Engine Refresh 1

With 317 waiting patiently for her replacement door, I decided to turn to the engine. It will be getting a full refresh will all new parts, timing belt, water pump and seals. The heads are getting Comptech cams and all new valvetrain from Science of Speed, along with a 3-angle valve job and general cleanup.

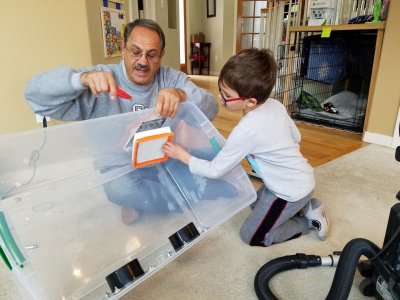

To start, we used the hoist to remove the engine and transmission from the rear subframe. You can see that is was easier to work with the front beam completely removed. Also, because of the size of the auto transmission, we had to remove the left side beam assembly to hoist it out.

Powertrain removed.

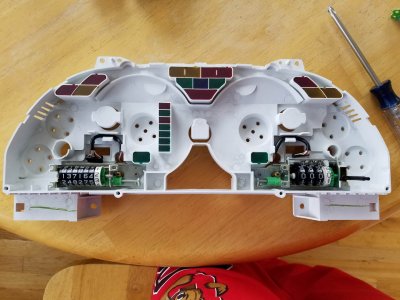

Next was to remove the auto transmission. This....took some effort. That thing looks small, but it has to weigh at least 100 pounds! It is a BEAST and I recommend just using a hoist to move it around. Spencer and I are pretty strong guys, and we struggled.

Hoisting the engine was the next step to get it ready to go on the engine stand for disassembly. The engine only has one hoist point, so we put one of the transmission bolts in the block to give it a second lift point. We ended up using a shorter bolt then the one pictured here in order to get the lift point closer to the block.

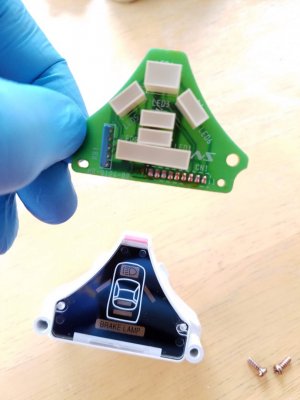

Since it was so easily accessible, I blasted the crank pulley bolt off with the Big Beast. One squeeze of the trigger and it was gone. After watching so many Prime members struggle with 6ft cheater bars and such over the years, it was a welcome relief.

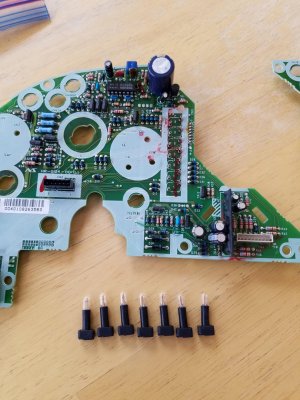

What was NOT a relief was the engine stand. Being a good attorney, I came prepared. Weeks ago, I went to ACE Hardware and grabbed four 70mm M12 bolts with a 1.25 "JIS" thread pitch. Once we got the engine lined up with the stand, I started the bolts and they stopped dead after about 2 turns. Steel vs. aluminum so I backed them out gently and tried a different bolt- maybe the threads on the first one were damaged? Nope, same thing- two turns and then STOP. I grabbed one of the Honda trans bolts and tried it- threaded in like butter. With the engine dangling in the air 2 feet off the ground- we had no choice- my C30A is being held onto the engine stand with 3 OEM bolts (one sleeved through the lower right hole on the block) and one mount arm flopping loose. I'd really like to rectify this sooner vs. later. Can anyone who has mounted the C30A to an engine stand help? What bolts should i use???