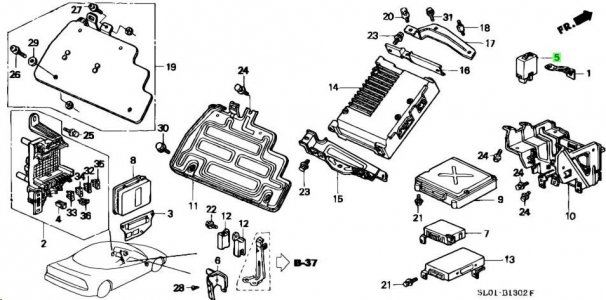

It's on the R-side (driver side for the RHD).

Probably missed the tiny square on the right in the parts diagram.

Remove the lower cover under the steering column.

2 x screw (blue).

Be careful not to lose the 2 x rubber cap (red).

Disconnect 1 x blue connector from the foot well light.

You can just about see the brown connector with custard sleeve for the flasher relay (yellow).

Remove 1 x fastener (blue) to peel off the carpet for better access.

The brown connector with the black square case.

If someone worked in the area in the past, could be tacked away somewhere else.

Move the car to quiet area.

Avoid other noise so don't run the engine.

Don't insert the IG key into IGSW cyl if you have the key reminder feature.

Activate the hazard lights and crawl into the driver foot well.

Listen for the clicking sound of the mechanical relay.

Once found the black case, try placing your finger on it.

You can actually feel the 'clicking'.

Never tried separating the relay from the bracket without removing extra parts.

You could remove the side cowl that runs along the side sill/carpet.

It includes the plastic trim around the bonnet opener.

When the temperature is low, easily break the plastic parts on classic cars so be careful.

I normally warm up the cabin when working on plastic trim during the winter time.

The majority of black relay housing/case is hidden/behind the a/c duct and the top section is locked with a horizontal bracket so not easy to take the relay out of the cabin.

With LHD model that has L-shaped bracket with lock at the top of relay, seems like you can use the 'twist' trick to apply enough leverage to unlock the bracket.

With RHD, the bracket is more of horizontal shape that don't know the same trick can be used.

Never tried the following so don't count on this.....

After disconnecting the connector to prevent the short circuit, may be you can run flat blade driver along the yellow dotted section to pry out the circuit board???

If same structure as the Main Relay, it should come out together with the bottom connector housing.

This will leave the bracket and the black housing as they are.

Again, never tried before so don't know it's possible or not.

Kaz

![IMG_6323[1].JPG](/data/attachments/125/125618-c8dd30e2a5cf4a5811a4530c3d5afb3a.jpg)