I'm having my motor rebuilt and while it's apart, I'm considering having the DC headers and new Weisco pistons ceramic coated.

Here are my specs:

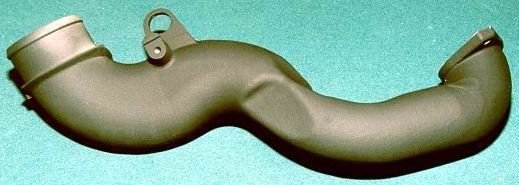

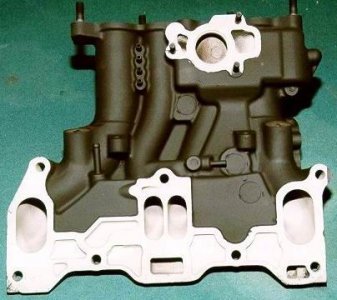

DC Headers with 10K miles.

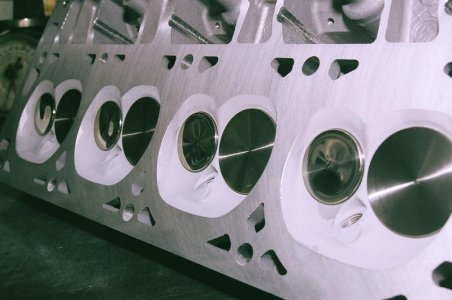

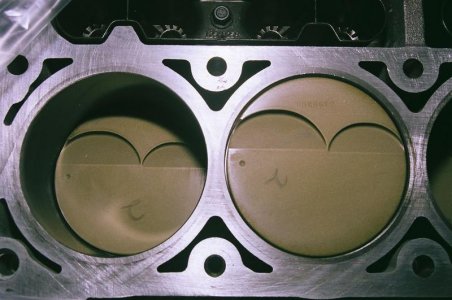

1994 motor with new Darton Sleeves and new 93mm Weisco pistons = 3.2 litres.

9.5:1 compression.

Twin HKS 2510 turbos, water-cooled, ball bearing.

Air to water intercooler.

Water/Methanol injection.

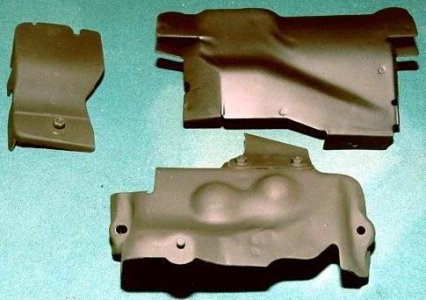

(numerous other goodies)

I'd like to hear of any experiences and opinions regarding the benefits or drawbacks with ceramic coating the headers and pistons... and any recommended coatings or shops to do the work. My car is in San Diego.

If I'm going to ceramic coat the headers and/or pistons now is the time for me to have it done.

I'm getting the NSX ready for the 10,000 mile trip to and from NSXPO.

Any comments will be GREATLY APPRECIATED!

Here are my specs:

DC Headers with 10K miles.

1994 motor with new Darton Sleeves and new 93mm Weisco pistons = 3.2 litres.

9.5:1 compression.

Twin HKS 2510 turbos, water-cooled, ball bearing.

Air to water intercooler.

Water/Methanol injection.

(numerous other goodies)

I'd like to hear of any experiences and opinions regarding the benefits or drawbacks with ceramic coating the headers and pistons... and any recommended coatings or shops to do the work. My car is in San Diego.

If I'm going to ceramic coat the headers and/or pistons now is the time for me to have it done.

I'm getting the NSX ready for the 10,000 mile trip to and from NSXPO.

Any comments will be GREATLY APPRECIATED!

Last edited: