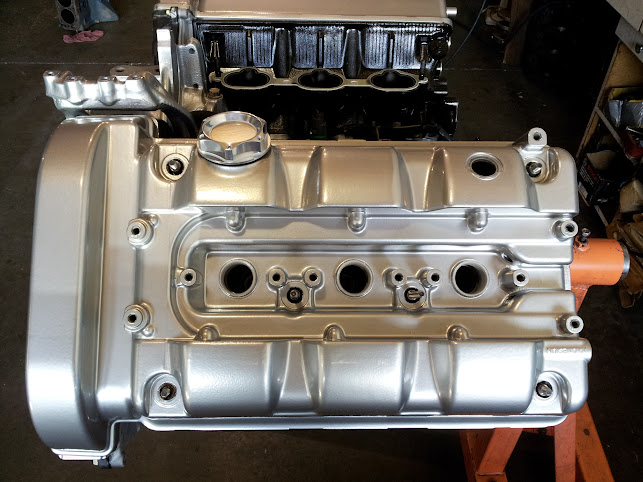

Depending what I do for valve stuff, the engine might be ready in a week or two. So, time to get off my rear end and get to busy on this car.

Not directly related to the engine build, but a necessary component when making more power is the cooling system. I have all new hoses, and a new radiator for this (I'm reusing my aluminum Dali expansion tank).

When I take the front bumper off later, I'll fabricate a nicer airbox to the radiator (ala what John@Microsoft did), but for now, I cleaned up the front end...

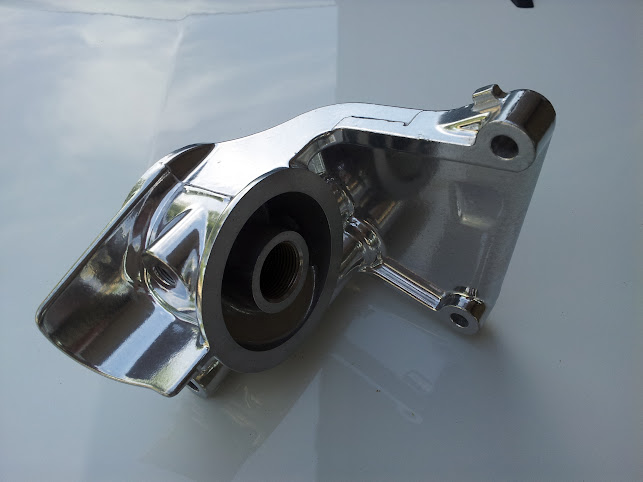

And will be putting this in:

It's the PWR #2419 model for the NSX. I got it from Dali and it looks like a nice setup. I did a little trimming around the hose barbs, and also at the far reaches of the shroud. I'm not concerned with stationary cooling so much as I am with at-speed cooling when I'm producing power. So, I tried to swiss-cheese the shroud but retain some strength where it sits against the radiator at the edges. I think I accomplished that.

Just trying to get the front finished up... Still need to install the rebuilt rack by D1guy and redo my ABS-delete brake lines.

Not directly related to the engine build, but a necessary component when making more power is the cooling system. I have all new hoses, and a new radiator for this (I'm reusing my aluminum Dali expansion tank).

When I take the front bumper off later, I'll fabricate a nicer airbox to the radiator (ala what John@Microsoft did), but for now, I cleaned up the front end...

And will be putting this in:

It's the PWR #2419 model for the NSX. I got it from Dali and it looks like a nice setup. I did a little trimming around the hose barbs, and also at the far reaches of the shroud. I'm not concerned with stationary cooling so much as I am with at-speed cooling when I'm producing power. So, I tried to swiss-cheese the shroud but retain some strength where it sits against the radiator at the edges. I think I accomplished that.

Just trying to get the front finished up... Still need to install the rebuilt rack by D1guy and redo my ABS-delete brake lines.

![eni[1].jpg](/data/attachments/68/68250-78f7046ad779a33b714f314697d2f902.jpg)