It is 10k for ONE cast if that price is even still the same. I can tell you from speaking to manifold builders Joe McCarthy and Lance Hayward that the price of building a manifold will far exceed $10,000 for 10 pieces. That is a pipe dream.

-

Protip: Profile posts are public! Use Conversations to message other members privately. Everyone can see the content of a profile post.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DMS Performance intake manifold

- Thread starter dmscrx

- Start date

My understanding is that:

One can expand the flow from a noncircular (e.g. elliptical) section harder (less loss). But it's not clear what port you are implying in this manifold would/should be noncircular. The expansion in an intake with a scoop generally happens before the filter, to manage the pressure drop across the filter.

As I believe greenberet has pointed out in the past, NA intake performance is generally dominated by acoustics within the intake. And FI performance is more about avoiding loss, as you allude to. I suppose that your comments make sense in light of your FI setup. And perhaps the loss characteristics of this intake will become more important for a FI setup.

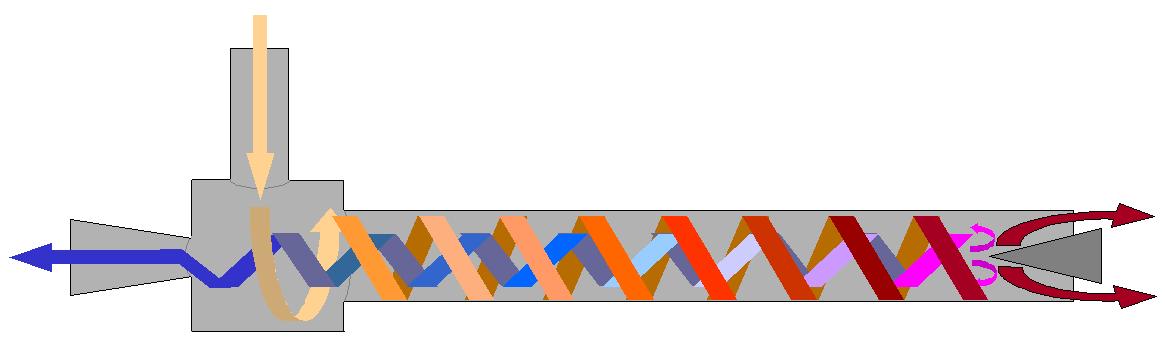

This is the best image that I can find to illustrate my point about tube vortexes slowing down port velocities:

The manifold is designed with round bellmouths at the entry and changes to a "D" shape for entry into the cylinder head. The reason this was done and not a full on D shape runner was 1. cost and 2. space. The V8 world has the luxury of spacing between intake ports to allow for such large runners. Some of them are even rectangular and are more tall than wide which provides even better spacing for that design. Not saying they wouldn't fit, but if they were to be d shaped and have a velocity stack built into each runner for the entry then they run the risk of being too close together in the plenum which isn't good for airflow and they may also hit each other. I had to make sacrifices somewhere and designing this thing with a budget in mind could not make it exactly how I wanted. I really wanted curved runners to compliment my design, but again too costly. The runners alone would have cost $1500 by themselves for billet ones. This is the design I made (more or less) from the side view minus the curved runners. This has proven to be one of the best designs in both FEA and real world data. It's currently on the fastest FWD Honda at the moment (Speedfactory) It is also similar in design to the Ferrari 458 Speciale manifold as well

Cast is the best method to make things cheaper, but it creates a huge expense on my end to get it built. I am a small business and just simply cannot do such things. This is my attempt to create something that has been absent from the NSX world for so long and the engine definitely needs a product like this.

- - - Updated - - -

This looks like something Wilson manifolds would build haha. They have some of the best quality manifolds out there. If you are an NSX owner and have an unlimited budget, they will build a manifold for your engine that will destroy mine. After you pay them $7500.00 though. That was the quote they gave me when I first inquired

Cast is the best method to make things cheaper, but it creates a huge expense on my end to get it built. I am a small business and just simply cannot do such things. This is my attempt to create something that has been absent from the NSX world for so long and the engine definitely needs a product like this.

- - - Updated - - -

The OP manifold does have edges that aren't smooth, but that is part of the price you pay to keep the price down. The edges aren't detrimental to losses all across the curve. They would be minimal unless I saw otherwise. I've seen square manifolds produce on different cylinder engines before. Especially when a turbo is introduced into the equation.

The cost of something like this to remove the edges of the manifold would not be worth the minimal gains you received.

The other thing to remember is that your fears and theories mean nothing because of his real world data. There are books that contradict many techniques and designs in the racing industry, but real world test will always be the absolute. His manifold is showing good gains across the board. That can not be disputed. Definitely needs more testing however.

It is from my understanding that oval ports flow better than circular ports but they give up velocity unlike a circular port. I believe nascar runs oval exhaust for instance over circular. Circular pipe is only really made due to it's strength, not flow rate.

This looks like something Wilson manifolds would build haha. They have some of the best quality manifolds out there. If you are an NSX owner and have an unlimited budget, they will build a manifold for your engine that will destroy mine. After you pay them $7500.00 though. That was the quote they gave me when I first inquired

Last edited:

I was with you on what you were saying until you said your manifold is similar to the 458 Speciale. The split plenum with a bridge from what I have seen is the better design for 6/8/10 cylinders.

That Skunk2 Ultra Manifold is making some good numbers on cars. It isn't the best manifold out there, but it is a sponsor of Speedfactory. lol The IPS manifold made by Hayward is the best manifold consistantly.

I was with you on what you were saying until you said your manifold is similar to the 458 Speciale. The split plenum with a bridge from what I have seen is the better design for 6/8/10 cylinders.

That Skunk2 Ultra Manifold is making some good numbers on cars. It isn't the best manifold out there, but it is a sponsor of Speedfactory. lol The IPS manifold made by Hayward is the best manifold consistantly.

Haha I wasn't talking about the design in that way, just the general plenum shape from the side view (see previous post) The Ultra series manifold picture shows a better example. Speedfactory picked up close to 60whp over their previous intake manifold (according to James) so the design is a good one. The IPS manifolds are good, but the only data I have on them comes from the K series. Speedfactory is running a B series on their fastest car

This is a better view of what I'm referring to: (wish I could find a better pic)

How much for just the larger fuel rails? Will they work with the stock manifold and what size tube/threads is it? (-6, -8?)

How much for just the larger fuel rails? Will they work with the stock manifold and what size tube/threads is it? (-6, -8?)

I don't know just yet. The ones I have currently were purchased from a prime member last year. The company producing my manifolds for me is supposed to have a copy of them when they copied my manifold design. I will have to see what the individual pricing for them is going to be. I just told them a budget to adhere to for the total package. They are -8 fittings though.

- - - Updated - - -

Any word on more testing with the manifold?

Yeah, I've put about 600 miles on it so far and everything is fine. I am putting it back on the dyno tomorrow as I have converted it to flex fuel. I will be getting an ETA on the production version of the manifold soon.

Last edited:

Thanks. Would love to see the overlay of the gains of (E85?) on your setup.

May Joe McCarthy RIP.It is 10k for ONE cast if that price is even still the same. I can tell you from speaking to manifold builders Joe McCarthy and Lance Hayward that the price of building a manifold will far exceed $10,000 for 10 pieces. That is a pipe dream.

The aluminum foundries (Edelbrock has one out in the desert, and BuddyBar has one in LA County) will typically want $$$ to create the mold, and then they're going to want a minimum of X units. In addition, there are costs associated with getting a design engineer to translate the piece (in this case, an intake manifold) into numbers/coordinates that get punched into a computer.Definitely not cheap.

20yr ago was $14k+ for a small batch of cast V6 manifold for Nissan GTP made out of mag. Ouch!

RIP Joe.

RIP Joe.

Last edited:

Thanks. Would love to see the overlay of the gains of (E85?) on your setup.

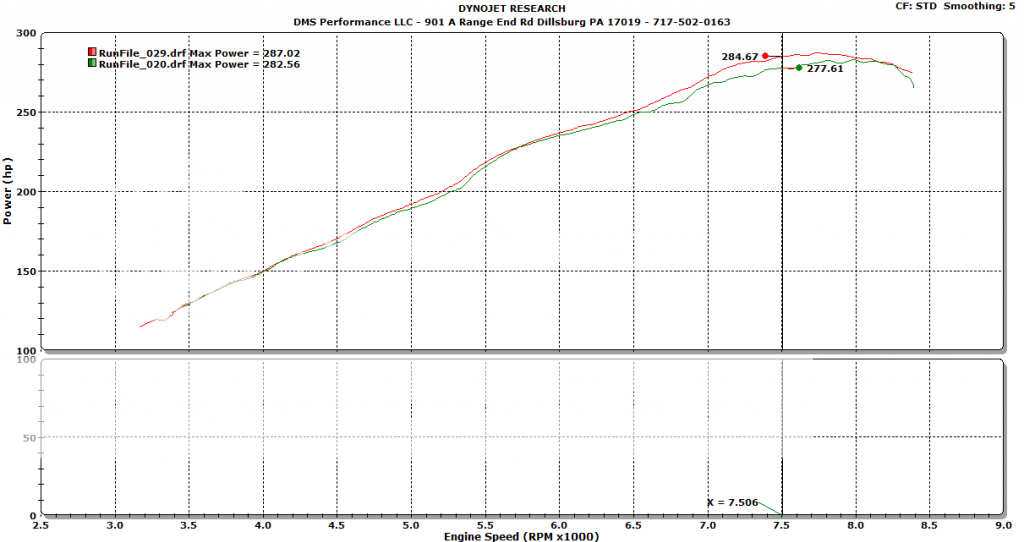

Grrr. Wish it was full E85 as I used what was left of my winter blend here. The ratio according to the Infinity was between 70-71 percent. Gains would have been a little more if it was at 85 percent. I will have to put it on again when I have time. That being said there were still gains..

Power comparison:

Power and Tq comparison:

Old manifold Vs New and ethanol full comparison:

Run conditions this time:

Ambient temp 76.78 F Humidity 31 percent

Intake temps starting at 33C (91 degrees F) and ending at 27C (80 degrees F)

Intake manifold surface temperature between 105 and 111 degrees F according to infared

Have you had time to play with the intake sizes? Also, are you any closer to finalizing a time period for the sale of the intake manifold?

I'll play with the intake size once I test the retail version of the manifold, which I will have an ETA on shortly.

Black anodized would be nice, and with mounts/provision for the Honda Motor Co. cover plate. I think an aftermarket ECU is going to limit the market for this product (just like ITB)- perhaps reach out to Prospeed or SOS to see if they might be willing to tune the stock ECU for it? Would we need to go up to 270cc injectors, or can the stock 240's handle the extra airflow?

Black anodized would be nice, and with mounts/provision for the Honda Motor Co. cover plate. I think an aftermarket ECU is going to limit the market for this product (just like ITB)- perhaps reach out to Prospeed or SOS to see if they might be willing to tune the stock ECU for it? Would we need to go up to 270cc injectors, or can the stock 240's handle the extra airflow?

RDX injectors + AEM infinity = ???

SLS may be another manufacturing method for a manifold of limited production and can support more complicated part geometry...

Black anodized would be nice, and with mounts/provision for the Honda Motor Co. cover plate. I think an aftermarket ECU is going to limit the market for this product (just like ITB)- perhaps reach out to Prospeed or SOS to see if they might be willing to tune the stock ECU for it? Would we need to go up to 270cc injectors, or can the stock 240's handle the extra airflow?

The company producing these for me does anodize so that may be an option but it will cost more for that. I am playing with the idea of having the NSX logo machined to the top of the plenum. If I do that it will be limited to the first 10 or so. The company making these wants their name on them eventually since they are using their machines and resources so I will give them that down the road. It would be easy to make the factory cover mount to it so I can do that in house for the select few that want it. Unfortunately, the stock injectors run out of headroom at the rpm this manifold works so I highly recommend an upgrade. 270s should work depending on power output. Those running a 2.25 or 2.5 inch exhaust should make more power than I did so that has to be accounted for as well. Always run a little bit bigger injector than you need. Anything that makes good power is going to need tuned to be reliable; I wish we lived in a world that we could bolt up infinite parts to the engine and make more power on the stock computer without tuning

Last edited:

I have been glued to this thread since the beginning. You have done a sensational job with your manifold. It would be great to see collaboration between your work and Prospeed's RDX injectors with a tune to maximize the union. That really would be something for us NA guys.

I'm fine with not using the OEM injectors since i run the RDX ones and have an aftermarket ecu going in shortly, quick question does the RDX injectors fit or would we need something else?

I'm fine with not using the OEM injectors since i run the RDX ones and have an aftermarket ecu going in shortly, quick question does the RDX injectors fit or would we need something else?

They should fit. Might have to do some fitment with the O-rings, but the bodies will work.

- - - Updated - - -

I just want to let everyone know I have applied for Vendor status. I have a few other items for the NSX I can contribute as a vendor aside from the intake manifold so I will start there. I have paid my dues and am awaiting approval. Once that is completed I will start a group buy thread for the intake manifold.

Last edited:

this + rdx injectors + headers + intake scoop = 300 whp NA?

this + rdx injectors + headers + intake scoop = 300 whp NA?

I'm at 278whp with all of those (minus this manifold but plus a ported and polished manifold) so I don't think that's achievable, although that was also my goal. Maybe with the right throttle body and test conditions in cold weather you could hit that on the dyno...

Similar threads

- Replies

- 3

- Views

- 188

- Replies

- 6

- Views

- 425