-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Honcho's Long Road to Imola Type-S Zero

- Thread starter Honcho

- Start date

Hey.. HE SAID IT, not me :biggrin:I think Jerry was making sexy time with heads......

Re-Assembly 38

Passenger Door Weather Strip, Membrane, etc.

Spent the day fitting the door rubbers, carbon fiber B-pillar and restored upper trim.

For the membrane, I made a mistake and ordered the JDM versions, which are for the RHD cars. We had to get a little creative with some clear tape, but we were able to use them effectively. Special thanks to [MENTION=33247]MotorMouth93[/MENTION], who pointed me to the correct butyl tape for adhering the membrane and the tip to fit the door handles (and anything else that screws into the door first before sticking the membrane to the adhesive. It ensured we had enough material to go all the way around.

Small modification Spencer made to accommodate the door handle cable. Clear tape will hopefully prevent the future tearing.

The S Zero life. No speakers on this NSX. I don't like how it bubbles out, so I may just screw in the membrane to the speaker holes to hold it more flush to the door. You can see some water drops from the water test for the door rubber. Membrane doing its job.

Key point on the door rubbers that is NOT addressed in the manual- you must remove the door check pin from the hinge to fit the outer strip. This requires it to be knocked out (from the bottom) with a hammer and punch. 5 minutes of sheer terror considering the brand new paint. Also, you have to lift the outer window trim piece to fit one of the rubber press pins (it goes into the front sash on the outside).

Fitting the body upper rubber. You must tuck the small lip of the rubber into the slot inside the trim piece. Then, tuck the bottom lip. Many people miss this step and get leaks/wind noise. Start at the black window stop to center the piece and work outwards in each direction. If it is done properly, it should look like this:

You can see the faint line from the window glass here in the rubber. A good sign, though a bit more window adjustment was needed.

Overall, I was very pleased with the fitment of the Mita Motorsports carbon B-Pillars. @MITA Motorsports did a nice job with these pieces at a reasonable price.

This seam required some filing of the B-pillar to get it to fit properly. The price of wanting to go fast.

Somehow all of the body panels lined up perfectly.

Passenger Door Weather Strip, Membrane, etc.

Spent the day fitting the door rubbers, carbon fiber B-pillar and restored upper trim.

For the membrane, I made a mistake and ordered the JDM versions, which are for the RHD cars. We had to get a little creative with some clear tape, but we were able to use them effectively. Special thanks to [MENTION=33247]MotorMouth93[/MENTION], who pointed me to the correct butyl tape for adhering the membrane and the tip to fit the door handles (and anything else that screws into the door first before sticking the membrane to the adhesive. It ensured we had enough material to go all the way around.

Small modification Spencer made to accommodate the door handle cable. Clear tape will hopefully prevent the future tearing.

The S Zero life. No speakers on this NSX. I don't like how it bubbles out, so I may just screw in the membrane to the speaker holes to hold it more flush to the door. You can see some water drops from the water test for the door rubber. Membrane doing its job.

Key point on the door rubbers that is NOT addressed in the manual- you must remove the door check pin from the hinge to fit the outer strip. This requires it to be knocked out (from the bottom) with a hammer and punch. 5 minutes of sheer terror considering the brand new paint. Also, you have to lift the outer window trim piece to fit one of the rubber press pins (it goes into the front sash on the outside).

Fitting the body upper rubber. You must tuck the small lip of the rubber into the slot inside the trim piece. Then, tuck the bottom lip. Many people miss this step and get leaks/wind noise. Start at the black window stop to center the piece and work outwards in each direction. If it is done properly, it should look like this:

You can see the faint line from the window glass here in the rubber. A good sign, though a bit more window adjustment was needed.

Overall, I was very pleased with the fitment of the Mita Motorsports carbon B-Pillars. @MITA Motorsports did a nice job with these pieces at a reasonable price.

This seam required some filing of the B-pillar to get it to fit properly. The price of wanting to go fast.

Somehow all of the body panels lined up perfectly.

Attachments

Re-Assembly 39

Window Seal Water Test and Side Skirt

Checking the final window alignment. The glass is pushed out a few mm due to the new rubber. The window required 1/2 turn more of inside movement on the glass adjusters to create a solid seal on the rubber. Once we were satisfied, we did the water test. Spencer sat inside the car and I dumped water all over the seam. Success. No leaks.

Now to set the rubber. Raise the glass and then close the door. Need to do this for a while so the rubber takes a set. You should not close the window into the new rubber as it could tear or damage the material.

The side skirt was fairly simple. It took a minute to figure out how to set the new rubber seals. But, everything snapped into place correctly.

Very pleased with the fitment. This side of the car is done. Driver side next.

Window Seal Water Test and Side Skirt

Checking the final window alignment. The glass is pushed out a few mm due to the new rubber. The window required 1/2 turn more of inside movement on the glass adjusters to create a solid seal on the rubber. Once we were satisfied, we did the water test. Spencer sat inside the car and I dumped water all over the seam. Success. No leaks.

Now to set the rubber. Raise the glass and then close the door. Need to do this for a while so the rubber takes a set. You should not close the window into the new rubber as it could tear or damage the material.

The side skirt was fairly simple. It took a minute to figure out how to set the new rubber seals. But, everything snapped into place correctly.

Very pleased with the fitment. This side of the car is done. Driver side next.

Lookin' good!

Thanks for all the tips on the door seals. I was wondering how to fit the lower door seals and thought you had to remove the whole stupid door to fit the seal around the hinge. Hopefully once I finally get to adjusting my windows the upper seals aren't set in a bad spot. I'm sure that was a fun experience for you.

Thanks for all the tips on the door seals. I was wondering how to fit the lower door seals and thought you had to remove the whole stupid door to fit the seal around the hinge. Hopefully once I finally get to adjusting my windows the upper seals aren't set in a bad spot. I'm sure that was a fun experience for you.

Lookin' good!

Thanks for all the tips on the door seals. I was wondering how to fit the lower door seals and thought you had to remove the whole stupid door to fit the seal around the hinge. Hopefully once I finally get to adjusting my windows the upper seals aren't set in a bad spot. I'm sure that was a fun experience for you.

Don't forget the other tip he mentioned...the front of the lower seal actually clips into the OUTSIDE of the front sash. We originally clipped it into the wrong spot before we realized where it went. So that meant we had to take off the front sash plate, undo the outer moulding screw and then pop the outer moulding off the door. Then because the leverage sucks we couldn't get the pin pushed in all the way and had to tap it in with a hammer.

Door membranes: if you remove the speakers and fit a thin plastic membrane in the hole, a cheap noise can result whenever you close the door. Don't ask me how I know.I had to fill the hole in the door with a thicker medium used for sound deafening.

Thankfully (or maybe luckily) I don't have any noises when I shut the door- other than the very satisfying thunk of a well-aligned NSX door closing on fresh seals.

So since you are now a self taught window ninja what is my diagnosis. My passenger window goes up and down fully but intermittently makes a cracking sound only going up...speed is similar to driver side that is silent.

Most likely cause is the window carrier (the bracket that bolts to the glass itself) is not greased. It slides horizontally along a plastic cylinder as it goes up and down and will make popping or cracking sounds if it gets dry. Kinda tricky to grease it without taking out the regulator, but you might be able to reach it. I'll check my driver door tonight.

So since you are now a self taught window ninja what is my diagnosis. My passenger window goes up and down fully but intermittently makes a cracking sound only going up...speed is similar to driver side that is silent.

Here is a link to to the TSB covering the sticky spool in the window regulator mechanism

TSB 93-004 - NSX-Wiki (nsxprime.com)

Not easy; but, you can grease it with the regulator still in the door. I did - after I reinstalled the regulator following the Hugo kit installation and forgot to re grease the spool after I had cleaned everything up. I think I used a cotton swab held by some long needle nose pliers to get at the spindle that the spool slides back and forth on.

Last edited:

Re-Assembly 40

Driver door seals, membrane, door jamb stickers

Spencer's car is here for its B82 blue Type-S conversion and clutch service. That means my car is getting close to the end. We will begin stripping body panels shortly.

Back to the S Zero. The door seals are fitted and the door check pin installed. I still managed to nick the paint with the hammer despite taping the area for protection. Not a huge worry, as the car must still go back to the body shop for final buffing and touchups. There are a few nicks and chips from re-assembly.

[HOLD]

One major issue we discovered after aligning the window glass. The old accident popped off the panel stiffener from the body adhesive inside the door. When the window is adjusted close to the body, the glass trolley strikes the beam as it moves by. Adjust too far and it actually gets stuck. What to do? My temporary solution is to adjust the glass as close as possible while still permitting window movement. Thankfully, we appear to have a good seal at the window rubber. Also, as a precaution, I greased the beam where the trolley contacts it to help it get over the bump, which helped immensely. Bottom line, the window only goes down freely about halfway and I will only lower it fully if absolutely necessary. A longer-term solution will be to take it to my body shop and likely will involve a giant C-clamp and new panel adhesive to glue the stiffener back to the panel. Or, I may just cut a notch in the beam to permit the trolley to travel past without contact- this beam is not part of the crash protection. Instead, its purpose is to prevent the outer aluminum skin from deforming if bumped (think shopping cart or parking lot bump). Welcome to classic car life.

The door jamb stickers were a matter of some debate. Since the concept of this car is that it was a special order from Japan (a US S Zero trim spec), I decided to use the Zanardi sticker in the driver's side and the S Zero sticker on the passenger side. The car would have to have the Zanardi sticker to be road-legal here, but Tochigi likely would have also put the S Zero sticker in the traditional location. My crazy reasoning anyway.

The Zanardi sticker.

S Zero (J51)

Driver door seals, membrane, door jamb stickers

Spencer's car is here for its B82 blue Type-S conversion and clutch service. That means my car is getting close to the end. We will begin stripping body panels shortly.

Back to the S Zero. The door seals are fitted and the door check pin installed. I still managed to nick the paint with the hammer despite taping the area for protection. Not a huge worry, as the car must still go back to the body shop for final buffing and touchups. There are a few nicks and chips from re-assembly.

[HOLD]

One major issue we discovered after aligning the window glass. The old accident popped off the panel stiffener from the body adhesive inside the door. When the window is adjusted close to the body, the glass trolley strikes the beam as it moves by. Adjust too far and it actually gets stuck. What to do? My temporary solution is to adjust the glass as close as possible while still permitting window movement. Thankfully, we appear to have a good seal at the window rubber. Also, as a precaution, I greased the beam where the trolley contacts it to help it get over the bump, which helped immensely. Bottom line, the window only goes down freely about halfway and I will only lower it fully if absolutely necessary. A longer-term solution will be to take it to my body shop and likely will involve a giant C-clamp and new panel adhesive to glue the stiffener back to the panel. Or, I may just cut a notch in the beam to permit the trolley to travel past without contact- this beam is not part of the crash protection. Instead, its purpose is to prevent the outer aluminum skin from deforming if bumped (think shopping cart or parking lot bump). Welcome to classic car life.

The door jamb stickers were a matter of some debate. Since the concept of this car is that it was a special order from Japan (a US S Zero trim spec), I decided to use the Zanardi sticker in the driver's side and the S Zero sticker on the passenger side. The car would have to have the Zanardi sticker to be road-legal here, but Tochigi likely would have also put the S Zero sticker in the traditional location. My crazy reasoning anyway.

The Zanardi sticker.

S Zero (J51)

Last edited:

.so with a month gap in updates I'm assuming you are having engine build issues beyond your control...

Blame this.

It has had two effects: (1) I've had to become an RV mechanic the last 2 months; and (2) we're gone most every weekend (where I would normally be working on the NSX)- this photo is from our first test camp at Boyd Lake. We were up at Turquoise Lake near Mt. Elbert this weekend. Basically, all of my free time has been spent repairing/preparing the RV. One thing I've learned from being a husband and father is that you need to let go of your personal stake in your hobbies. Once you have kids, it's not about you anymore. This was a tough struggle for me, especially early on. Now, with time and perspective, I'm come to grips with it. Watching my family play and laugh is so much more rewarding, and I will always choose them over the car. The car will be done when it's done, and I'm ok with that. That said, I've got a month before our next trip (a 7-day adventure across the West), so expect some updates soon.

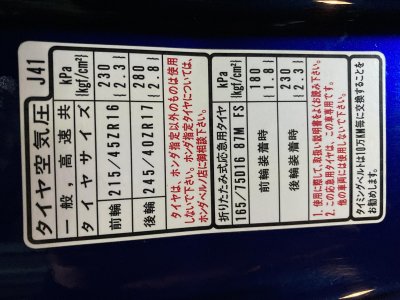

Cool, right? Also, it seems the R and S Zero have a different part number for the OEM 16/17 tires.Hi Honcho,

Just had a close look at the two tire stickers posted above and noticed the different pressures. FYI, here is the sticker from my Type S

View attachment 169948Only sllightly different to your two! - just shows that there are small variations between the variants.

Last edited:

.so with a month gap in updates I'm assuming you are having engine build issues beyond your control...

Hey, I resemble that...

COVID19 seems to have caused a lot of engine build issues. Takes forever to get anything manufactured or machined right now.

Cool, right? Also, it seems the R and S Zero have a different part number for the OEM 16/17 tires.

Yes - I noticed that as well.

J11 = Yokohama for Type R 15/16

J12 = Bridgestone for Type R 15/16

A12 = Bridgestone for S-Zero 16/17

A22 = Bridgestone Twin Tyre (TT-01) for S-Zero 16/17

J21 = Yokohama for S-Zero 16/17

J31 = Yokohama for S-Zero & Type R 16/17

J32 = Bridgestone for S-Zero & Type R 16/17

R01 = Bridgestone for 02+ Type R 17/17

There are even more codes for different brands (eg Dunlop) for different years of production across the other the other variants ("regular" NSX, Type S, Type T, Automatic etc. etc.)

Brake Overhaul 07

Front Calipers

Re-assembling the front calipers. Although I purchased a full set of new pistons from Honda, the original pistons were in remarkably good shape and can be re-used.

When the square seal is properly installed, you should be able to easily push the piston in.

Using my trusty Dow Corning DC-4 silicone grease. I have had very good luck with this grease on my last NSX, where the brakes were used in winter snow, ice and sand conditions as well as at the racing circuit in 100F temperatures. I put a light coat on the piston surface and coat the square seal. It makes inserting the pistons quite easy. I also put a coat on the dust boot to aid in keeping water out of the piston cavity.

The "wrong" way. There is really no good way to get the dust boot lip into the groove on the caliper in this orientation.

The "right" way. It takes two people, but if one person stretches the opening and the other inserts the piston, it works quite well.

Note- these are the Centric branded dust boots. I recall that [MENTION=35590]Big McLargeHuge[/MENTION] was having fitment issues with his, but these fit perfectly. I wonder if they sent him the wrong ones by accident?

Front Calipers

Re-assembling the front calipers. Although I purchased a full set of new pistons from Honda, the original pistons were in remarkably good shape and can be re-used.

When the square seal is properly installed, you should be able to easily push the piston in.

Using my trusty Dow Corning DC-4 silicone grease. I have had very good luck with this grease on my last NSX, where the brakes were used in winter snow, ice and sand conditions as well as at the racing circuit in 100F temperatures. I put a light coat on the piston surface and coat the square seal. It makes inserting the pistons quite easy. I also put a coat on the dust boot to aid in keeping water out of the piston cavity.

The "wrong" way. There is really no good way to get the dust boot lip into the groove on the caliper in this orientation.

The "right" way. It takes two people, but if one person stretches the opening and the other inserts the piston, it works quite well.

Note- these are the Centric branded dust boots. I recall that [MENTION=35590]Big McLargeHuge[/MENTION] was having fitment issues with his, but these fit perfectly. I wonder if they sent him the wrong ones by accident?

Last edited:

Brake Overhaul 08

Rear Calipers

The rear calipers were in rough shape. Releasing the piston resulted in a massive spill of rust-colored ancient brake fluid. Since I drained the fluid from the calipers prior to disassembly, it seems this fluid was trapped inside the piston itself? A mystery.

[HOLD]

The disassembled parts prior to cleaning. Again, despite the decrepit state of the calipers, somehow the pistons were ok.

Parts after a thorough cleaning.

[HOLD]

Paint coats going on.

[HOLD]

The OEM Honda rebuild kit parts. I'm still amazed that they provide three different greases for the parts.

Rear Calipers

The rear calipers were in rough shape. Releasing the piston resulted in a massive spill of rust-colored ancient brake fluid. Since I drained the fluid from the calipers prior to disassembly, it seems this fluid was trapped inside the piston itself? A mystery.

[HOLD]

The disassembled parts prior to cleaning. Again, despite the decrepit state of the calipers, somehow the pistons were ok.

Parts after a thorough cleaning.

[HOLD]

Paint coats going on.

[HOLD]

The OEM Honda rebuild kit parts. I'm still amazed that they provide three different greases for the parts.

Engine Refresh 36

Timing Mid-Covers

After a many-months wait from the factory, brand new production timing mid-covers arrived from Japan. These are the "A01" updated spec, which were revised to address cam gear rubbing noise on the original covers. Note- EMS shipping from Amayama has been restored.

A minor effort has turned into a major garage re-organization effort, so progress is slow. I hope by August to have [MENTION=34522]NSX_n00b[/MENTION]'s car at the paint shop and the S Zero up on jack stands once again to finish the subframe installation.

These are new production runs, so these date stamps don't make sense. 1994?

Timing Mid-Covers

After a many-months wait from the factory, brand new production timing mid-covers arrived from Japan. These are the "A01" updated spec, which were revised to address cam gear rubbing noise on the original covers. Note- EMS shipping from Amayama has been restored.

A minor effort has turned into a major garage re-organization effort, so progress is slow. I hope by August to have [MENTION=34522]NSX_n00b[/MENTION]'s car at the paint shop and the S Zero up on jack stands once again to finish the subframe installation.

These are new production runs, so these date stamps don't make sense. 1994?

Last edited:

Was ems shipping any cheaper than fedex? Last time I looked, the quote was more than both ups and fedex…

Was ems shipping any cheaper than fedex? Last time I looked, the quote was more than both ups and fedex…

It really depends...I tried to order 3 items from Amayama, they quoted me DHL for over $500 and told me if I eliminated one item they could do EMS for a more economical price. I removed the item and my EMS cost was $32. I then separately ordered the 3rd item and my EMS shipping cost was again only $32. So I have no idea why the 3 items together was causing problems.

But then I just tried to order 3 different items and now FedEx is cheapest at $90 and EMS is $131. So I think it's all just trial and error right now.

Was ems shipping any cheaper than fedex? Last time I looked, the quote was more than both ups and fedex…

This order (just the two covers) was about 50% cheaper via EMS.

Engine Refresh 37

Water Pump

The summer logjam is broken and work has resumed. Before placing the heads, I decided to complete some final engine block tasks since access was favorable. One is replacing the water pump.

This water pump only has about 2,000 miles on it, but is almost 8 years old. While it looks ok on the exterior, there was noticeable noise in the bearing and internal seals. This is from sitting for so many years in the stagnant coolant.

The new pump. Just a very light coat of silicone grease on the gasket.

The pump housing cleaned and prepped. Note the bolt holes are not done yet. My method is to chase the threads with a thread restorer, then run a solid brass wire brush and blow out with brake cleaner. Then hit with the vacuum. They were gleaming after this process.

The two styles of new bolts. They went in very smoothly thanks to the prep.

Installed and torqued to the spec. I bought new dowels but they were not necessary, as the old ones remained in place and did not come out with the old pump. VERY important for timing belt tension and alignment.

Water Pump

The summer logjam is broken and work has resumed. Before placing the heads, I decided to complete some final engine block tasks since access was favorable. One is replacing the water pump.

This water pump only has about 2,000 miles on it, but is almost 8 years old. While it looks ok on the exterior, there was noticeable noise in the bearing and internal seals. This is from sitting for so many years in the stagnant coolant.

The new pump. Just a very light coat of silicone grease on the gasket.

The pump housing cleaned and prepped. Note the bolt holes are not done yet. My method is to chase the threads with a thread restorer, then run a solid brass wire brush and blow out with brake cleaner. Then hit with the vacuum. They were gleaming after this process.

The two styles of new bolts. They went in very smoothly thanks to the prep.

Installed and torqued to the spec. I bought new dowels but they were not necessary, as the old ones remained in place and did not come out with the old pump. VERY important for timing belt tension and alignment.

Last edited:

Similar threads

- Replies

- 4

- Views

- 562

- Replies

- 8

- Views

- 655