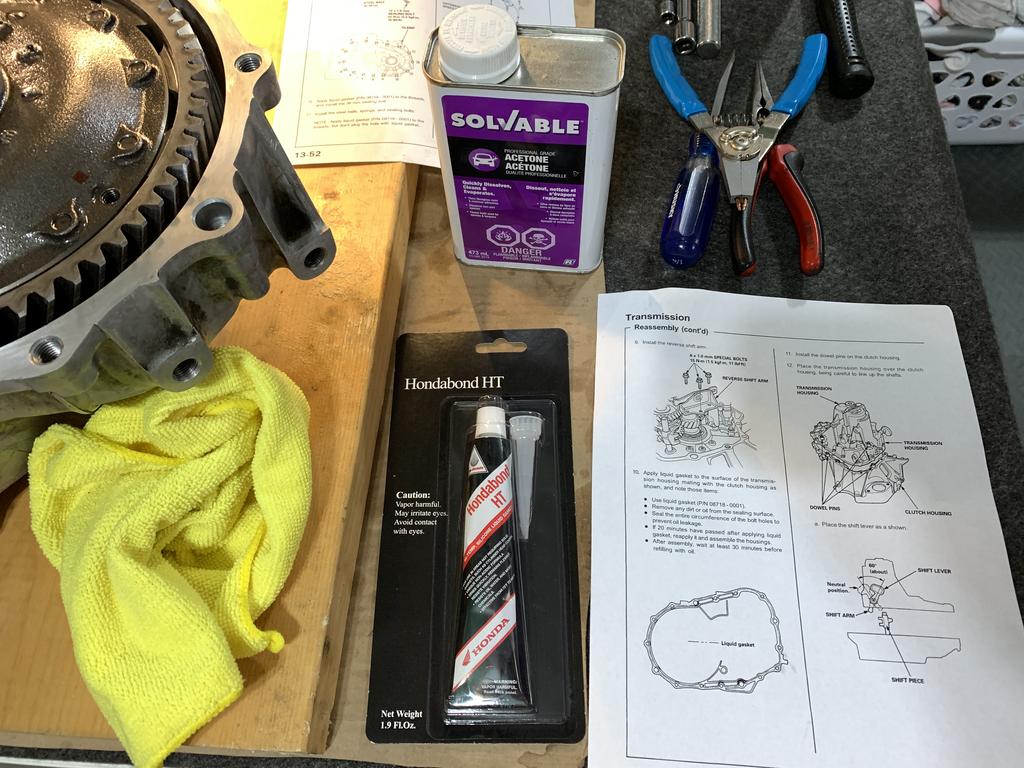

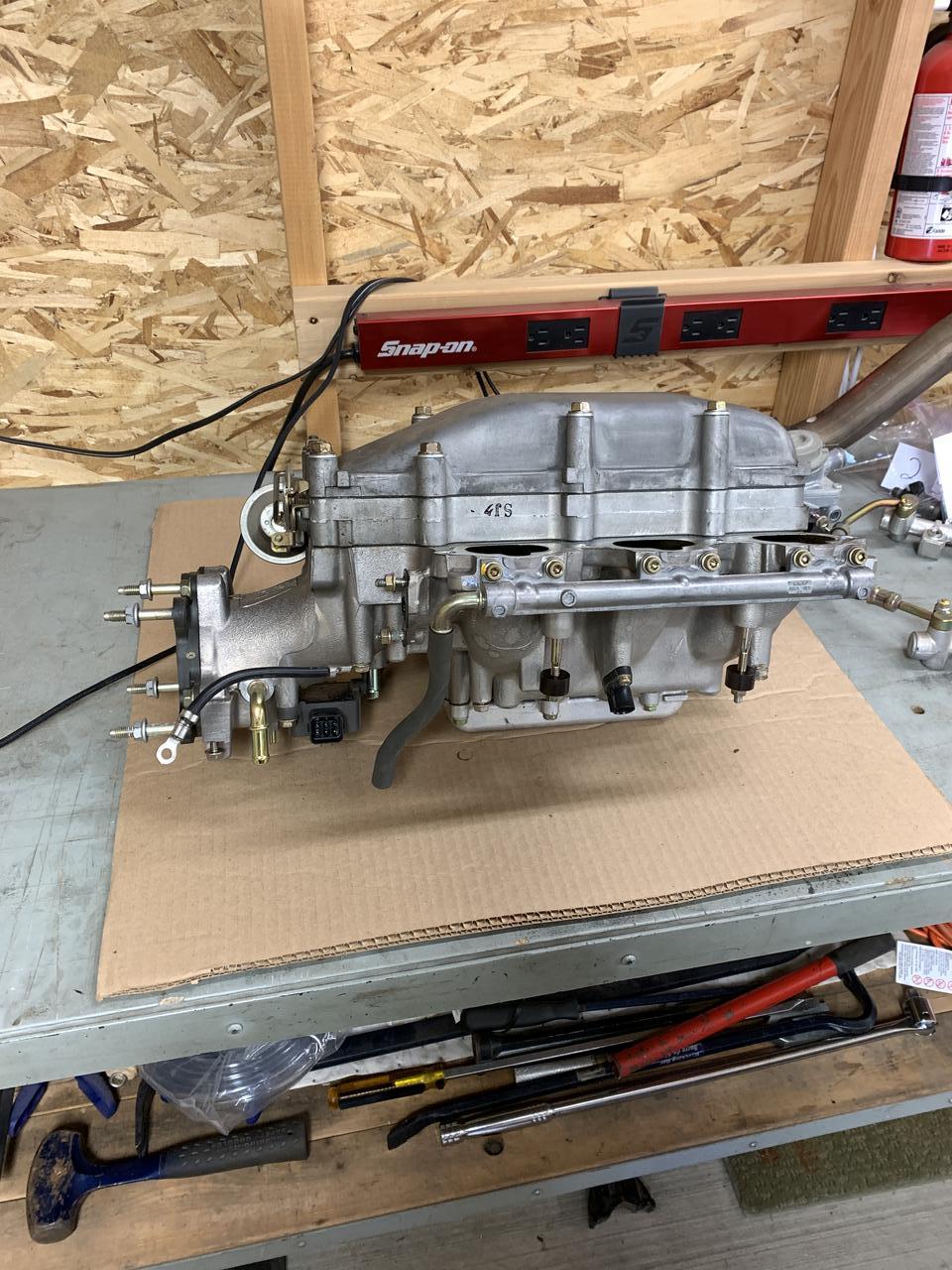

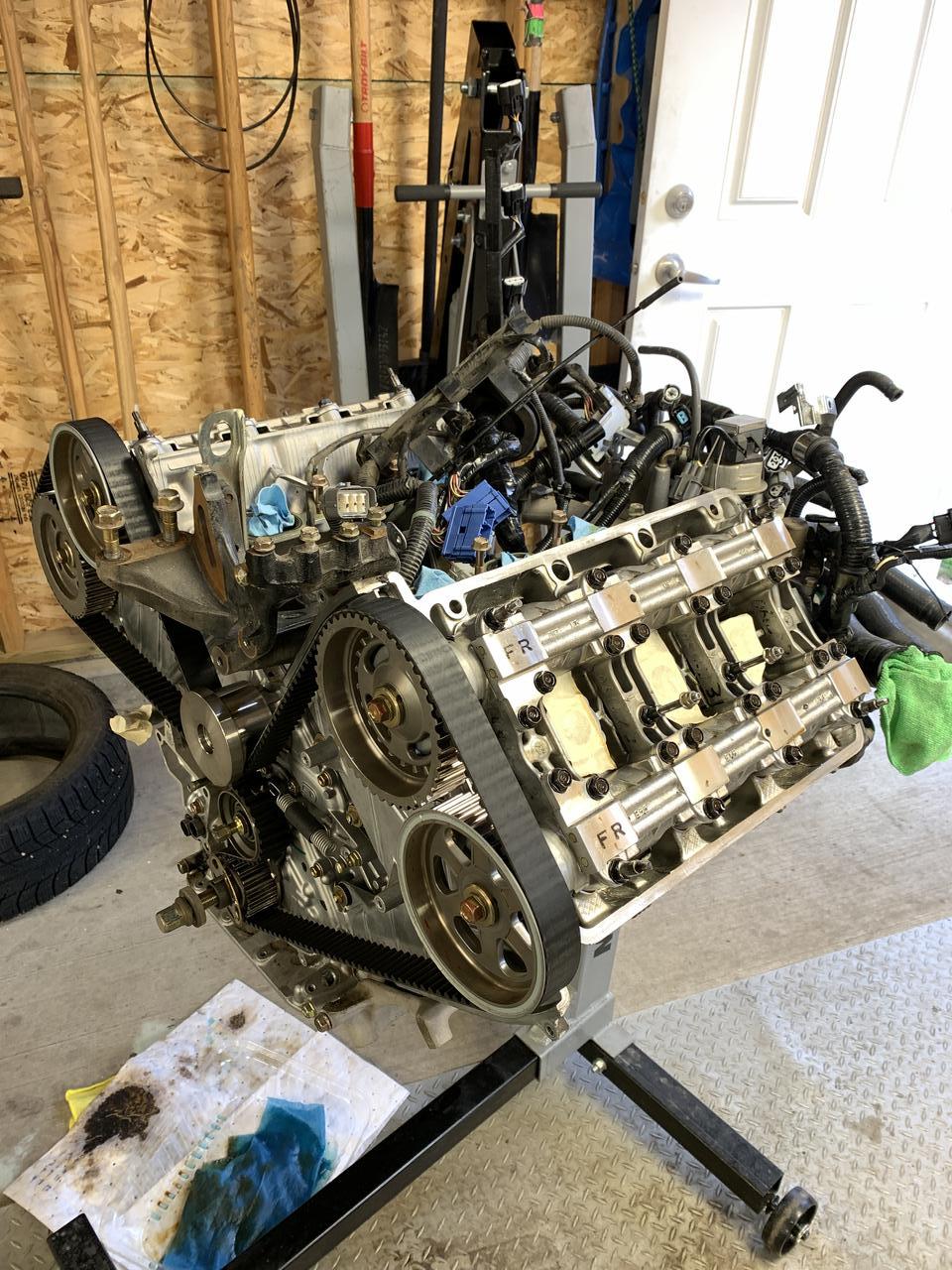

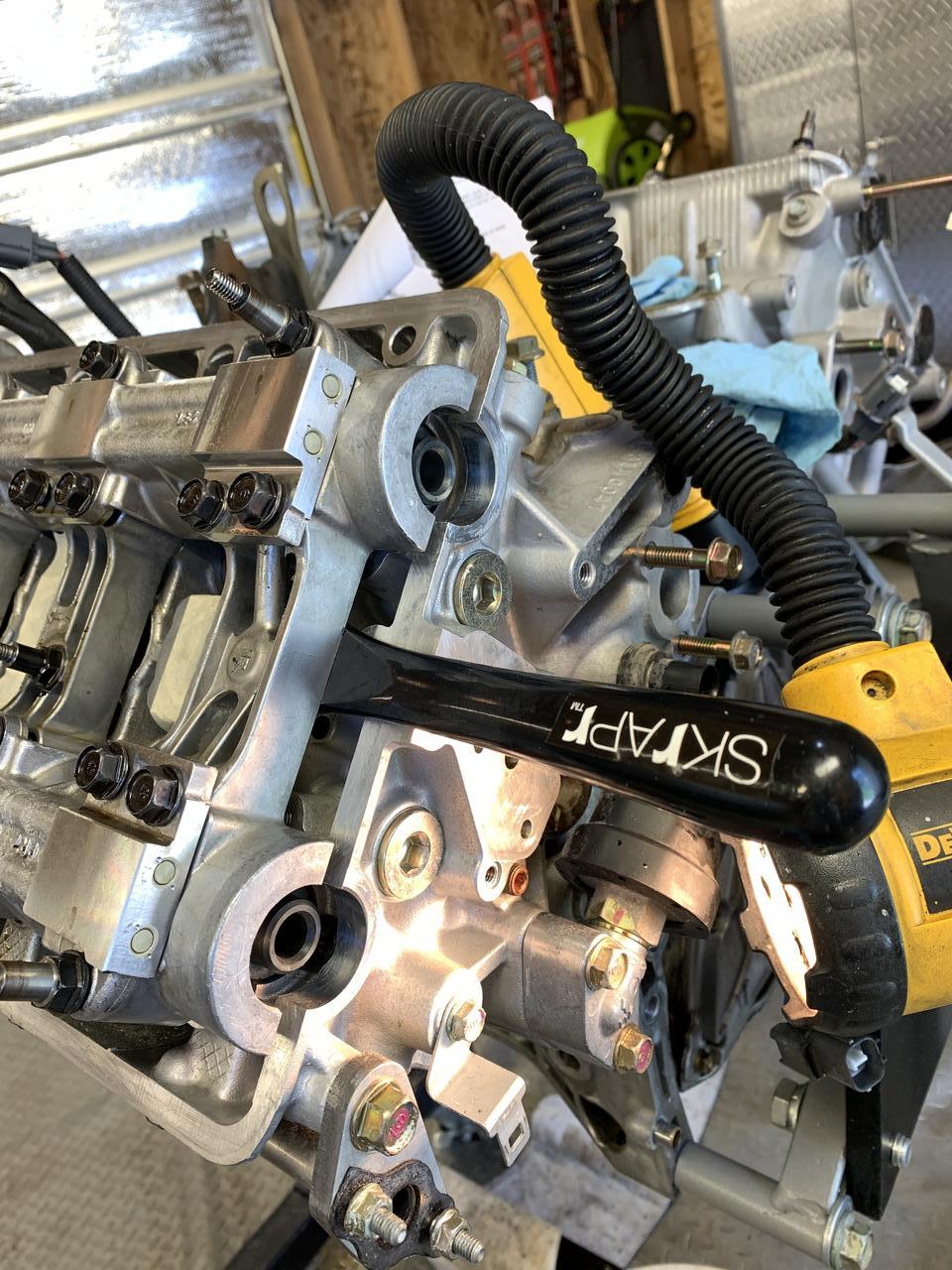

Now to start putting everything back together for the final time.

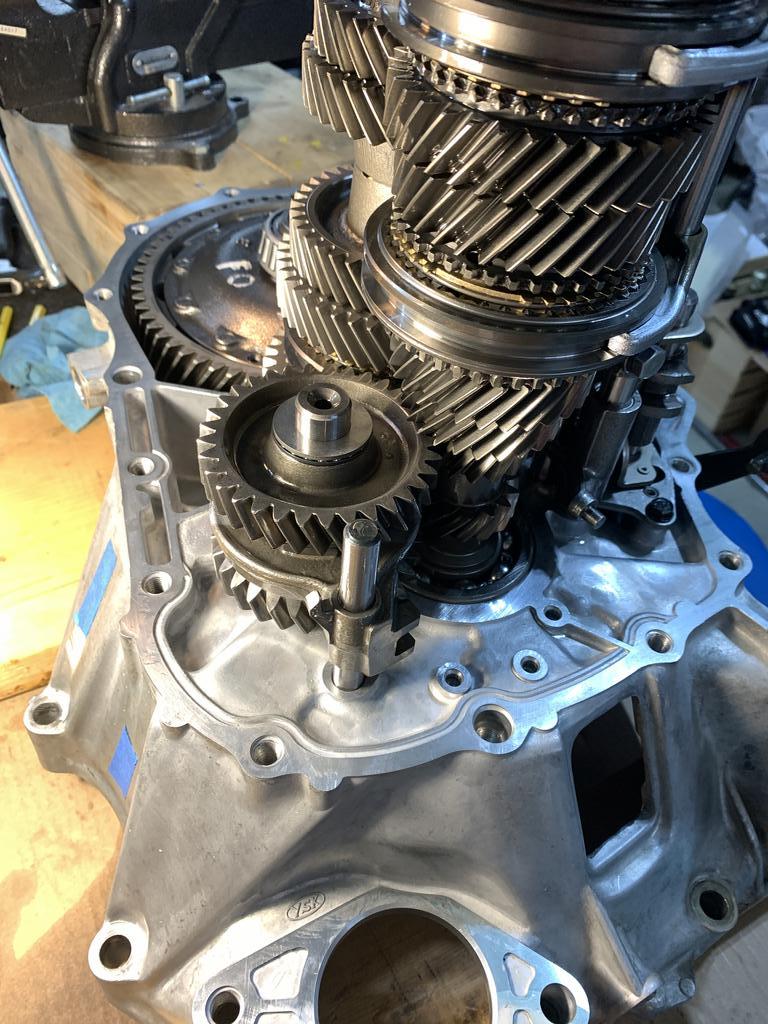

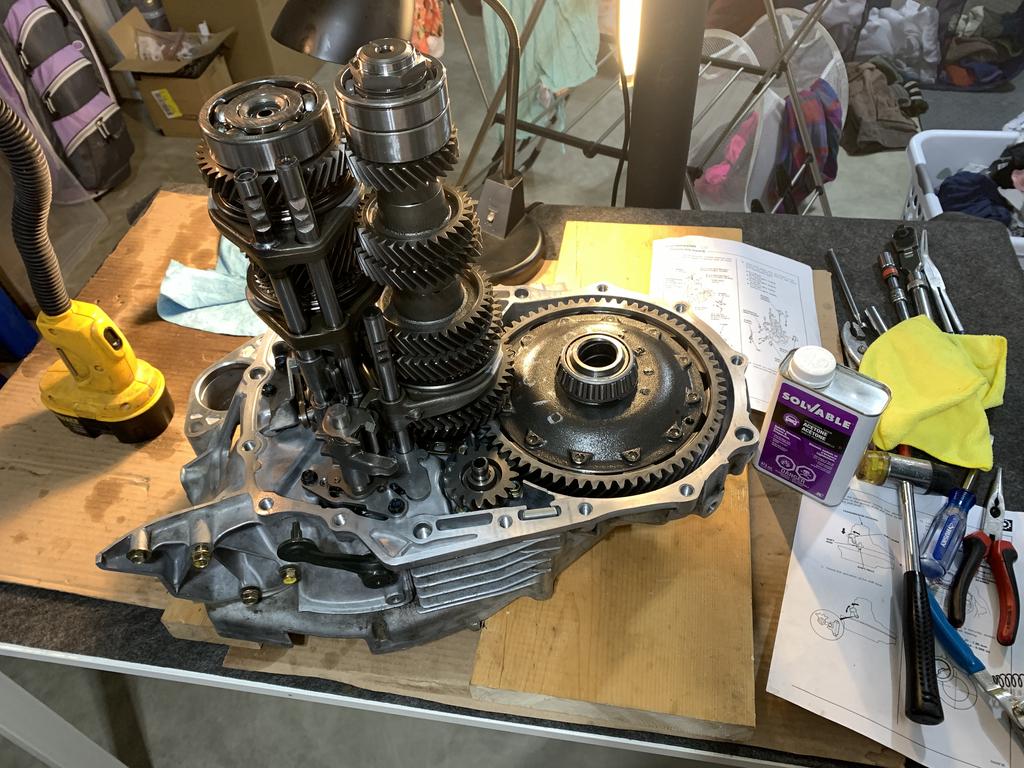

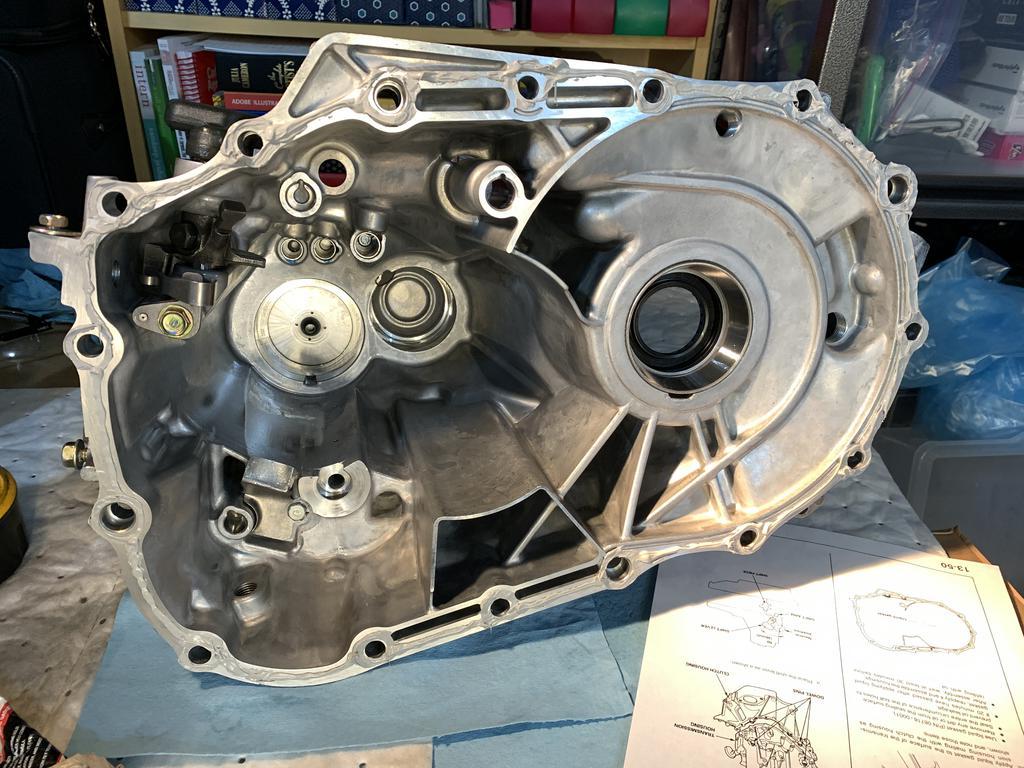

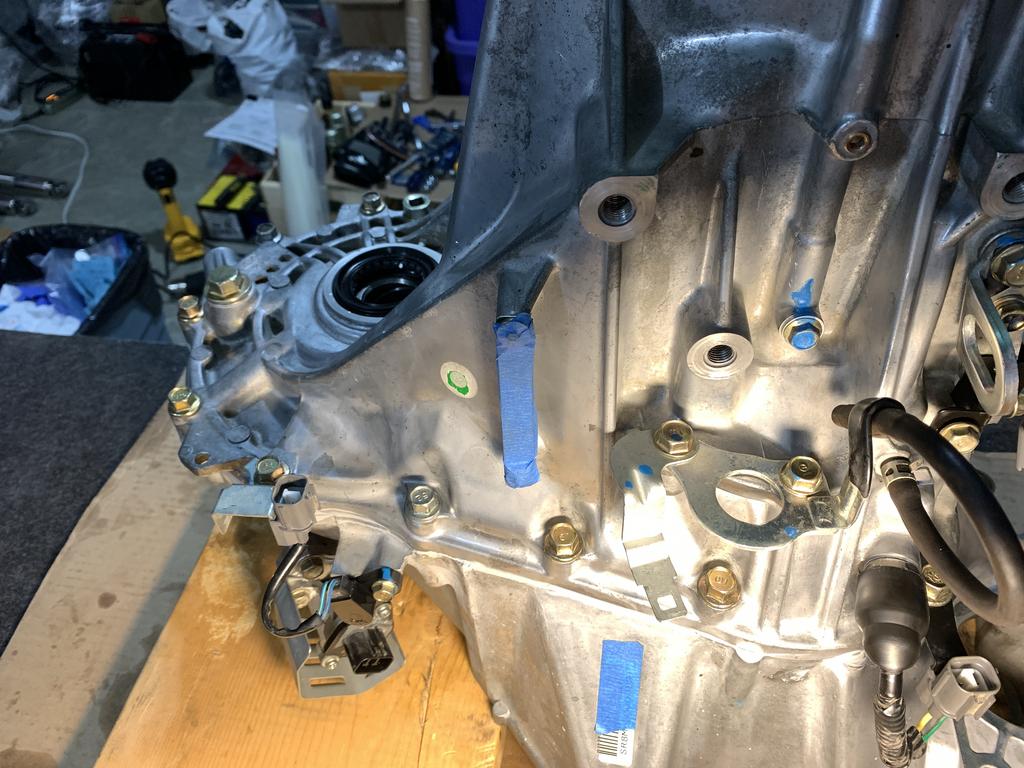

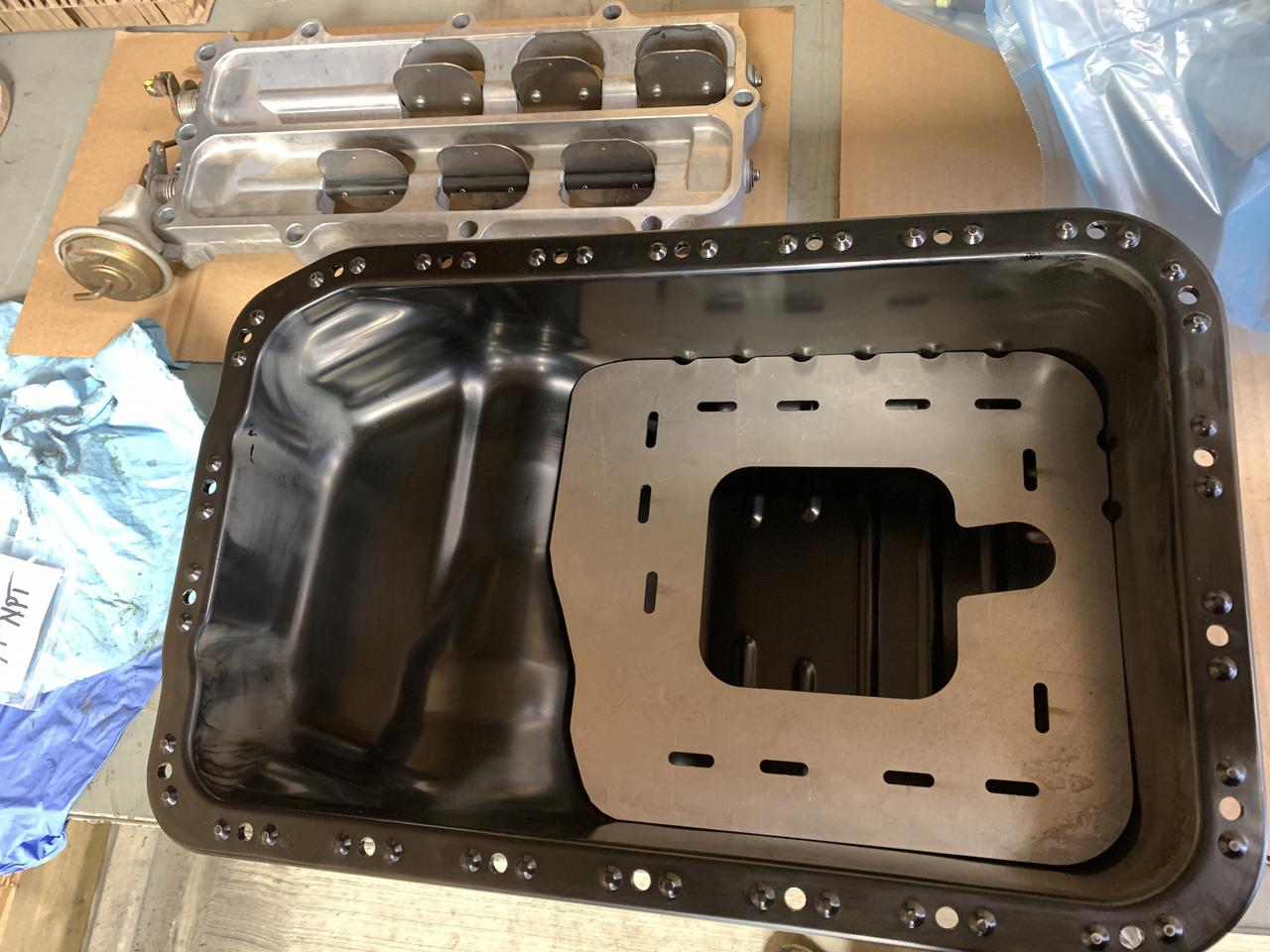

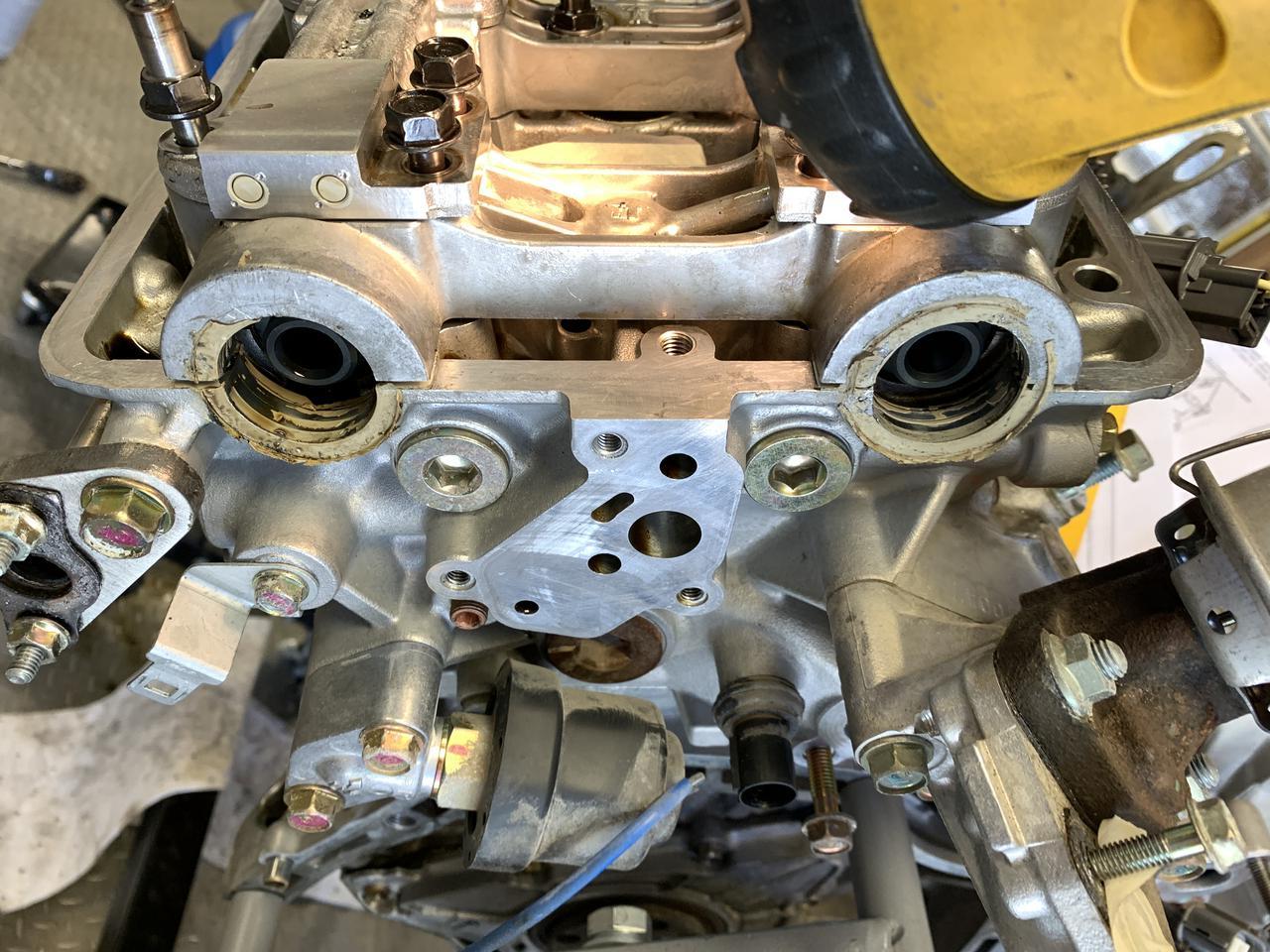

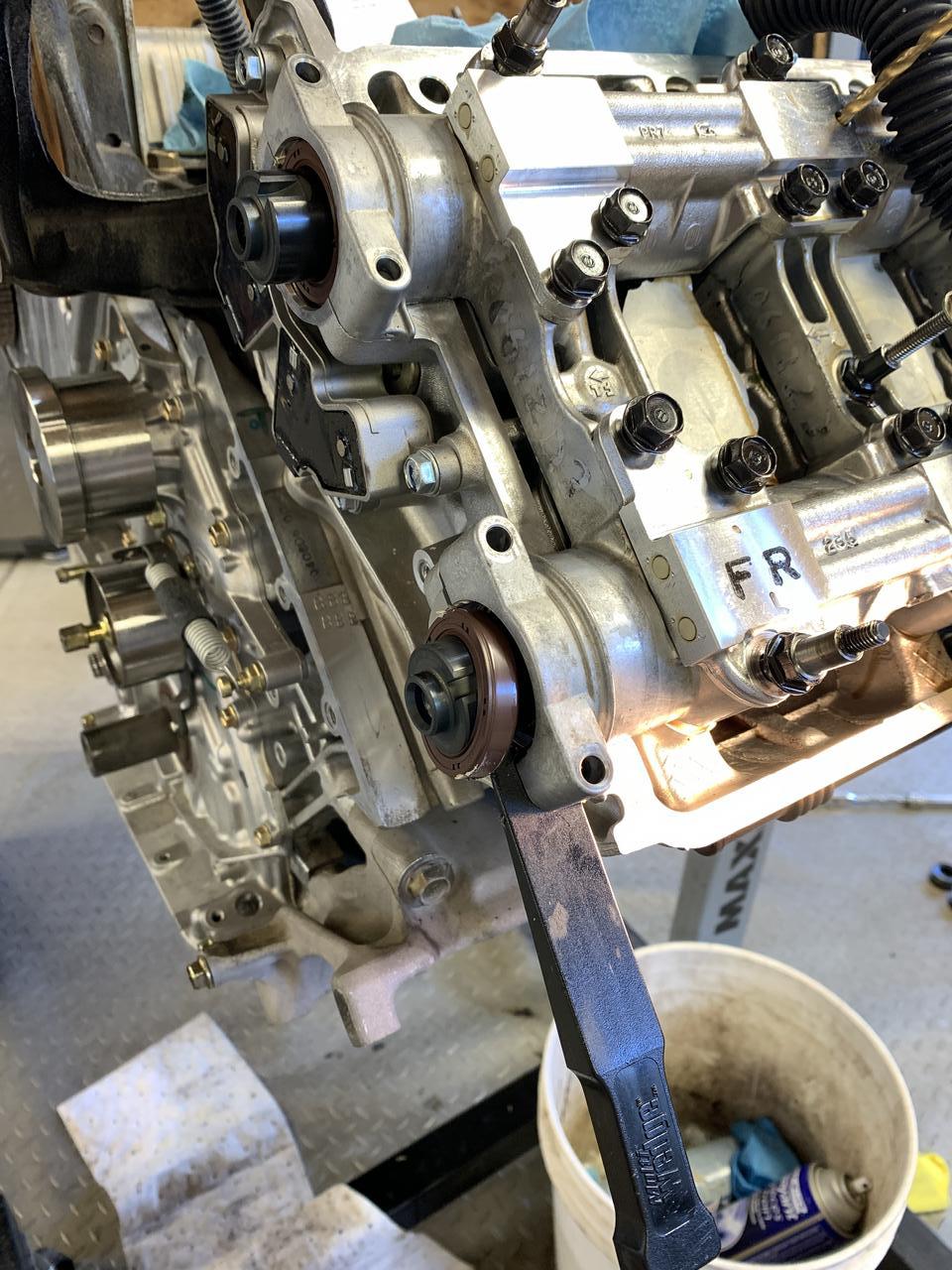

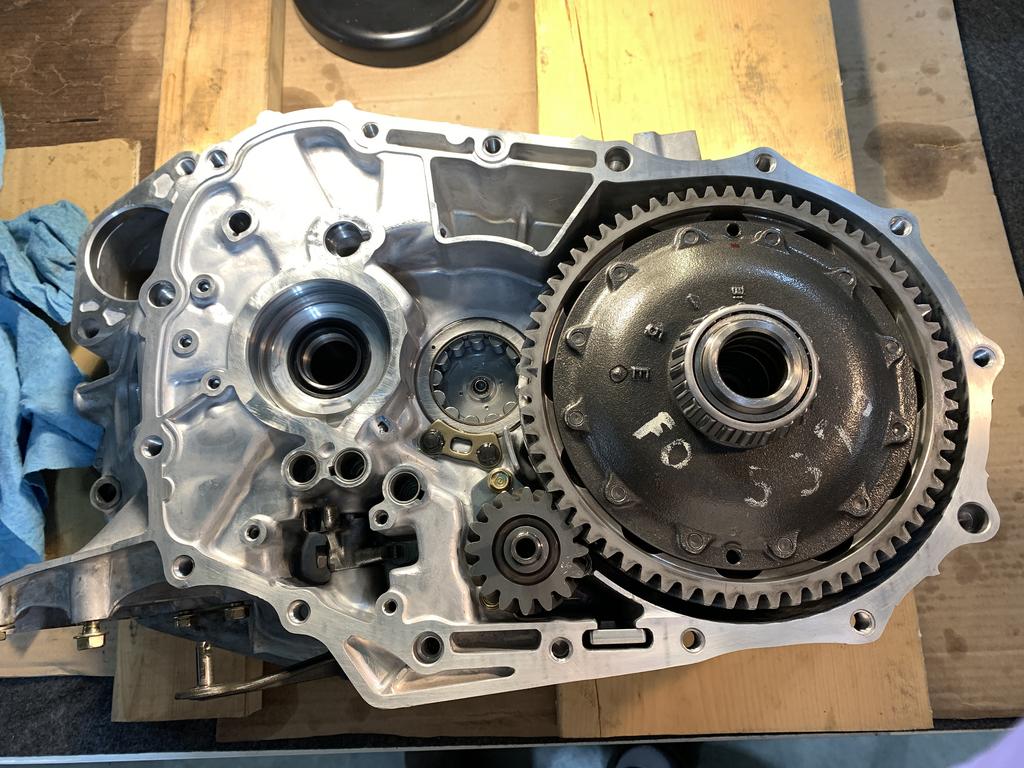

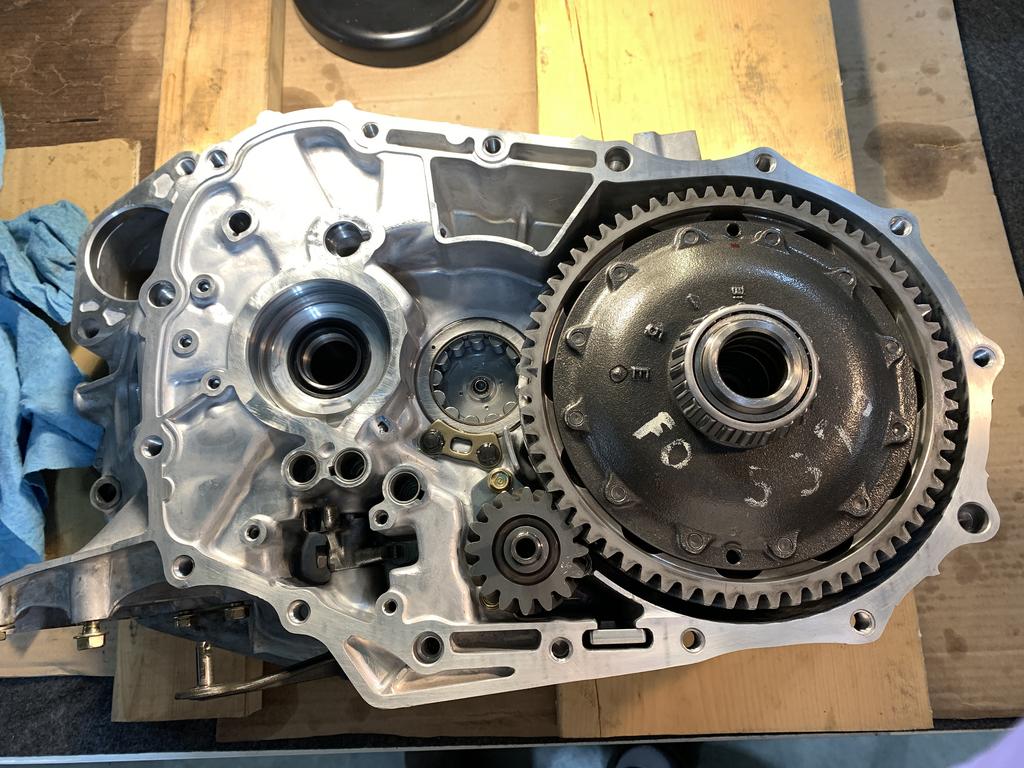

First the differential

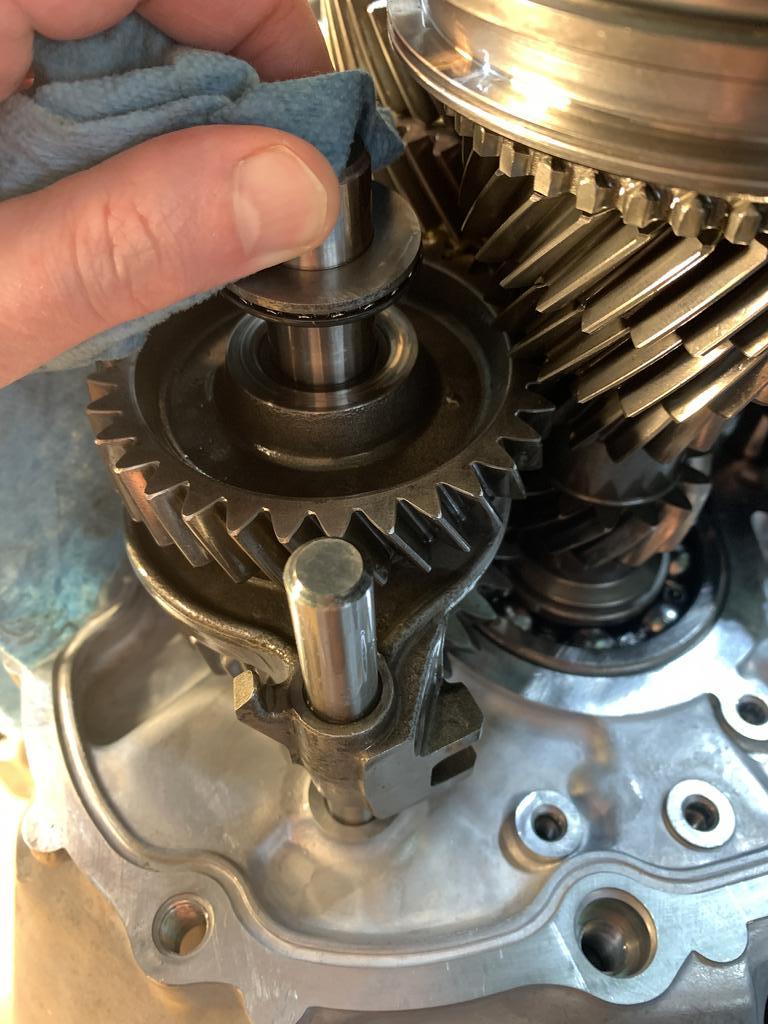

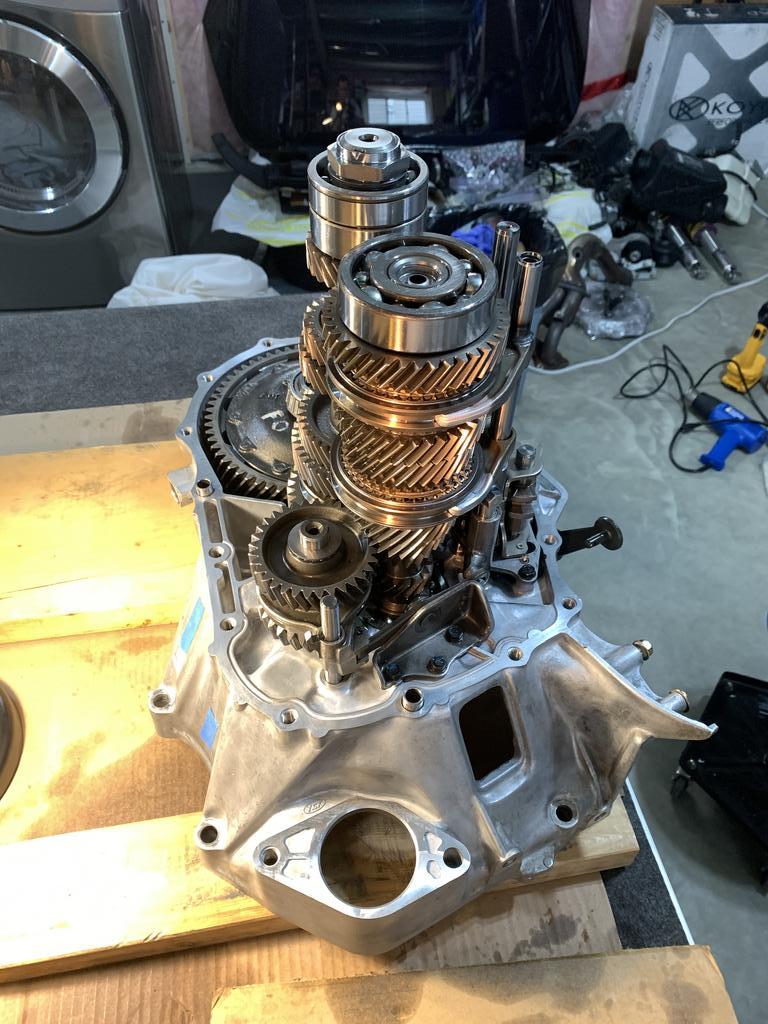

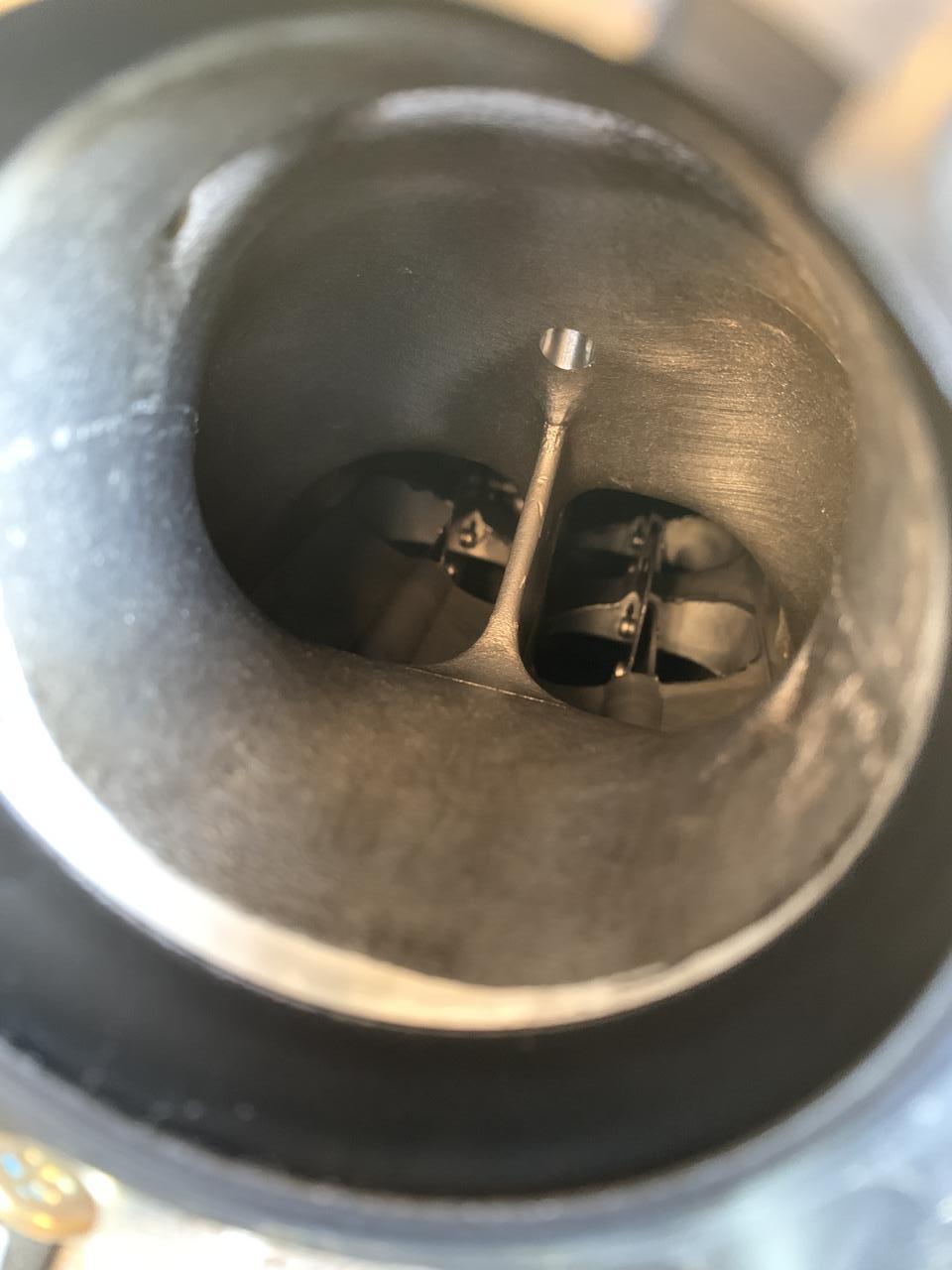

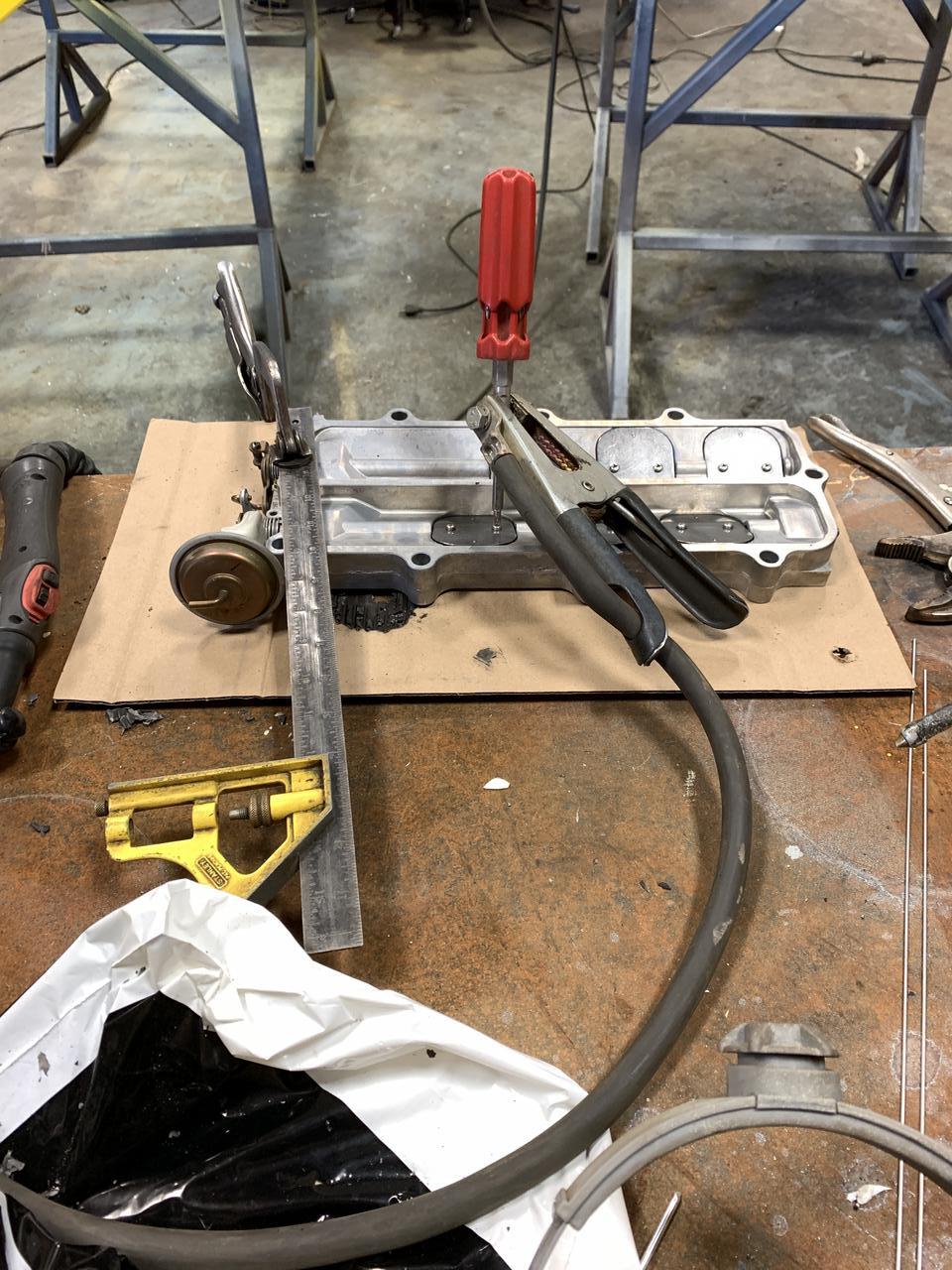

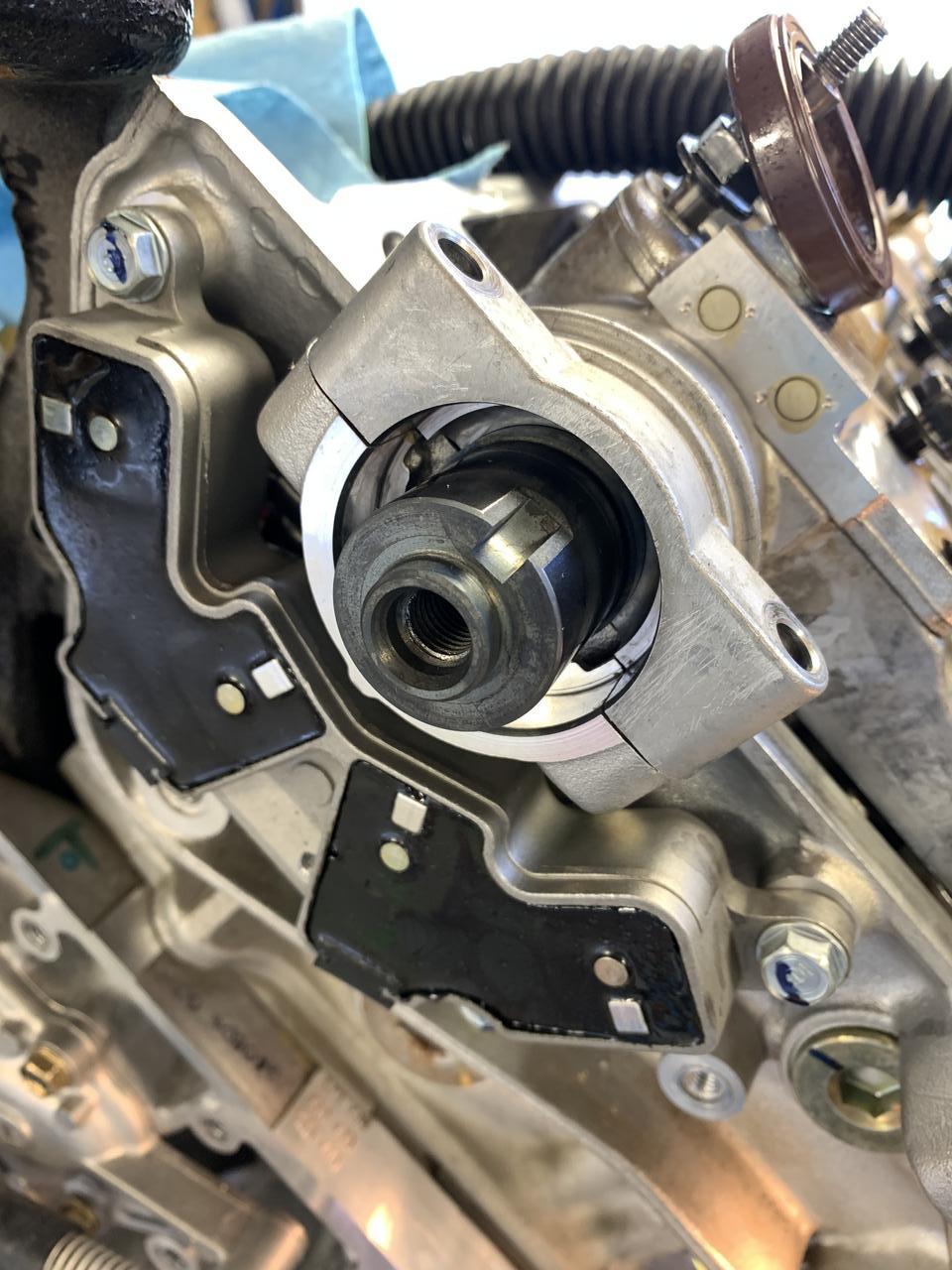

Then the forum approved zip tie method for the shafts and shift forks. I can honestly say it worked great.

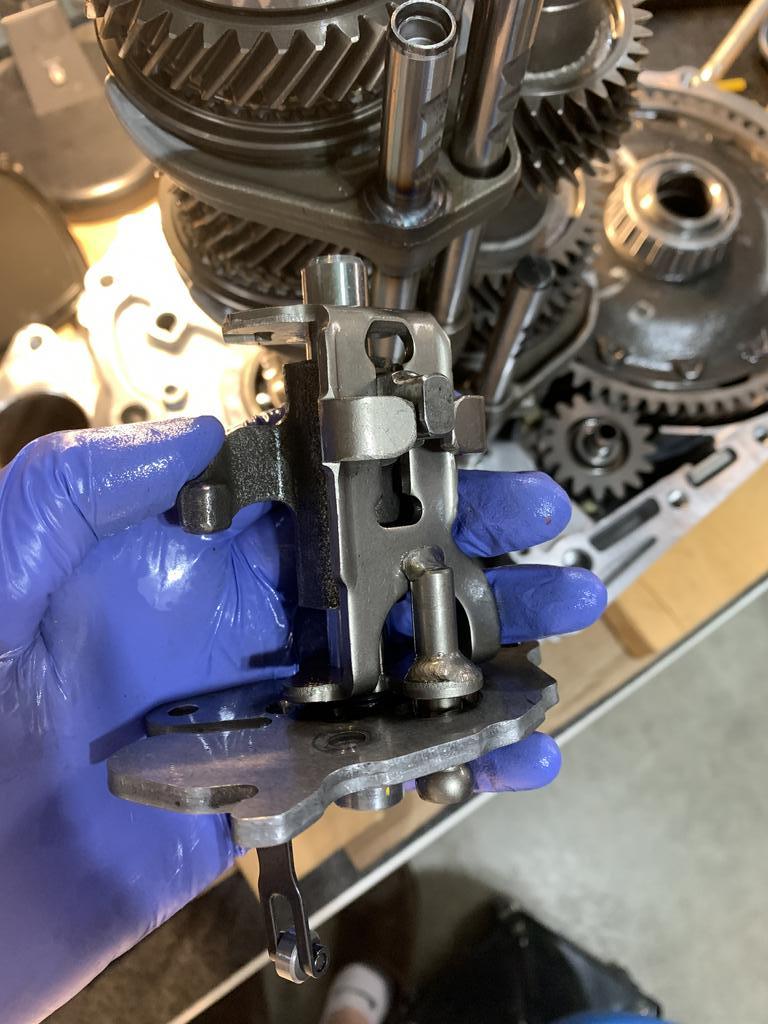

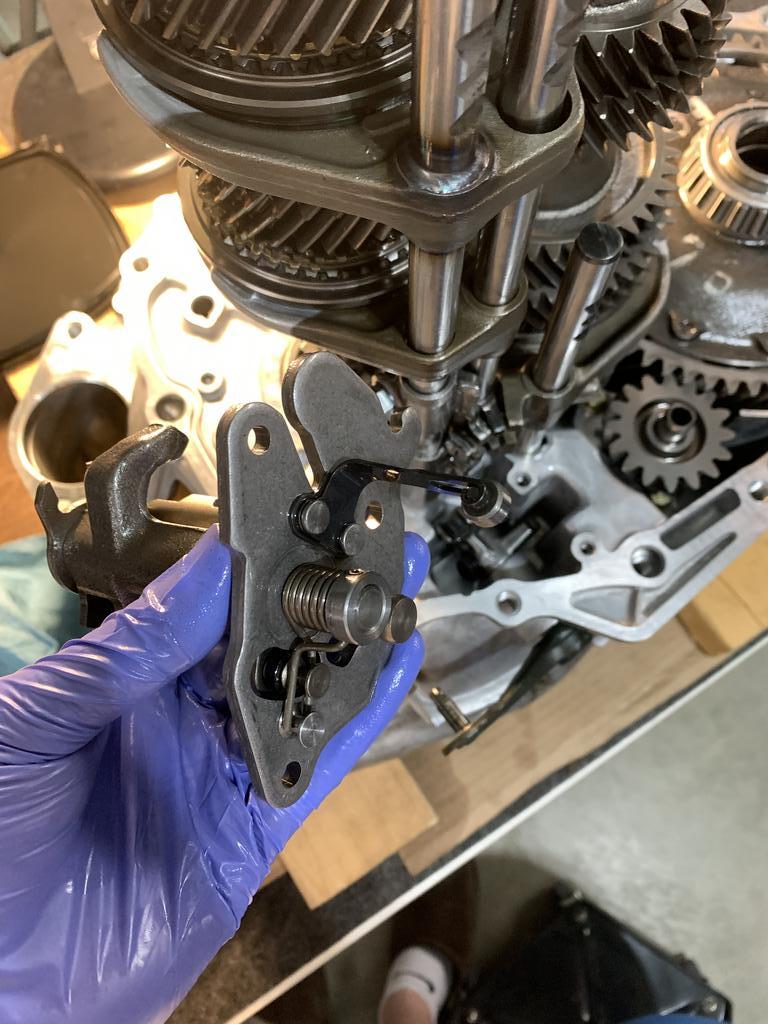

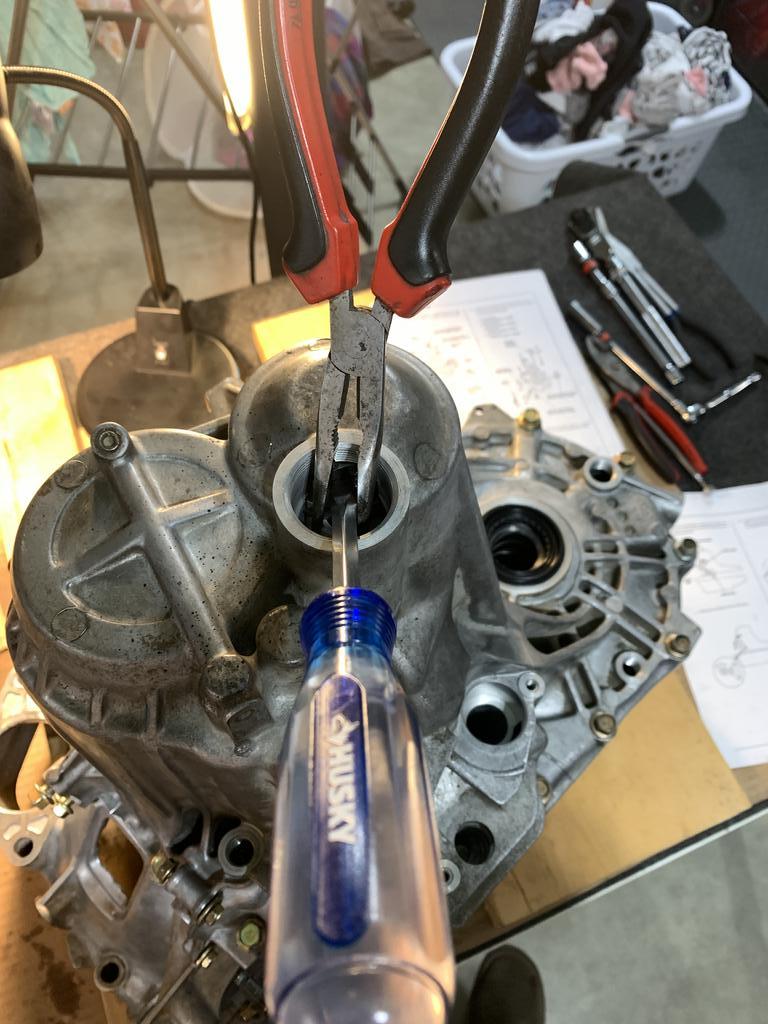

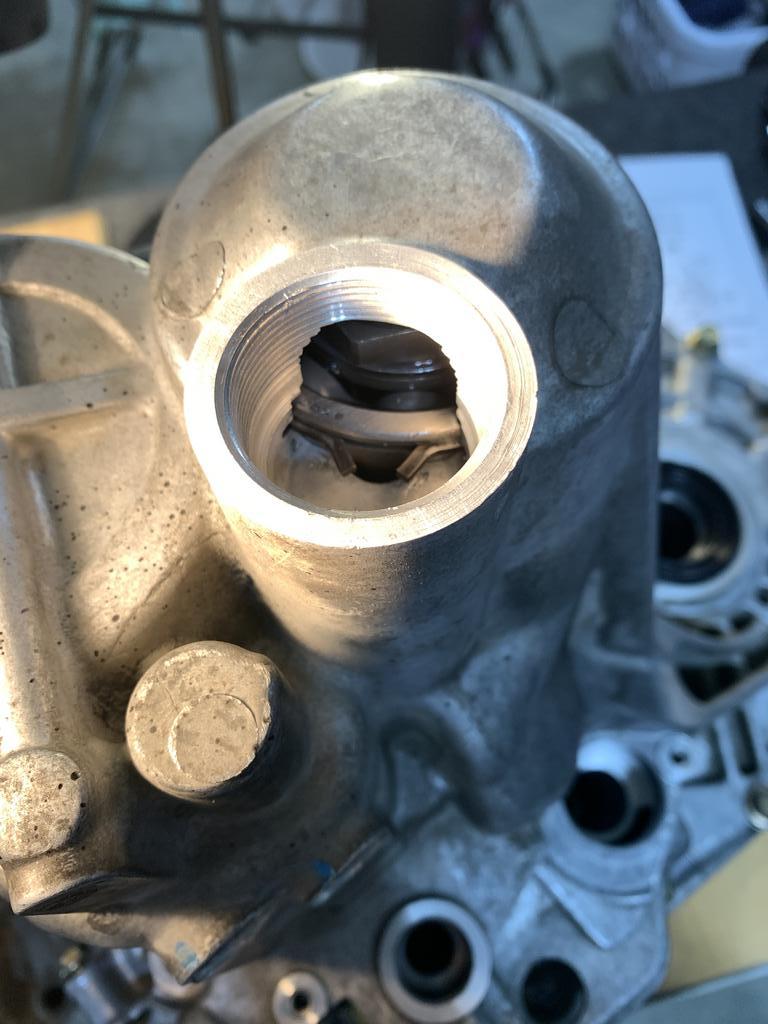

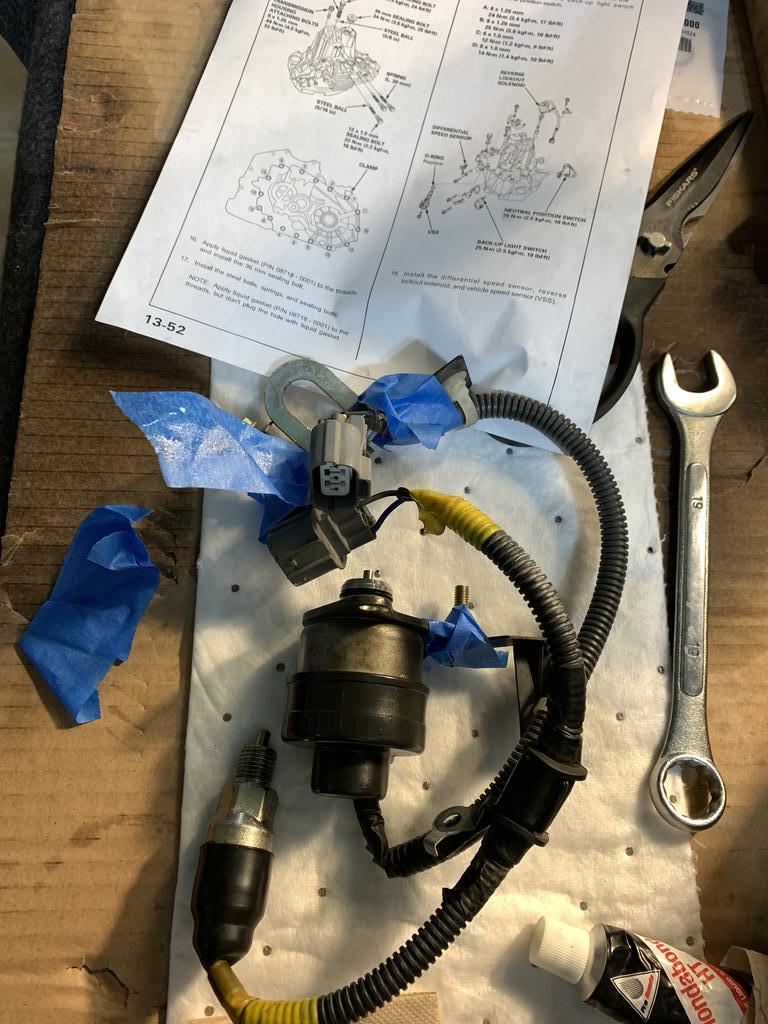

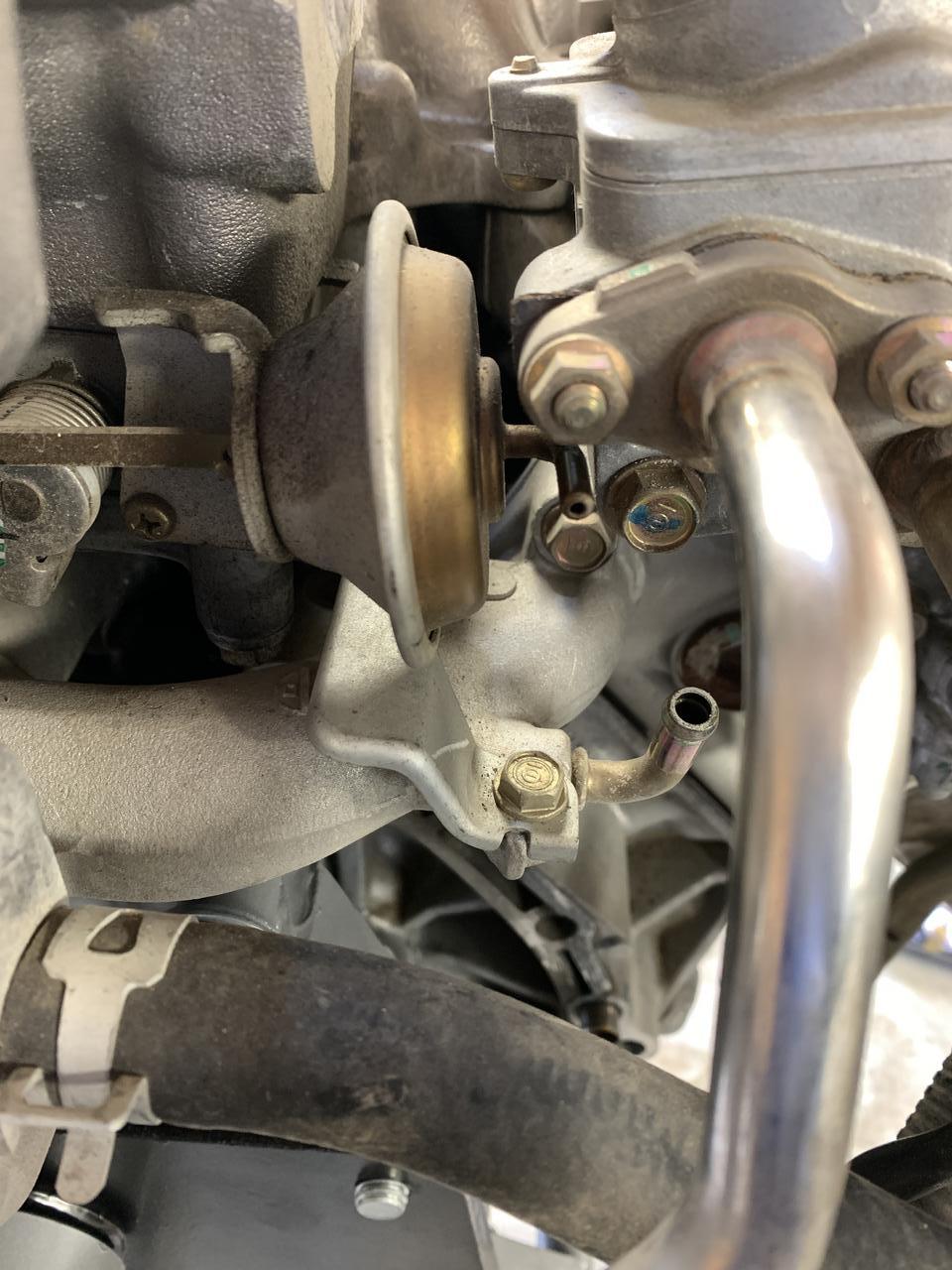

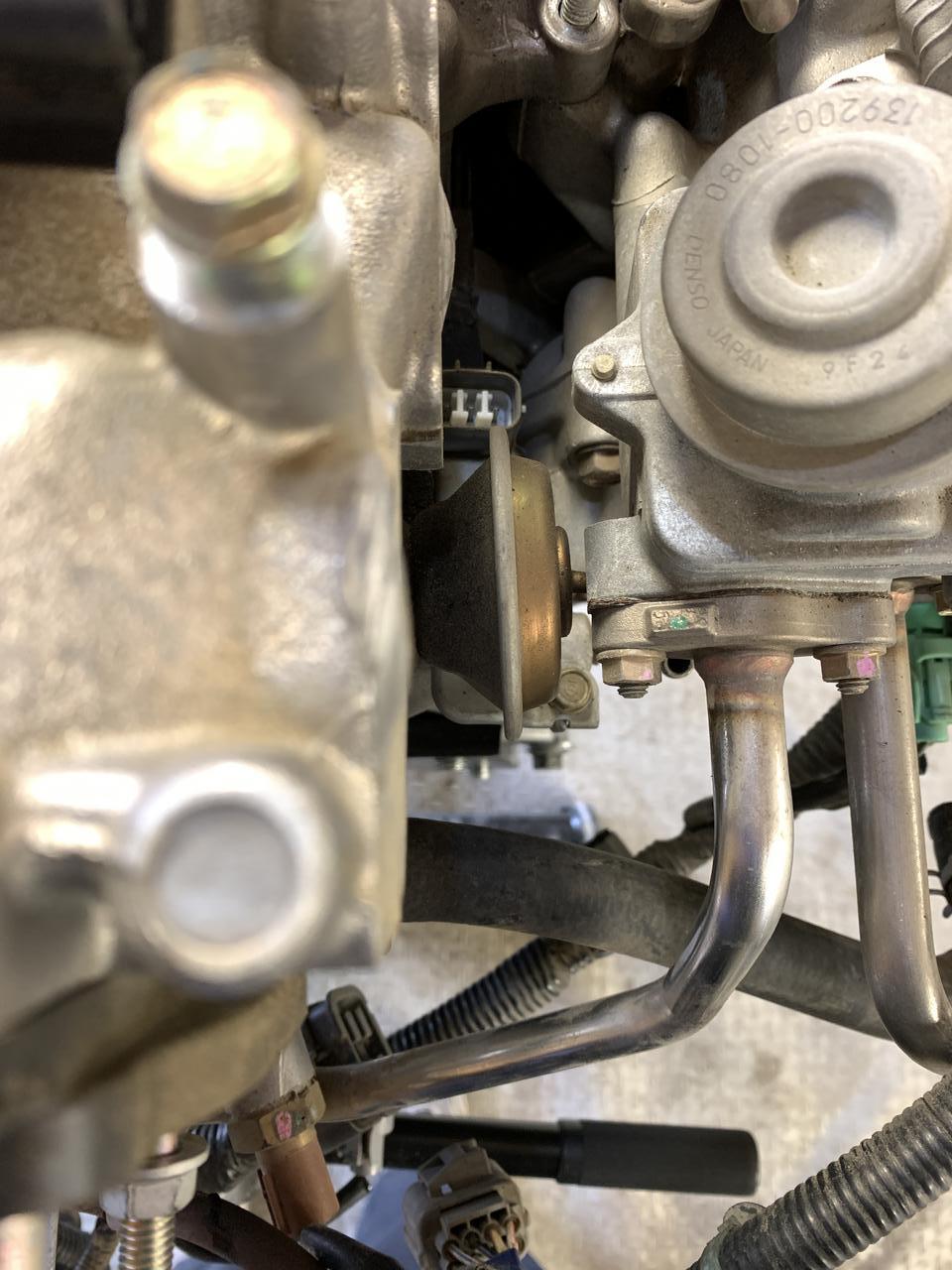

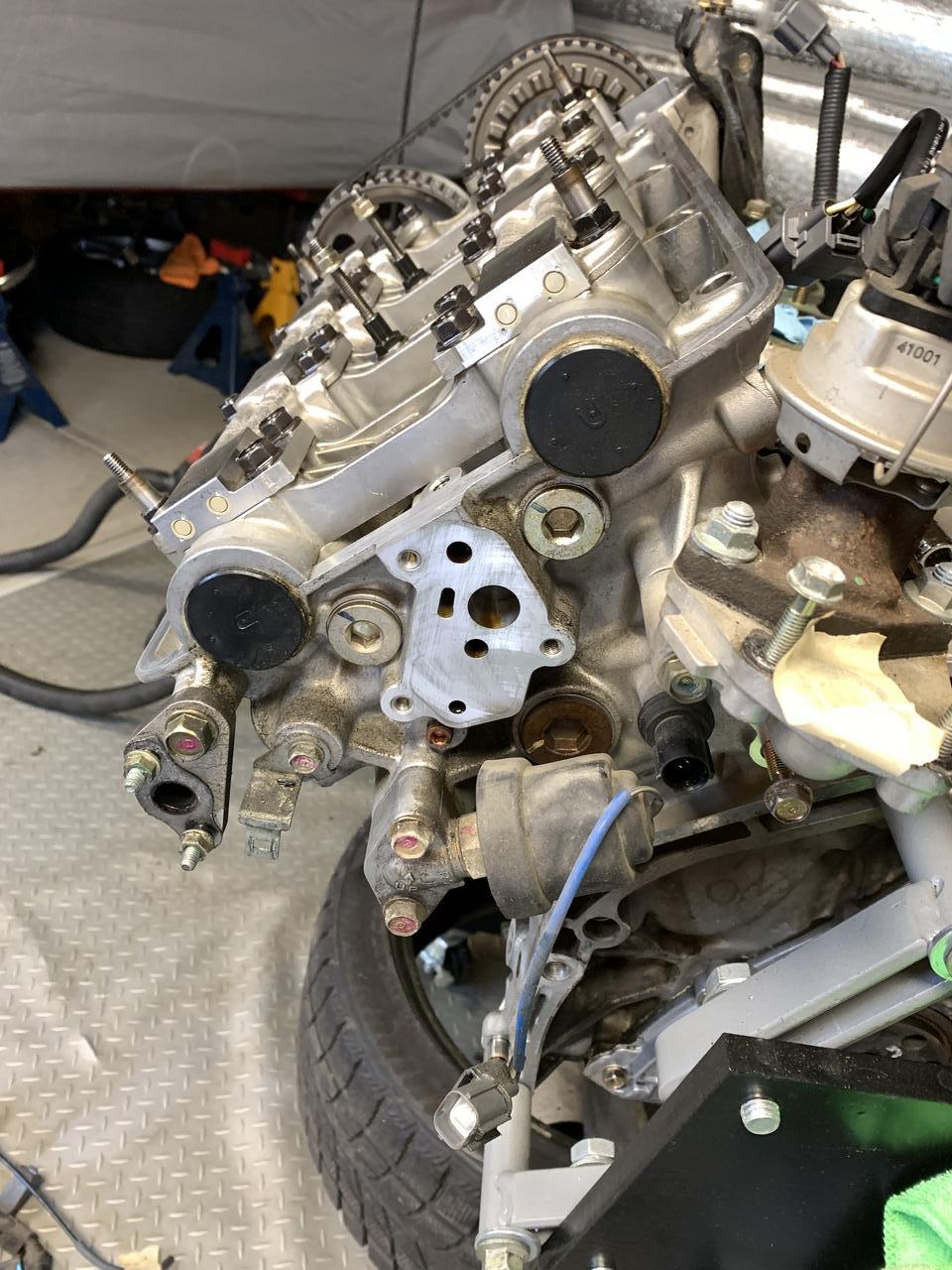

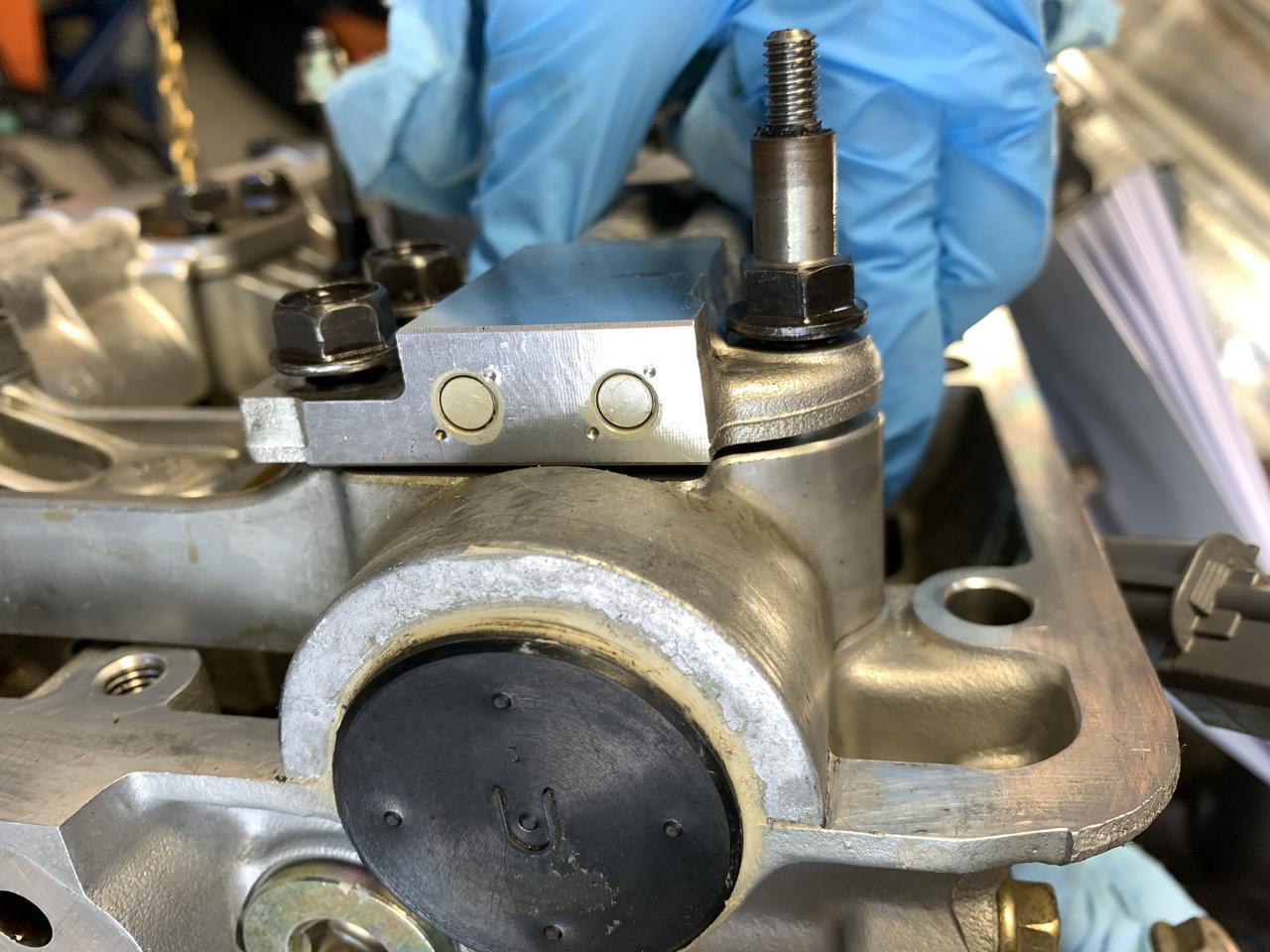

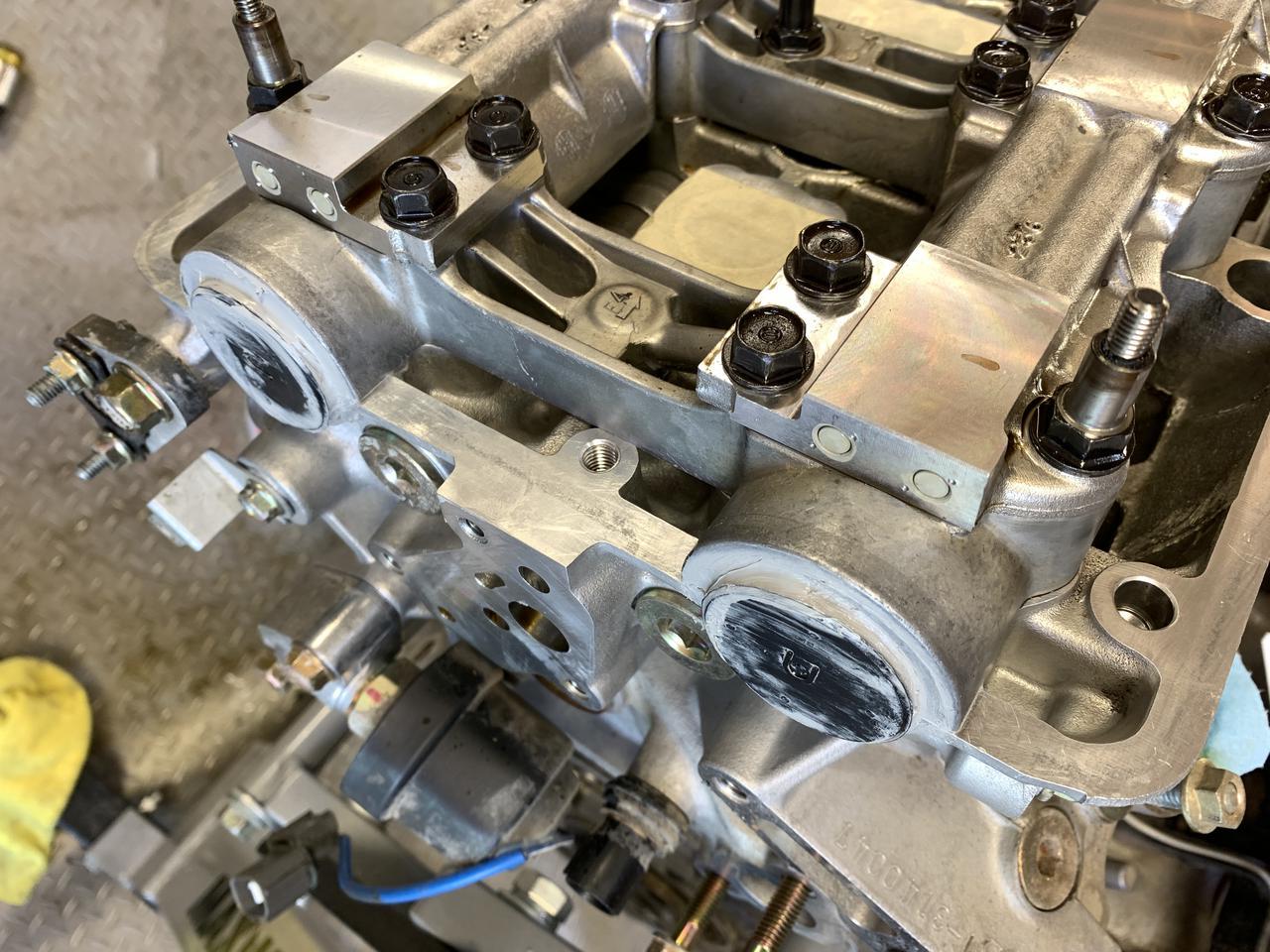

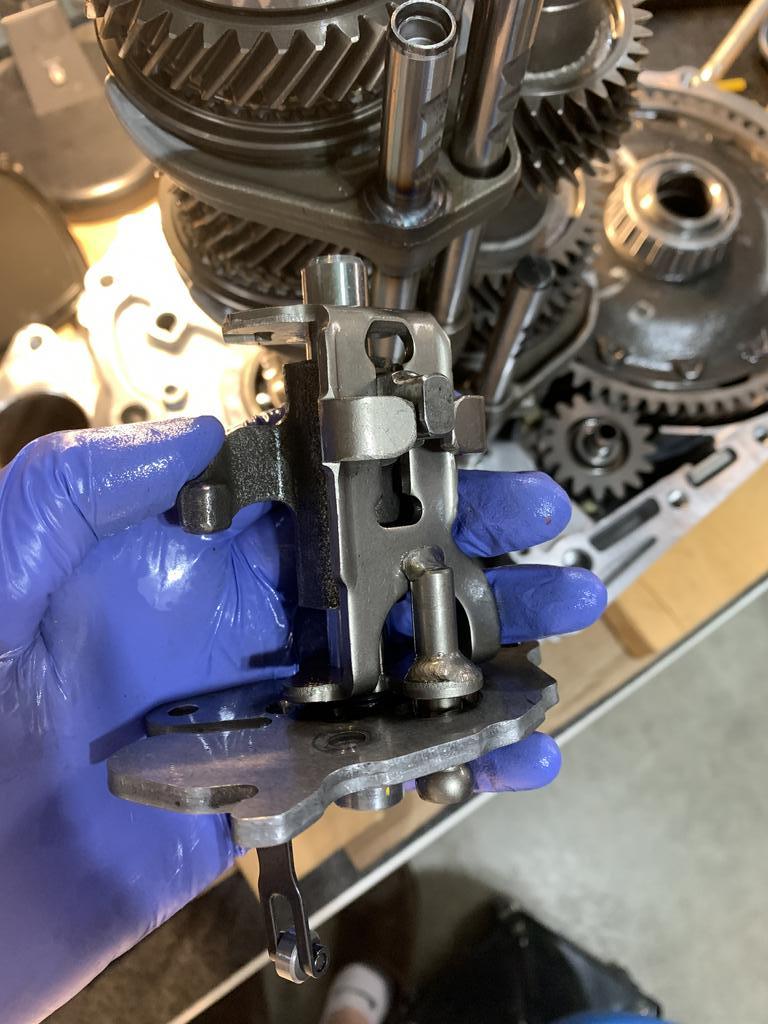

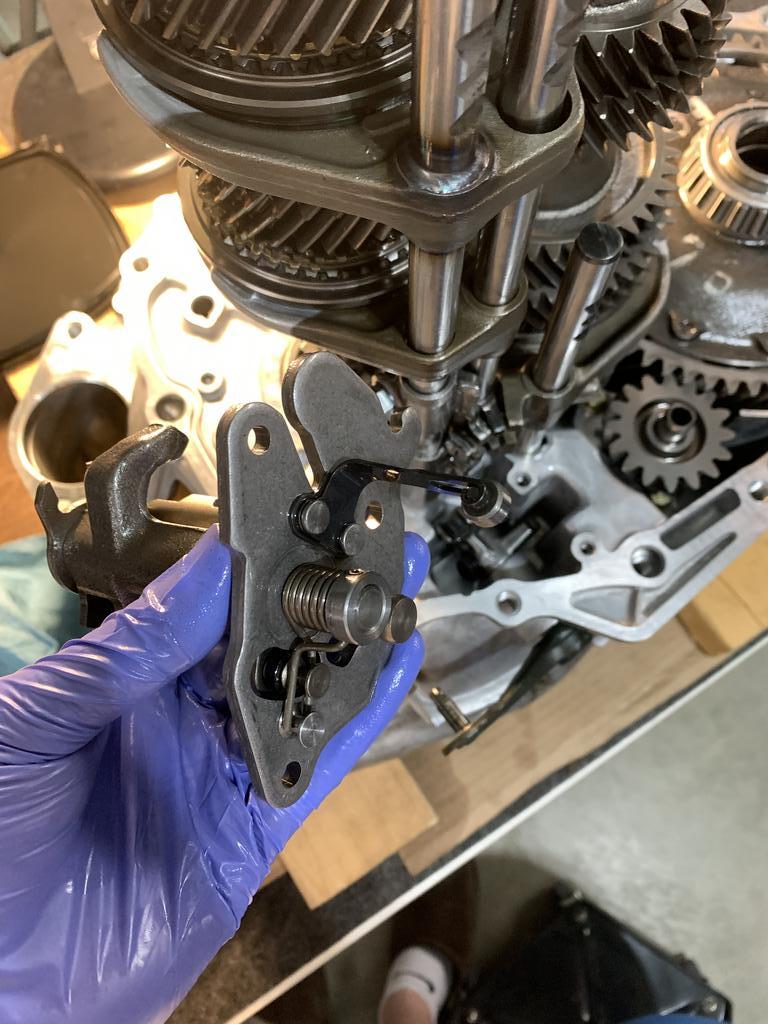

I chose to replace the spring that centers the shifter into the neutral position. All I can say is DO NOT do this if you don’t have to. That spring clip was a pain. Note the shift piece is backwards in the first photo. The second photo shows it correctly.

First the differential

Then the forum approved zip tie method for the shafts and shift forks. I can honestly say it worked great.

I chose to replace the spring that centers the shifter into the neutral position. All I can say is DO NOT do this if you don’t have to. That spring clip was a pain. Note the shift piece is backwards in the first photo. The second photo shows it correctly.