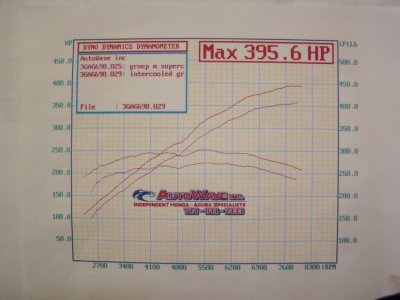

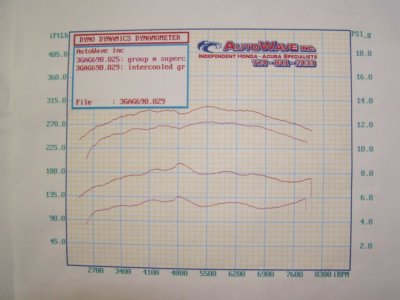

400hp prototype Eaton based S/C system

This is a picture of my prototype Eaton M90S based S/C system. This is an AEM EMS controlled air-to-water intercooled system with a highly modified stock intake manifold and cooling systems (engine & oil) capable of 10 plus psi boost depending on pulley size. Just the parts alone cost over $6700.00, raw materials over $450.00 and probably some 120 hours of fab time (not including design & development). I’d price it out at over $13K using a low ball 50$/hr machine/fab rate. I’m expecting around 440 hp with a nice flat torque curve characteristic of a positive displacement blower. Not necessarily the best bang for the buck, but at least I can say “I did it my way”.

However, if I reduced the boost to 5-6 psi, tossed the IC and used the stock intake manifold the cost comes down significantly. With some vendor support (better prices), I think I could offer a bolt on system for under $5.5K. It would include the following;

1) 3rd Gen Eaton M90S Blower w/bypass

2) AEM EMS with baseline S/C programming for otherwise “stock” NSX

3) Accufab 75mm throttle body with Ford TP sensor and harness adapter

4) 440cc RC Injectors

5) High volume fuel pump (optional)

6) 8 rib S/C belt

7) Machined idler pulleys (2)

8) Machined Crank Pully (8 rib belt)

9) Machined S/C mounting plate/belt tensioner (front)

10) Fabricated/machined S/C mounting plate (top)

11) Fabricated TB to S/C intake manifold w/throttle cable mount

12) Fabricated S/C exit manifold

13) Fabricated mandrel bent S/C to stock intake tube

14) Fabricated upper air box housing (need stock cover)

15) Fabricated EGR cover/rear S/C support plate & h/w

16) Fabricated S/C support strut

17) Modified fuel rail (need stock front rail)

18) Relocated oil fill cap to rear valve cover (need stock cover)

19) All necessary H/W, fuel line/fittings, hoses/clamps, etc

20) Engine cover trim template

This would be good for about 350 rwhp with an excellent powerband using a sophisticated Engine Management System. That’s a least $2.5K less than the Comptech and Gruppe M systems. Without the IC, I can get the system under a slightly modified engine cover. In addition, I’ve already designed a very efficient air-to-water IC system that can be added later allowing more boost at safer IATs (or cheaper go air-to-air).

To be fair, the Comptech has an advantage by virtue of a more efficient screw type S/C (I can adapt my mounting plate for any type S/C, but screw types are much more expensive). However, it’s impossible to intercool if you add more boost and you’re stuck with a very rudimentary fuel (not engine) management system that limits reliable output to the same 350hp or so. Even stock, most tuners recommend a high volume/pressure fuel pump since the stock item works VERY hard using the Comptech system. The Comptech is a nicer looking integrated system and fits completely under the engine cover, can’t argue with that. It's CARB approved too! (because they DO use the stock ECU).

The Gruppe M system has a better fuel (and ignition) management system than the Comptech (at least at boost), but it’s not programmable like the AEM. It can be intercooled but I haven’t seen it done with much success. The way the S/C is mounted results in a very torturious path from air cleaner to intake manifold. This drives air temps up and reduces flow and effective boost pressure. There’s no “cold air” intake and while my design won’t win any beauty contests, it’s a bit cleaner than the Gruppe M system. The Gruppe M system is also good for about 350hp as well, I know that for sure (where do you think I got that blower!).

Anyone interested????????

This is a picture of my prototype Eaton M90S based S/C system. This is an AEM EMS controlled air-to-water intercooled system with a highly modified stock intake manifold and cooling systems (engine & oil) capable of 10 plus psi boost depending on pulley size. Just the parts alone cost over $6700.00, raw materials over $450.00 and probably some 120 hours of fab time (not including design & development). I’d price it out at over $13K using a low ball 50$/hr machine/fab rate. I’m expecting around 440 hp with a nice flat torque curve characteristic of a positive displacement blower. Not necessarily the best bang for the buck, but at least I can say “I did it my way”.

However, if I reduced the boost to 5-6 psi, tossed the IC and used the stock intake manifold the cost comes down significantly. With some vendor support (better prices), I think I could offer a bolt on system for under $5.5K. It would include the following;

1) 3rd Gen Eaton M90S Blower w/bypass

2) AEM EMS with baseline S/C programming for otherwise “stock” NSX

3) Accufab 75mm throttle body with Ford TP sensor and harness adapter

4) 440cc RC Injectors

5) High volume fuel pump (optional)

6) 8 rib S/C belt

7) Machined idler pulleys (2)

8) Machined Crank Pully (8 rib belt)

9) Machined S/C mounting plate/belt tensioner (front)

10) Fabricated/machined S/C mounting plate (top)

11) Fabricated TB to S/C intake manifold w/throttle cable mount

12) Fabricated S/C exit manifold

13) Fabricated mandrel bent S/C to stock intake tube

14) Fabricated upper air box housing (need stock cover)

15) Fabricated EGR cover/rear S/C support plate & h/w

16) Fabricated S/C support strut

17) Modified fuel rail (need stock front rail)

18) Relocated oil fill cap to rear valve cover (need stock cover)

19) All necessary H/W, fuel line/fittings, hoses/clamps, etc

20) Engine cover trim template

This would be good for about 350 rwhp with an excellent powerband using a sophisticated Engine Management System. That’s a least $2.5K less than the Comptech and Gruppe M systems. Without the IC, I can get the system under a slightly modified engine cover. In addition, I’ve already designed a very efficient air-to-water IC system that can be added later allowing more boost at safer IATs (or cheaper go air-to-air).

To be fair, the Comptech has an advantage by virtue of a more efficient screw type S/C (I can adapt my mounting plate for any type S/C, but screw types are much more expensive). However, it’s impossible to intercool if you add more boost and you’re stuck with a very rudimentary fuel (not engine) management system that limits reliable output to the same 350hp or so. Even stock, most tuners recommend a high volume/pressure fuel pump since the stock item works VERY hard using the Comptech system. The Comptech is a nicer looking integrated system and fits completely under the engine cover, can’t argue with that. It's CARB approved too! (because they DO use the stock ECU).

The Gruppe M system has a better fuel (and ignition) management system than the Comptech (at least at boost), but it’s not programmable like the AEM. It can be intercooled but I haven’t seen it done with much success. The way the S/C is mounted results in a very torturious path from air cleaner to intake manifold. This drives air temps up and reduces flow and effective boost pressure. There’s no “cold air” intake and while my design won’t win any beauty contests, it’s a bit cleaner than the Gruppe M system. The Gruppe M system is also good for about 350hp as well, I know that for sure (where do you think I got that blower!).

Anyone interested????????

Attachments

Last edited: