Seeing as this car has come a long way since I originally got it back in November 2019, I figured it’s about time I actually document the parts and work I have done over the years to get this car closer and closer to perfect for me. Surprisingly, I didn’t initially have any grand plans for what I wanted to do with it, but the car really grew on me the more and more I drove it and in some ways I may have gone off the deep end modding it…

When I first bought the car it was stock except for a K&N cone type intake that sat in the engine bay, the HRE wheels, Bilstein shocks with Tein lowering springs and some pretty jank installed head unit and door speakers.

“Pretty good looking car” was the first thing I thought when I laid eyes on it, and the opportunity to buy it kind of fell into my lap so I went for it. At first driving it was nothing special to me but the more and more I did drive it the more it grew on me, but that turned into a couple of things I wanted to address.

First thing I ended up doing was an exhaust(of course….). Got a used Ark cat back from a for sale thread on here, bought the cheapest headers and test pipes I found online and slapped it all on. Needless to say, being that the headers were bottom dollar they needed to be lightly “massaged” to get them to clear the oil pan

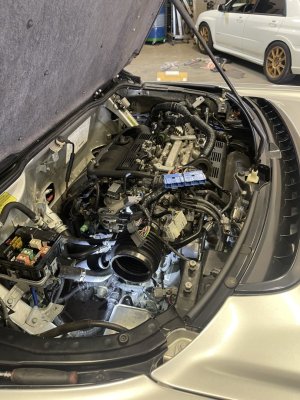

Anyway….with that problem out of the way, the car was back together and sounded great, after being on the stock exhaust for 8 months it was 1000x better sounding. After this the next main concern was getting the maintenance up to date, who knew when the last timing belt service was done, the original radiator looked like it had seen better years, and the engine had some valve cover gasket/oil pan gasket seepage. I had been dreading doing the job because the car did not look like it was fun to work on at all with the engine in the car, so one day I just sucked it up and brought the car into the shop on a weekend and dropped the motor out of it, since that seemed like the less painful solution.

Surprisingly dropping the motor out is relatively painless on these cars and it was out in less time than I was initially thinking it was gonna take.

Taking the timing stuff apart is way way easier this way than to try and fight with it in the car 2 inches away from the frame rails.

New belt, tensioner, water pump, cam and crank seals, valve cover gaskets, and oil pan gasket, and did a Koyo rad to replace the stock one.

After all that it went right back in and the car was running same day. I had noticed when it was all apart that the cam/crank sensor had puked out all its epoxy guts down the side of the engine, but looking it up on here it seems like that’s common and doesn’t affect the sensor operation for the most part. But being how I am, once I saw something that could be an issue it bothered me, enough that I looked it up in the service manual and checking the sensor resistance, it being out of spec was enough justification for me to buy a new sensor and drop the motor out again to swap it. (I got problems…)

Thankfully, the first time is always the hardest and this time I had the motor out, sensor swapped, and motor back in running starting at about 4pm and driving home at about 11:30pm which wasn’t half bad. After I had the peace of mind of having this addressed the next concern was getting the radio catastrophe fixed and I wanted to swap over to an S2k dash because I always loved how it looks and it really doesn’t look out of place in this car in my opinion. Thankfully that process was easy because of the great plug and play kit that Sjoeberg sells.

Painless install, looks great, win win. The radio and door speakers on the other hand…..yikes. At this point I basically never turned the radio on because half the time if I hit a bump it would stop working, and it was just such an eyesore.

The dash was just chopped up and the head unit plopped in, the door panels were also mangled because whoever did the install clearly had no idea how to take them off so they just broke them and used screws to hold it together with hopes and dreams.

Just all around A1 quality work here….Mita motorsports door kit, and SoS speaker install panels and Mita tweeter pods fixed this whole situation up with the doors.

Had to lightly modify these to fit my larger morel tweeters but the end result came out looking really good..

When I first bought the car it was stock except for a K&N cone type intake that sat in the engine bay, the HRE wheels, Bilstein shocks with Tein lowering springs and some pretty jank installed head unit and door speakers.

“Pretty good looking car” was the first thing I thought when I laid eyes on it, and the opportunity to buy it kind of fell into my lap so I went for it. At first driving it was nothing special to me but the more and more I did drive it the more it grew on me, but that turned into a couple of things I wanted to address.

First thing I ended up doing was an exhaust(of course….). Got a used Ark cat back from a for sale thread on here, bought the cheapest headers and test pipes I found online and slapped it all on. Needless to say, being that the headers were bottom dollar they needed to be lightly “massaged” to get them to clear the oil pan

Anyway….with that problem out of the way, the car was back together and sounded great, after being on the stock exhaust for 8 months it was 1000x better sounding. After this the next main concern was getting the maintenance up to date, who knew when the last timing belt service was done, the original radiator looked like it had seen better years, and the engine had some valve cover gasket/oil pan gasket seepage. I had been dreading doing the job because the car did not look like it was fun to work on at all with the engine in the car, so one day I just sucked it up and brought the car into the shop on a weekend and dropped the motor out of it, since that seemed like the less painful solution.

Surprisingly dropping the motor out is relatively painless on these cars and it was out in less time than I was initially thinking it was gonna take.

Taking the timing stuff apart is way way easier this way than to try and fight with it in the car 2 inches away from the frame rails.

New belt, tensioner, water pump, cam and crank seals, valve cover gaskets, and oil pan gasket, and did a Koyo rad to replace the stock one.

After all that it went right back in and the car was running same day. I had noticed when it was all apart that the cam/crank sensor had puked out all its epoxy guts down the side of the engine, but looking it up on here it seems like that’s common and doesn’t affect the sensor operation for the most part. But being how I am, once I saw something that could be an issue it bothered me, enough that I looked it up in the service manual and checking the sensor resistance, it being out of spec was enough justification for me to buy a new sensor and drop the motor out again to swap it. (I got problems…)

Thankfully, the first time is always the hardest and this time I had the motor out, sensor swapped, and motor back in running starting at about 4pm and driving home at about 11:30pm which wasn’t half bad. After I had the peace of mind of having this addressed the next concern was getting the radio catastrophe fixed and I wanted to swap over to an S2k dash because I always loved how it looks and it really doesn’t look out of place in this car in my opinion. Thankfully that process was easy because of the great plug and play kit that Sjoeberg sells.

Painless install, looks great, win win. The radio and door speakers on the other hand…..yikes. At this point I basically never turned the radio on because half the time if I hit a bump it would stop working, and it was just such an eyesore.

The dash was just chopped up and the head unit plopped in, the door panels were also mangled because whoever did the install clearly had no idea how to take them off so they just broke them and used screws to hold it together with hopes and dreams.

Just all around A1 quality work here….Mita motorsports door kit, and SoS speaker install panels and Mita tweeter pods fixed this whole situation up with the doors.

Had to lightly modify these to fit my larger morel tweeters but the end result came out looking really good..