- Joined

- 1 October 2018

- Messages

- 9

Hi all,

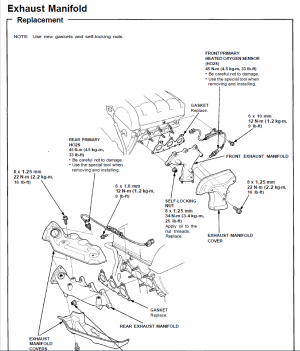

Does anyone have paperwork/diagrams for a comptech header?

I purchased a 95 last November and one of the previous owners had installed a comptech header and exhaust system. The car has been stumbling at low rpm's (feels like a large loss of power, I don't really push it into the higher end >4k, its just a mental thing. Recent purchase so I'm afraid of punching it when it's not working so great) so I've been going through the usual check list, I've:

-Cleaned throttle body (this fixed RPM's dying to 300 when I came to a stop)

-Replaced Spark plugs, I'm in Jersey and I am using it as a daily when the weathers above 60. Water has gotten into the rear bank and I've purchased some rubber strips that I plan on diverting the water to the sides with. I took out the coils the other weekend but didn't see anything wrong with them. I hit them with some compressed air and then some of that quick dry electronics cleaner. I popped them back in and went for a 30 minute drive and the car drove like it never did before. Threw my head back into the chair during acceleration.

- Now I'm chasing that high and from what I've read the o2 sensors are next. I did the recommended unplug the connectors on top and take it for a spin, it was smoother but the acceleration still wasn't anywhere near as that perfect day was.

- After I do o2 ill probably just splurge and get the new coil packs if needed.

Anyways back to my original point. I can access the pigtail connectors from the engine bay on top quite easily. I have no idea where the other ends, the actual o2 sensors, are going. I'm guessing it's something I'll have to do from underneath but any information would be helpful rather than going in blind.

Does anyone have paperwork/diagrams for a comptech header?

I purchased a 95 last November and one of the previous owners had installed a comptech header and exhaust system. The car has been stumbling at low rpm's (feels like a large loss of power, I don't really push it into the higher end >4k, its just a mental thing. Recent purchase so I'm afraid of punching it when it's not working so great) so I've been going through the usual check list, I've:

-Cleaned throttle body (this fixed RPM's dying to 300 when I came to a stop)

-Replaced Spark plugs, I'm in Jersey and I am using it as a daily when the weathers above 60. Water has gotten into the rear bank and I've purchased some rubber strips that I plan on diverting the water to the sides with. I took out the coils the other weekend but didn't see anything wrong with them. I hit them with some compressed air and then some of that quick dry electronics cleaner. I popped them back in and went for a 30 minute drive and the car drove like it never did before. Threw my head back into the chair during acceleration.

- Now I'm chasing that high and from what I've read the o2 sensors are next. I did the recommended unplug the connectors on top and take it for a spin, it was smoother but the acceleration still wasn't anywhere near as that perfect day was.

- After I do o2 ill probably just splurge and get the new coil packs if needed.

Anyways back to my original point. I can access the pigtail connectors from the engine bay on top quite easily. I have no idea where the other ends, the actual o2 sensors, are going. I'm guessing it's something I'll have to do from underneath but any information would be helpful rather than going in blind.