The other day I was tracking my -91 and when accelerating out of a left corner the rear right knuckle cracked where the toe link (control arm) is bolted, the toe link was completely lose from the knuckle.

This resulted in me fish tailing all over the place, I managed to stay on the track though and saved the rest of the car. :smile:

I have only found a thread by titaniumdave about this so I don't know if this really is an issue or just some previous mechanic that used som brute force on the part when changing ball joint or something leaving it with a small crack perhaps?

http://www.nsxprime.com/forum/showt...the-track!-!Rear-knuckle-cracked-rear-knuckle!!

So any suggestion about future tracking, just replace the knuckle (hub carrier) with a used one and go on with it?

Or should I get a brand new one to be sure its not faulty already?

Anything else that can make this happen, bad alignment, car to low, to stif or just to many visits on the curbs?

Any info will be appreciated :smile:

/Patrik

I managed to drive home after fixing it with steel wire and a hose clamp.

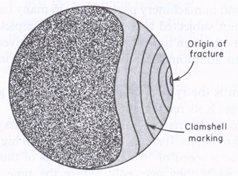

You can spot the crack inside the ellips.

This resulted in me fish tailing all over the place, I managed to stay on the track though and saved the rest of the car. :smile:

I have only found a thread by titaniumdave about this so I don't know if this really is an issue or just some previous mechanic that used som brute force on the part when changing ball joint or something leaving it with a small crack perhaps?

http://www.nsxprime.com/forum/showt...the-track!-!Rear-knuckle-cracked-rear-knuckle!!

So any suggestion about future tracking, just replace the knuckle (hub carrier) with a used one and go on with it?

Or should I get a brand new one to be sure its not faulty already?

Anything else that can make this happen, bad alignment, car to low, to stif or just to many visits on the curbs?

Any info will be appreciated :smile:

/Patrik

I managed to drive home after fixing it with steel wire and a hose clamp.

You can spot the crack inside the ellips.