Personally, I do want to keep the engine cover. In my eyes, the NSX is slowly becoming a classic car and I’d like to keep mine relatively stock looking.

If a new intake manifold is designed, I think it would be great if not only the plenum volume were optimized, but also the cross section and length of the runners. And it would be great if the runners were kept smooth – if no Z-shaped kinks or corners were introduced.

In a naturally aspirated application, FastraxTurbo did a dyno test with a stock intake manifold, with a ported intake manifold minus the VVIS plate, and with a ported intake manifold that had its center divider machined away and that had the outer walls of the gutted VVIS plate reinstalled (to maximize the volume of the plenum). Here were his results:

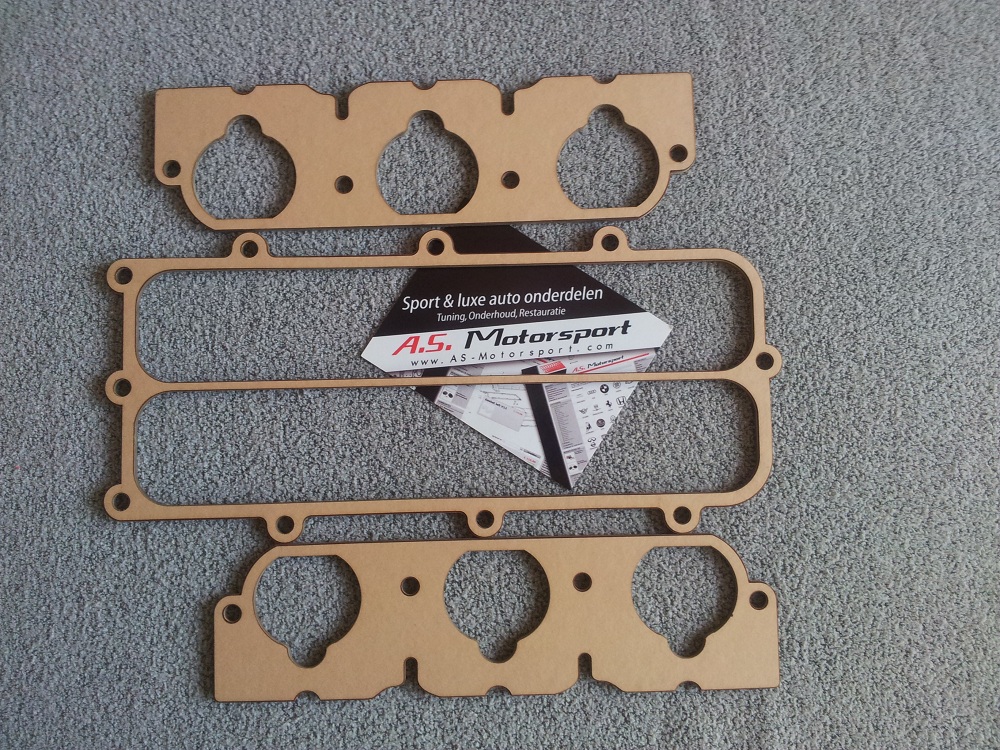

To visualize what those different intake manifold configurations look like, I sketched them based on one of Honda’s cutaway drawings.

For shits and giggles, I also sketched an OEM intake manifold with a one inch spacer between it and the cylinder heads and a correspondingly deeper plenum.

That looks like one big plenum! Since the mating surface of the intake manifold and cylinder heads is not at a right angle to the airflow, installing a spacer between the two unfortunately creates a Z-shaped kink in the runners. Depending on how thick the spacer is, the spray from the fuel injectors might start hitting the upper walls of the intake ports in the cylinder heads instead of shooting straight down the backs of the intake valves.

I wonder what intake manifold would be optimal for a turbo and what would be optimal for a naturally aspirated engine. If I remember correctly, turbo engines benefit from removing the VVIS system. Of the three configurations FastraxTurbo dyno tested in a naturally aspirated NSX, the one with the VVIS in place looks best overall. However, it would be great to have more n/a dyno measurements plus an understanding of why a certain design is best.