Variable Ratio Manual Rack - Feel a little F1 tech in your hands

Through our persistent effort of networking our past contacts(took over a 1yr), we are working with MVO USA on building a variable manual rack and we need your help to bring this to fruition.

MVO USA (formerly Bishop Steering Technology) produces steering gears and components for some of the world’s most elite racing series. MVO USA is the spec steering gear supplier for DTM, Super GT, and the Renault Sport Trophy (RS01) series. MVO USA also is the supplier of steering gears and steering components to numerous F1, WRC, IndyCar, NASCAR, and endurance racing teams. The quality of our products is second to none.

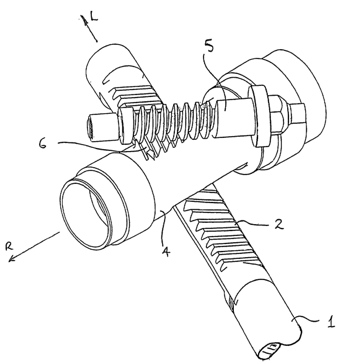

with Variable Ratio racks, MVO USA is able to offer a rack gain that changes across the length of the rack. This has many benefits for manual and power assist steering gears; such as on-center stability, reduced driver input, reduced turns lock-to-lock, and improved steering feel. When using an existing housing, our design may be limited by some of the existing dimensional constraints. http://www.mvousa.com/us/steering-technologies/steering-rack-pinion.html

Steps involved:

1)The cost for the oem rack initial assessment is ~$2500 one time fee of engineering/measuring and a feasibility study in order to detail the advantages of using Bishop steering VR technology for our car. Whether we can use the existing housing or go with a new housing etc. is unknown at this time. This means the est. price quoted below is for the internal replacement NOT including a new housing. Most likely we will go for a total replacement as the logistic of sending us your oem rack and have new internal installed has way too many variables that we have no control of and it is a nightmare we want to stay away from.

2)IFF, the initial assessment is positive and , the design cost for our NSX specific rack is ~$2500 one time.

3) Depending on the new design, a new master rack maybe required to meet the DIN 6 quality standard so it must be made and that is ~$3000 one time.

4) the existing EPS can be replaced with this but will probably need a new housing so its pending on the result of step 1.

We don't know how many of you see the value of this upgrade to improve the overall driving experience of the existing rack that is designed in the '80s. If we can pull together to go thru the 1st step, we believe the money is well spent. The turing radius most likely will not be changed as its not part of the steering geometry.

Many top teams use Bishop steering but they usually don't talk about it. Besides, its not bling so you can't tell from the outside. Just the way we like it.

The more people we are able to sign up, the less cost will be for each one of us. After Step 1-3 (~$8000).

fyi, after completion of 1-3 & pending the assessment, each rack will be sold ~$2000/ea. at qty of 100 or cheaper with more qty. MVO USA is a world class operation with expensive equipment and top notch engineers specifically making steering rack. Its not a regular machine shop so if you are thinking discount, this upgrade may not be for you.

Thx Coz, who donated an excellent condition manual rack for the assessment. Its not easy to find a top notch manufacturer willing to work with us on small qty. so we feel privileged MVO is helping us to make our car even better at all speed.

This will be for LHD only for now as our RH is busy. ....typing...:wink:

....typing...:wink:

Sign up & no money needed for now. MVO gave us the cost at qty of 100 so if we have 200+ interests, a new quote will follow.

This is the list for Step 1, the R list (as in research) a D(as in development) list as in Step 2 will follow pending the result of R.

1. liftnot(paid) 2. -m-(paid) 3. BBVNSX(paid) 4. mteele 5. greenberet(paid)

6. jagtiger(paid) 7.scammy(paid) 8.boostedtaco(paid) 9.jimminh(paid) 10. NSX-SA

11.whrdnsx 12. Gary W(paid) 13.91nsx85crx(paid) 14. SMYLDOC (PAID) 15. white98sh(paid)

16.Maxgeek(paid) 17.TURBO2GO(paid) 18.RYU(paid) 19. jwmelvin(paid) 20. v-tecpwr(paid)

21. Ghayes23 22. ediddynsx(paid) 23.Ponyboy(paid) 24. RedWings 25. Warrenw

26. A_J(paid), 27. bzyrice 28. Arc-light 29. latzke(paid) 30.mailman1 (paid)

31. nsxspdfreak(paid) 32. Sduff(paid) 33. jedi14323(paid) 34. mochanges(paid) 35. CL65 Captian

36. jsl757(paid) 37. gmeads (paid)38.jrnsx 39.prym8(paid) 40. Albert86(paid)

41. rizzo 42. 02#154 43.darock(PAID) 44.havoc_UK(paid) 45. BATMANs(paid)

46. hkz286 47. sparky(paid) 48. Nero Tenebre(paid) 49. YF-19(paid) 50. DRIFTER(paid)

51.victorhwei(paid) 52.ALWAYS4SALE (PAID) 53.Patricio(paid) 54. ryan1926(paid) 55. ApexGoblin(paid)

56. PainIs4ThaWeak(paid) 57. Jones83(PAID) 58.geometro(paid) 59.BDMalovany(paid) 60.MugenNA1

61. Xetronic(PAID) 62. BerzerkFury02(PAID) 63. Butters(PAID) 64. TrustJDM(PAID) 65. R13 66. R0Y(PAID)

Through our persistent effort of networking our past contacts(took over a 1yr), we are working with MVO USA on building a variable manual rack and we need your help to bring this to fruition.

MVO USA (formerly Bishop Steering Technology) produces steering gears and components for some of the world’s most elite racing series. MVO USA is the spec steering gear supplier for DTM, Super GT, and the Renault Sport Trophy (RS01) series. MVO USA also is the supplier of steering gears and steering components to numerous F1, WRC, IndyCar, NASCAR, and endurance racing teams. The quality of our products is second to none.

with Variable Ratio racks, MVO USA is able to offer a rack gain that changes across the length of the rack. This has many benefits for manual and power assist steering gears; such as on-center stability, reduced driver input, reduced turns lock-to-lock, and improved steering feel. When using an existing housing, our design may be limited by some of the existing dimensional constraints. http://www.mvousa.com/us/steering-technologies/steering-rack-pinion.html

Steps involved:

1)The cost for the oem rack initial assessment is ~$2500 one time fee of engineering/measuring and a feasibility study in order to detail the advantages of using Bishop steering VR technology for our car. Whether we can use the existing housing or go with a new housing etc. is unknown at this time. This means the est. price quoted below is for the internal replacement NOT including a new housing. Most likely we will go for a total replacement as the logistic of sending us your oem rack and have new internal installed has way too many variables that we have no control of and it is a nightmare we want to stay away from.

2)IFF, the initial assessment is positive and , the design cost for our NSX specific rack is ~$2500 one time.

3) Depending on the new design, a new master rack maybe required to meet the DIN 6 quality standard so it must be made and that is ~$3000 one time.

4) the existing EPS can be replaced with this but will probably need a new housing so its pending on the result of step 1.

We don't know how many of you see the value of this upgrade to improve the overall driving experience of the existing rack that is designed in the '80s. If we can pull together to go thru the 1st step, we believe the money is well spent. The turing radius most likely will not be changed as its not part of the steering geometry.

Many top teams use Bishop steering but they usually don't talk about it. Besides, its not bling so you can't tell from the outside. Just the way we like it.

The more people we are able to sign up, the less cost will be for each one of us. After Step 1-3 (~$8000).

fyi, after completion of 1-3 & pending the assessment, each rack will be sold ~$2000/ea. at qty of 100 or cheaper with more qty. MVO USA is a world class operation with expensive equipment and top notch engineers specifically making steering rack. Its not a regular machine shop so if you are thinking discount, this upgrade may not be for you.

Thx Coz, who donated an excellent condition manual rack for the assessment. Its not easy to find a top notch manufacturer willing to work with us on small qty. so we feel privileged MVO is helping us to make our car even better at all speed.

This will be for LHD only for now as our RH is busy.

Sign up & no money needed for now. MVO gave us the cost at qty of 100 so if we have 200+ interests, a new quote will follow.

This is the list for Step 1, the R list (as in research) a D(as in development) list as in Step 2 will follow pending the result of R.

1. liftnot(paid) 2. -m-(paid) 3. BBVNSX(paid) 4. mteele 5. greenberet(paid)

6. jagtiger(paid) 7.scammy(paid) 8.boostedtaco(paid) 9.jimminh(paid) 10. NSX-SA

11.whrdnsx 12. Gary W(paid) 13.91nsx85crx(paid) 14. SMYLDOC (PAID) 15. white98sh(paid)

16.Maxgeek(paid) 17.TURBO2GO(paid) 18.RYU(paid) 19. jwmelvin(paid) 20. v-tecpwr(paid)

21. Ghayes23 22. ediddynsx(paid) 23.Ponyboy(paid) 24. RedWings 25. Warrenw

26. A_J(paid), 27. bzyrice 28. Arc-light 29. latzke(paid) 30.mailman1 (paid)

31. nsxspdfreak(paid) 32. Sduff(paid) 33. jedi14323(paid) 34. mochanges(paid) 35. CL65 Captian

36. jsl757(paid) 37. gmeads (paid)38.jrnsx 39.prym8(paid) 40. Albert86(paid)

41. rizzo 42. 02#154 43.darock(PAID) 44.havoc_UK(paid) 45. BATMANs(paid)

46. hkz286 47. sparky(paid) 48. Nero Tenebre(paid) 49. YF-19(paid) 50. DRIFTER(paid)

51.victorhwei(paid) 52.ALWAYS4SALE (PAID) 53.Patricio(paid) 54. ryan1926(paid) 55. ApexGoblin(paid)

56. PainIs4ThaWeak(paid) 57. Jones83(PAID) 58.geometro(paid) 59.BDMalovany(paid) 60.MugenNA1

61. Xetronic(PAID) 62. BerzerkFury02(PAID) 63. Butters(PAID) 64. TrustJDM(PAID) 65. R13 66. R0Y(PAID)

Last edited: