I had a spare intake manifold assembly laying around, so I thought I'd perform a complete "servicing" of the VVIS plate.

Here's the VVIS plate in "as is" form.

Here's the #2 plate (middle) upclose. Notice the gunk? This is off a car with about 54,000 miles.

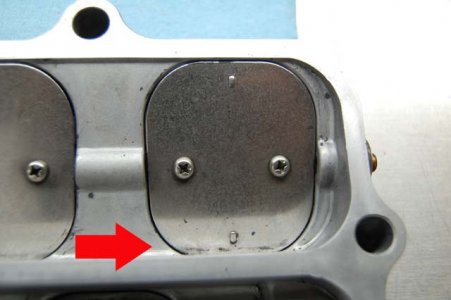

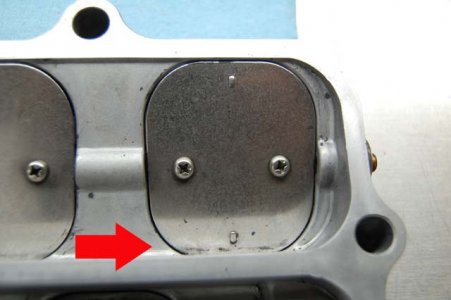

Here's the #3 plate. Lots of gunk (arrow) there.

I simply took a small flathead screwdriver and simply chipped (or "chunked") away the gunk. Here are the "leftovers" after a cursory chunking session.

Here is the #3 plate after cleaning (looks better, doesn't it?):

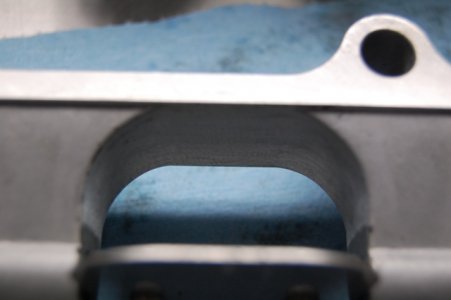

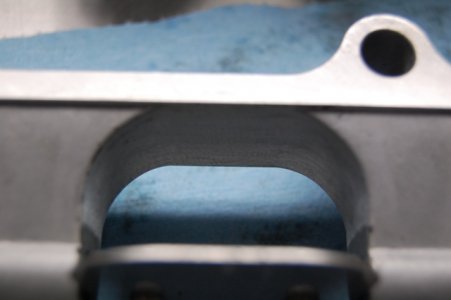

Now, I want to remove to the "ridges" that were leftover from (I'm assuming) the casting process. I'm not an engineering, but I'm assuming that those aren't good in the airflow-scheme of things:

Using my Makita die grinder and a 180-grit cartridge roll, I cleaned everything up. The results:

(Smooth like a baby's butt).

Finally, I went ahead I applied Loctite Red (271) threadlocker to all my VVIS screws. In my case, I did NOT find any that were loose. Your results may vary.

Here's the VVIS plate in "as is" form.

Here's the #2 plate (middle) upclose. Notice the gunk? This is off a car with about 54,000 miles.

Here's the #3 plate. Lots of gunk (arrow) there.

I simply took a small flathead screwdriver and simply chipped (or "chunked") away the gunk. Here are the "leftovers" after a cursory chunking session.

Here is the #3 plate after cleaning (looks better, doesn't it?):

Now, I want to remove to the "ridges" that were leftover from (I'm assuming) the casting process. I'm not an engineering, but I'm assuming that those aren't good in the airflow-scheme of things:

Using my Makita die grinder and a 180-grit cartridge roll, I cleaned everything up. The results:

(Smooth like a baby's butt).

Finally, I went ahead I applied Loctite Red (271) threadlocker to all my VVIS screws. In my case, I did NOT find any that were loose. Your results may vary.

Last edited: