sorry for the convoluted mess but it's hard to type out; much easier if I was there just looking at it. But hopefully you got something useful out of this and maybe help solve the issue. :smile: